Hi everyone,

I make bracelet cuffs from aluminium and I put different designs on them either by enraving or dye sub.

I really want to do a process called photo anodizing but I want to know if anyone knows someone that can do it for me. It seems as though the process is super complicated and involves some dangerous products and electricity and I’m concerned for my children and grandchildren touching the product.

So what I want is to to find someone that can photoanodize my vector file on to a colored cuff.

Does anyone know someone that does that?

I am more curious about the answers to your questions than I am about doing what you want to do. I just started anodizing Niobium and Titanium. It’s a lot of fun and not horribly involved from a how to do it point of view. Using it creatively is another story, at least for me. Don’t be too worried about the electrical side of anodizing. As long as you follow the safety rules, you should be fine. I buy my anodizing materials and tools from Reactive Metals. I am not sure if they support what you want to do, but give them a call. They may be able to refer you to someone who does. Good luck…Rob

Hello, I made jewellery from anodised alumimium but I don’t understand what You want to do print Your design on already dyed aluminium or print color and design too anodised aluminium ? From what I known it is very hard to find information about this process from the internet, I start from Carol Stiles book " Anodized ". You can contact me through Ganoksin or pawelbielawski@gmail.com.

There is a way to do what you want relatively easily and without dangerous chemicals.

A very long time ago I took a silk-screening class and made a photo resist to silk-screen a print. The same process can work for you. It isn’t that involved.

I can’t remember the name of the resist material, but others on Orchid likely can. It involves some kind of plastic sheet that you develop with ultraviolet light to make a resist for etching.

For the photography part you need a mask with many dots. Sorry I can’t be more specific - it’s been a long time. The expensive version would be a glass plate with very fine lines scored horizontally and vertically to leave many, many fine lens-like pyramids. The cheap version I used was basically just a black negative with very many tiny clear dots. You would be doing what newspapers do to print photos - not gray scale as in a black & white print, but lots of tiny dots, like in the comics.

You would project your image onto the resist with the dot negative against it, attach the resist sheet to your metal, develop it, then do the anodizing, and wash the resist away.

Other than the anodizing, which is not dangerous, you need the resist sheet, UV light, and the dot negative. Sorry I can’t give it a better name for that to search on. One of the large photo stores like B&H Photo might be able to help there. A print shop that uses presses might, as well.

It is also possible to laser print the ‘dot’ image, but that involves getting a laser cutter and software. Possibly https://darklylabs.com/ or others that sell such machines can put you in touch with users who might print for you. Or search their forums and contact a user directly.

Neil A

Anodising aluminium is simply but you need nasty chemicals :1 galon of sulfuric acid + nitric acid + caustic soda , DC source and lead sheet as a cathode and it take 1.5 h to anodised ~7x9 inch piece of aluminium. I think that Neil A idea should not work , dying aluminium is posibly only after anodising proces when pores are open and later must be sealed to close pores with dye particles inside the metal.

Pawel Bielawski

My apology for suggesting that strong chemicals don’t need to be used. I have anodized titanium without using harsh chemicals, assumed it worked the same way with aluminum. Apparently not.

Neil A

As always ,mens discus technical aspect when women neeed simply answer and help  I think that I can help if Elissa send more information and maybe a photo.

I think that I can help if Elissa send more information and maybe a photo.

Pawel Bielawski

Hi thanks for the advice. I spoke to reactive metals but unfortunately they could not offer any help at all.

Hello there,

Thanks for trying to help me solve this problem.

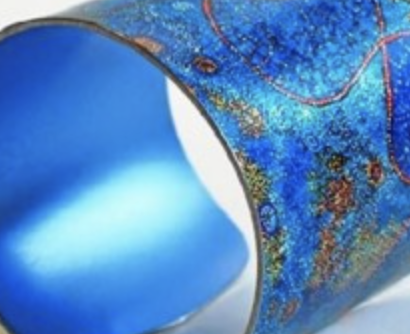

Well let me show you a picture of what I do already with dye sublimation. The problem is that this is delicate and the edges can chip.

and what I want to do is to have the picture cast in to the metal by photo anodizing as per this second picture and be able to color the inside.

I hope you can see the pictures properly

I look forward to your suggestions.

Thanks

Hello . this is photo of the bracelet I made. My proces : 1.anodizing raw aluminium sheet /not sealed/ 2.transfer design with heat press on both sides of the sheet 3.seal aluminium in boiling water 4.cutting and forming . First question I have it is what kind od aluminium You use ? If You have anodized aluminium which is already sealed You can transfer image to it but it is not cast inside the metal.I think that I can transfer Your design to aluminium if You have problem with it.

Pawel BielawskiYes this is exactly what I want to do!!

I currently use coated aluminium or pre anodised coated aluminium to do the process via dye sublimation. As I say it’s not ideal because it cracks.

I would love your help to show me how to put my pictures on via anodizing.

Thanks

Elissa

My issue is the transfer with heat press part. Right now I do the transfer by sublimation on raw aluminum treated on one side so that I can sublimate. Is that how you would do it? I don’t know another way of doing it. My problem here is that it seems to crack on the edges and sometimes when I bend the metal if it’s not timed exactly. So it seems to me that your method is better for transfering the image.