Here’s a question a friend asked me but I couldn’t think of any good answers. What do you guys think?

Here’s the question:

I was wondering if you could help a little. I’m having a major problem with silver tarnishing in relatively short time, under 2-3 days. It’s driving me absolutely insane. Starting to get a little stressed over the issue as the summer is closing in and while I should be creating new products for sale, I now spend my time cleaning the already polished silver.

Have tried everything I can think of from storing in air tight bags with anti-tarnish strips to changing the water supply to distilled water, cleaned the tumbling barrel, used several different coatings (which makes things worse, as it will tarnish underneath the coating). Ugh! Is there anything else I could try? Tested some products to clean the jewerly (Hagerty etc.), but the chemicals seems to be quite harsh and it actually speeds up the tarnishing.

Should I invest into silver plating? Could that at least slow the process somewhat?

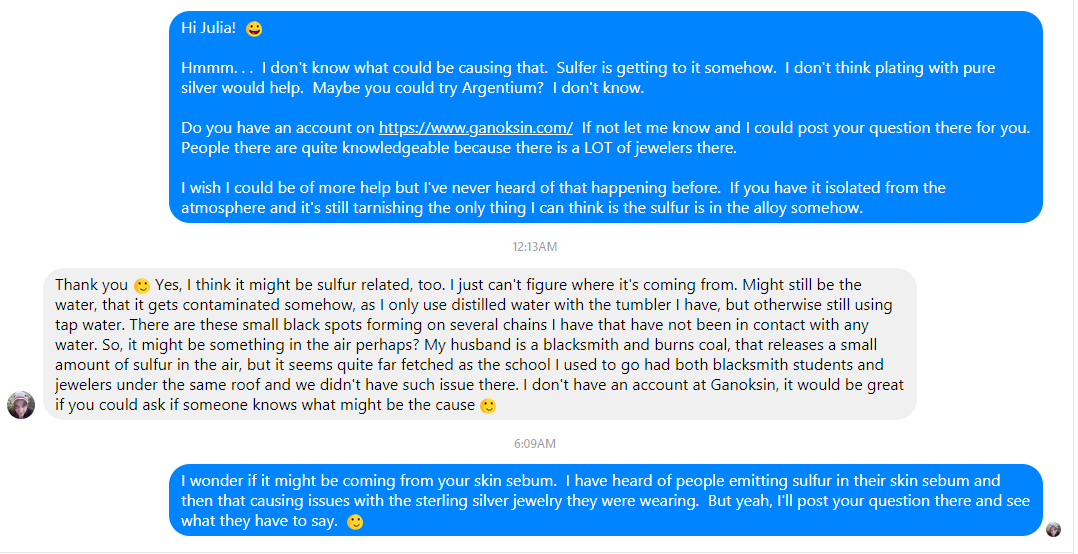

Here’s a screen cap of our discussion so far.

There is another approach to this problem. It may not be the silver but the environment it is in. Try giving a piece to a friend and see if it does the same in their house/workshop.

It’s possible that there is a contaminant nearby.

Tony Konrath

tonykonrath@mac.com

2 Likes

Seems like it would have to be the environment, don’t you think? Even with looking at the volcano disaster in Hawaii, and all the sulphur dioxide in the air, i was thinking everybody’s silver is tarnishing over there! (Yes, that’s how my tiny prehistoric brain is working.) I had a client whose silver earring components turned black as coal, and I have jewelry display cases that seem to blacken them. I know some of the wood composites under the velvet have formaldehyde and other stuff which are suspect.

But: what about depletion gilding, so as to raise the fine silver to the surface? And, Argentium is much more resistant to tarnish.

1 Like

You’d want to use a rhodium plating since it then won’t tarnish.

When I take my rings, bangles off at my desk and put them on a ring holder just under the LED monitor they tarnish in a couple of days! What’s more a vintage slide rule/angle finder made of steel corroded badly with rust! It had been behind the monitor a couple months at least. There is an external hard drive there too so I’m not sure which one causing the tarnish, one of them for certain!

Aurora

I only make silver jewelry in Argentium. When I finish making and polishing the piece, I place it in the kiln at 212 degrees F. for 3 hours. That germanium layer really helps prevent tarnishing.

Not only that… have you seen how brilliantly white Argentium silver looks compared to regular sterling? I wish I could show people who have never seen finished Argentium an organic conch pendant I made for my wife how white and shiny it is. I think I got lucky on that piece and didn’t screw things up like I normally do. But I can’t imagine a whiter silver alloy besides 99% silver.

Some jewelers use the silver alloy that has touch of platinum in it to keep it even more tarnish resistant. I’m not expert in metals like Mr. Binnion here on the forum but my guess is that since pure silver is the most reflective metal, it is possible that the Argentium pro alloy that is 96% pure silver is actually more white and more bright than the much more expensive continuum silver alloy. I don’t know this for sure but I would not be surprised.

Either way, you can’t beat the look and the price of properly prepared argentium. It would be interesting to scientifically weigh if argentium is more white than continuum. Although, maybe the continuum would be able to get wet more or exposed in chlorine pools.

2 Likes