Jeff

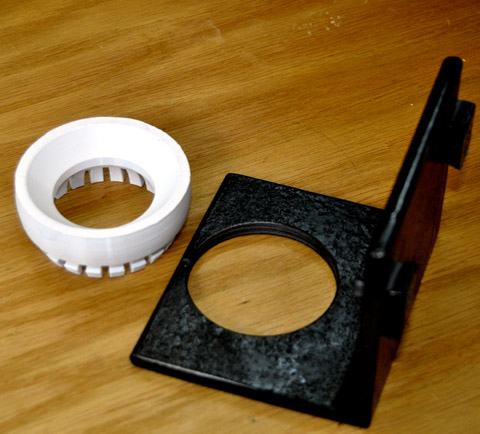

For portability, try the GRS mini ball. People have complained that the small ball lacks stability. I have solved that problem. I made a holder from 4" x 4" angle iron with a 3D printed seat that just snaps in.Now the seat doesn’t slide. Don’t use my B

enchmate any more. This is so unbelievably manuverable with just fingertip pressures. I have 4 other engraving balls but this is my favorite. I also have one of the knockoff balls I bought on ebay for less than $100. Works well. If anyone is interested, I will provide construction details and an STL file (If I can load it on here)

That’s awesome! What a great idea to make the doughnut seat snap into the shelf. You’re a genius!

Thanks ericgem!!

This is genius. I have the GRS shelf to put my small ball on. There is “drift” if I’m trying to use a punch and hammer to tighten bezels and such. This would stop the ball from moving. I would love a copy of the STL file for sure if you can.

Thank you.

ballrest.stl (8.1 MB)

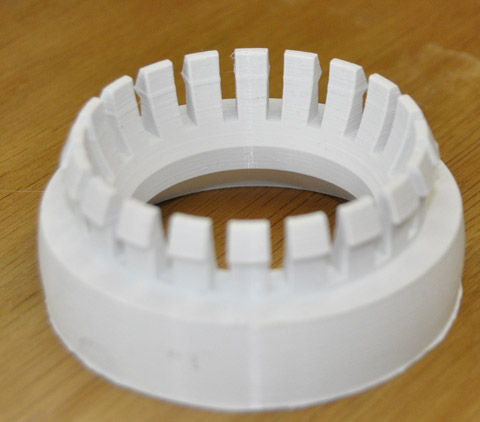

Here is the STL.I made the fit a little sloppy because my metal was thick. You might want to scale slightly. If you want to play with it, I can send a Rhino file. I should make another thinner shelf like the GRS. The beauty of the small 4" shelf is it puts the working surface right up at benchpin level, and you can easily take it off and on with one hand. I made the little GRS bevels on the back with my Bridgeport mill, but you can probably buy them from GRS. Or just file them up from bar stock. Drill your hole with 2 1/8" hole saw. Needs to run slow. Most drill presses are too fast. I used the mill. You can use a hand held electric drill which will run slower. Takes a while to cut through. I printed on a Prusa FDM PLA but could be done resin.

Dave

Sorry. Just checked again. 2 1/2" hole saw. Print the plastic flat with the prongs up. No supports needed. When you put it in the hole, put a board or something on top to distribute the pressure. Support the shelf with room under the hole. Hit with a big hammer, or better yet use an arbor press.

Very nice. Now I need a 3D printer…. ![]()

Hi,

i agree…the micro ball was a bit too light for me…i ended up with the heavier micro xl, and like it.

julie

I have the GRS standard and when I am pushing heavy bezels, the ball moves around on the base sometimes. My solution is to remove the removable pins bases and if that doesn’t work, I go to my machinists vise. Another reason why I wish that I had purchased a Lindsay vise, but they were out of stock at the time…Rob

Can you explain why a Lindsay vice would be better?

The circumference of the circle at the bottom of the Lindsay vise appears smaller, supported by a machined base and looks like it would be less inclined to move when I use a hammer and punch to move a heavy bezel. My GRS sits on what looks like a small rubber tire with plastic dots to support the vise. That’s the logical answer applying the physics that I taught for years. The real answer is that I just like his stuff…Rob

I can’t tell from the pictures if I’d like the Lindsay engraving block or not? They look very different from the GRS, Victor and similar blocks. I’ll have to try one someday at at trade show.

Rob, you probably know this, but just in case. The GRS rubber gravers block doughnut holder has two sides. One side had teflon dots to facilitate the graver moving in every direction. The other side is just rubber. That side kind of locks the gravers block in place to make it be more vise-like. The rubber only side doesn’t completely lock the graver in place, but it definitely helps. I use the rubber only side for hammer setting and similar needs.

Jeff

I have attached one of these printed seats to the large GRS shelf for another jeweler here. She wanted it lower for her use with the microscope. Has another one mounted higher with the small shelf. If it gets in the way when using the scope she can easily lift it off.

Thanks, I did not know that, but should have figured it out. I will go down right now and flip it over. That all being said, Steve Lindsay’s vises are all works of art. Thanks again…Rob

I used my GRS gravers ball for years without knowing that the rubber doughnut stand had two sides one “lubricated”, the other “sticky”. My mind was blown!

Jeff

Hi,

and, just in case…i wanted to mention…there is a screw to adjust the rotational tension ad well…to lock it from spinning…or spin less freely…

julie

Yes, thanks for mentioning that! It’s an excellent feature that not every block has! I’ve only looked at the bearings in GRS blocks and Victor blocks. But I also really like the quality of the GRS bearing.

Thanks Julie!

Jeff

do not buy the chinese cheapeast. version of the grs they are junk . just save you money and buy the real deal

Hi,

i wanted to mention…for the grs micro and micro xl ball vices, there is a hard plastic base (which is more prone to sliding around) as well as a rubber base (which is less prone to sliding around)…

if i recall correctly, the micro comes with only the plastic base, and the micro xl comes with both the plastic and rubber base…the rubber base is also sold separately…you may have to call grs to get the item number…the website can be somewhat elusive…

…i had originally ordered the micro, but exchanged it for the micro xl…and that is when i learned of the rubber base…it was mentioned as a possible solution for my micro dissatisfaction. GRS support is amazing!

the plastic base allows for more movement

the rubber base provides some friction

(in terms of ball moving on the base, as well as base moving on the bench/ bench shelf, etc)

i originally bought the micro ball, but found it to be too unstable if more than a little force was used…the micro xl is a bit bigger and heavier, and i found it to be more stable…also, because it is bigger/ wider, the jaws open wider and dont fall off when opening them up to get a ring out of a ring fixture…

if you are using tall fixtures, when tilting the 4.4lb micro ball on a either base, at a certain point, the smaller size becomes more of a liability than a benefit…the 7lb micro xl on a rubber base is a bit bigger, heavier, and in my opinion more stable…

for more forceful work i prefer the grs standard ball, which is much heavier, more stable and provides a more solid deadblow…

micro block is 4.4lbs

micro xl block is 7lbs

standard block id 20 lbs

julie