The need for many small pieces of sheet cut the same way has rekindled my interest in making pancake dies. I reviewed a lot of what is in the archives, some of which I was a part of, but I can’t find a reference to how to calculate the cutting angle. After doing a lot of drawing and resurrecting my now nearly 60 year old knowledge of geometry and trigonometry, I think that it is as simple as calculating the decimal value of the width of the cutting blade divided by the width of the die stock and looking that value up on a sine table. This calculation comes close to what I find on different tables that show the cutting angle for different blade size and die stock width combinations. I think that there are fudge factors for soft vs. tool steel and weather or not the die will be hardened, but my calculations are close. I find a lot of phone apps that will display the angle of a surface away from level. This is an easy way to set my adjustable bench pin to the right cutting angle. Can anyone confirm this calculation is correct or tell me where my memory and/or logic has failed? Thanks…Rob

On page 15, there is an illustration of gauges and angles, but no formulae. https://silversmithblogdotcom.files.wordpress.com/2014/05/project-report-no-12e_1-the-r-t-blanking-system-may-1980.pdf

I really should have had a cup of coffee before I tried to respond to this. I’ve forgotten all of my trig formulas too, so I had to look this up. Since we have the side and the opposite, I believe we need to use the inverse tangent function to determine the angle of the hypotenuse. I found this page to help me understand, rather than pull out the old geometry books! Finding an Angle in a Right Angled Triangle

I am just drinking my coffee now, I hope that you got yours. Thanks for your very helpful reply. I am retired and spend all together too much time trying to figure things out. This is a real challenge for me if it requires that I recall, what is for me, very old math information. I will review the RT blanking information and see what it has to tell me. In the end, I can cut out dies that work for me, I am just trying to figure out how an why they work. thanks again…Rob

I just read some earlier post where it was explained that the cutting angle is a function of the width of the saw blade and the width of the material that is being cut. These two dimensions are the length of two sides of a right triangle. Using basic trigonometry, you can calculate the sawing angle. I notice that adjustments are made for tool vs. mild steel and whether or not the die will be heat treated. This answers my original question. After cutting a number of practice dies and going through all of my 3/0 blades, I left with two questions. What is the best blade to buy by the gross and is there a minimum size cut angle where the die won’t be able to support itself. Attached should be a picture of my latest practice die with an arrow pointing to the area that is a problem. I am using 18 gauge mild steel. There isn’t enough metal to support a cutting edge. Any suggestions are appreciated…Rob

This should read 16 gauge, not 18 gauge. I originally started with 18 gauge, but bought 16 gauge from my local welding shop.

hi,

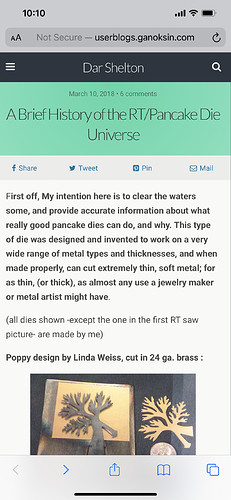

did you run across this blog post by dar shelton of sheltech…has some interesting info

http://userblogs.ganoksin.com/sheltech/2018/03/10/real-pancakert-die-real-pancake-die/

julie

I can’t open the link, but I have read a lot of what Dar, Kevin Potter and others have written. There is a lot, especially from 10+ years ago. I have discovered that, at least for me, creating a design first and then trying to cut it out is the way to go. Successes and failures will help me figure this out. In the end I am just trying to add blanking dies to my tool box of knowledge and experience. I do need to buy a lot of blades because I am going through them. Thanks…Rob

hi,

ok

perhaps you could just search it in web

“A brief history of rt pancake die universe”

lots of diagrams re angles…

julie

Found it, thanks!..Rob

hi,

were you able to copy/paste this link, that was noted in the blog?

very technical

(or could type it into web search)

julie

I was, thank you…Rob

i experimented a bit with these back in the '90’s. A clever friend created a jig with an attached saw frame that could be adjusted to the correct angle. all you have to do is use the c-clamp to attach to a table, insert your steel (with a pre-drilled hole for the saw blade) and saw away. the adjustable ‘table’ of the contraption takes care of the need for consistency of the angle. I will try to add a photo I would love to sell this along with some of the steel. if you are interested email me: bbbsimon@comcast.net

i experimented a bit with these back in the '90’s. A clever friend created a jig with an attached saw frame that could be adjusted to the correct angle. all you have to do is use the c-clamp to attach to a table, insert your steel (with a pre-drilled hole for the saw blade) and saw away. the adjustable ‘table’ of the contraption takes care of the need for consistency of the angle. I will try to add a photo I would love to sell this along with some of the steel. if you are interested email me: bbbsimon@comcast.net

Rob, sorry I missed this thread. I’ve been too addicted to Facebook, using the excuse that I have a group there (which I shall now shamelessly plug (Dar Shelton’s Pancake Die Paradise | Facebook) ?.

You have it mostly right, but real life doesn’t match up with the mathematically correct way to determine the sawing angle. I found out in the beginning that I had to add a few degrees to the (I used graph paper and a protractor) theorized angle to end up with tight dies. I can’t say completely or exactly why this is. Some of it may be the difference between the measured width of a blade and the actual gap it leaves behind (but blades fit tightly in cuts they’ve just made). Some of it is because of heat treating, and the small amount of metal lost to oxidation. Those two possibilities are obvious , but don’t come close to explaining the 2-4 degrees more that I use.

Anyway, I make them very, very tight, often past that point of zero clearance, so that when I break them in after cooking, a tiny sliver shears off of the cutting edges. This explains a lot more of the angle difference “required”.

As far as how much angle is too much, there’s no right answer, really, but I can generalize by saying that for heat treated dies, you can use more angle than you probably are comfortable with, sawing. The most I use is around 24 degrees, cutting 3/64" 0-1, or .050" 4130 steel with large blades. I haven’t seen much in the way of deformation issues because of the angle. It’s more about long, thin, pointy areas, like the spaces between the petals on your clover here. Maybe widen such gaps in the design, use a larger blade that’s easier to saw with, than fret over the angle, BUT with smaller blades and less angle, you retain more mass in a given narrow area, than if you have the same narrowness and use larger blades with more angle.

As far as blades, the Platinum ones are the hardest (Pike Platinum, Sierra for Platinum from Contenti) and saw steel the best, fastest, longest, BUT they’ve been discontinued. I hoarded a literal mile of them when I found out, over $2K worth. Those blades are my life. However, other blades are good, but not great. Laser blades (not laser Gold) from Rio, regular Pike or the new Super Pike, and Glardon Vallorbe. I called the manufacturer of Platinums a while back, and they gave me a long list of the brands they make.

I plan to frequent Orchid more often again, starting now, so feel free to ask me anything about the dies.

Dar

That’s a LOT like the old Bonny Doon saw guide, versions of which I’ve used since the 90’s. Sound concepts (saw guides replaces by saws from Knew Concepts)

DS

Feed me specific combos of steel and blade size, and I can try to spit out useful angles. see long post from today re: why calculations aren’t perfect for making tight dies that cut thin metal cleanly. I don’t have tables of my own. I have piles of years of disorganized notes about the hundreds of angles I’ve used, many of which make sense to me ![]()