Hey there all hoping someone may be able to shed some light on an

issue that has come up with my latest attempt at a mokume laminate.

The billet consisted of 7 layers of sterling silver, 2 layers of

gilding metal and 4 layers of copper. The thickness of each layer was

about 1.5mm (with a base layer of silver at 3mm) making the total

thickness around 20mm, and they where 70mm x 90mm.

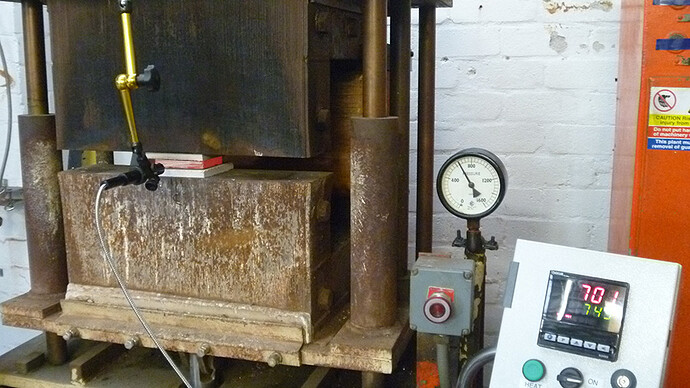

The stack was heated at 740 c for about 25mins under 610 psi of

pressure. No shielding atmosphere was used but the metal was fluxed

and under that much pressure that it should not be an issue.

After heating the billet was forged around the edges until cool and

seemed to have bonded fine. This was proven when i trimmed the edges

and all layers where shown to be bonded.

Now is where the problems showed up on the third pass through the

rolling mill, not working it very hard for fear of it falling apart,

the middle layer of copper seems to have failed. The bond seems okay

as there is still copper on the silver either side but the copper

itself seems to have fallen apart.

Just hoping someone out here may have some idea as to what went

wrong. I’m suspecting that perhaps the temp was a bit to high and

held for too long and the grain structure has grown to much,

something that could possibly be solved by forging more rather than

rolling. Or the other thing that occurred to me is that I didn’t

anneal before rolling after forging but being the middle layer that

has failed and having not been reduced that much in the forging

process i’m not so sure about this.

Anyway i’ve attached some images of the billet cooking, the billet

prior to rolling and the resulting failure. Any advice would be

greatly appreciated as this is rather frustrating with the

quantities of silver i’m experimenting with.

Ben Pearce