I recently purchased some lovely pattern wire from Rio to create rings. Using this wire is new to me. It has lots of small detail which I love but I’m having a problem with getting the join flush.

Here’s a bit of my process: I saw the join on a diagonal and line up the 1mm cable pattern on top and bottom of the wire (there are tiny vertical bars) . The wire is bent so that it is flat when I saw the join (not rounded as in a ring shank) . My thinking is that this is the best way to keep the join flush at both ends. When I refine the join I keep the wire parallel as well.

The pattern is irregular at the join and it’s very challenging to get both sides to fit. I have no problem with getting an excellent join on round wire. Just can’t get a good flush fit solder join with this product.

When I form and solder the ring, there is a slight bit of the pattern that’s off making the join is too apparent. Should I try to use gravers to clean this up? (I don’t have great graver skills.) Or is re-sawing the soldered join and resoldering it the best way to go?

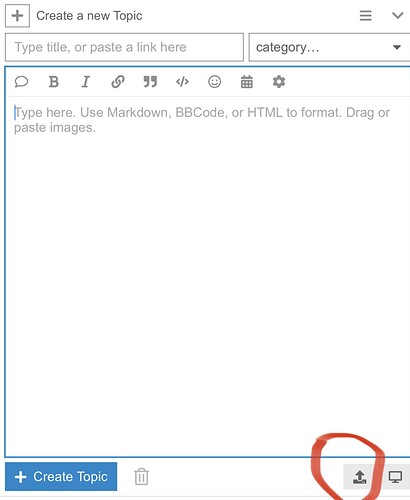

My aim is to get a better sawed join to begin with and avoid the mismatch solder join with this new product I’m working with. Wish I could add an image here.

Thanks,

Joanne