Thanks for your input Rob.

I’ll respond to your well worded advice step by step, so it will be easier to tie it together.

Your original post mentions that you have no experience with jewelry, but you don’t mention what metal you want to cast.

I’m a bit shy on this one, as it will probably result in a massive outcry, but here it is:

My plan is to cast the ring in pure Rhodium of reasons not important to this discussion.

I’m fully aware of the massive set of challenges regarding this (Maybe not all the issues but that there are massive obstacles.)

I know it has been done and have reached out to two that have done it, but one has retired and one does not seem to be accessible. Metal and stone has already been purchased.

Assuming that your 3D print is in some form of wax that can be burned out, take it to someone who will do this for you.

My Idea was to print it in wax, but so far I’m not happy with the finish, so i will polish and modify the print and make a silicone/rubber mold to cast wax models.

You are still left with the basic task of cleaning up the casting, polishing it and hoping that it fits. If you want to make jewelry, you might start with fabrication.

I think fabrication will be difficult regarding Rhodium, due to brittleness.

Correct me if I’m wrong

There will be post casting soldering though, since the prong/stone setting mechanism has to be produced in an alloy soft enough to be formed without cracking.

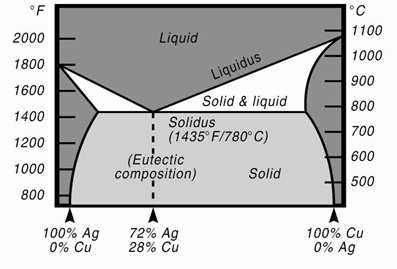

Pt90Rh10 or Pt70/Rh30 are both standard alloys.

It is a bit less tool dependent and many of the tools that you will acquire will be needed to finish a casting. Doing this you will get a feel for how precious metal behaves and how get it to do what you want (it doesn’t always). When I started out, now 47 years ago, I too was attracted to lost wax casting. Along with a lot of basic tools, I purchased a complete lost wax casting outfit. With the exception of the oven, it still sits unused in my shop along with a Hoover and Strong plating outfit. I have made a lot of jewelry since then. The only casting I do is with Delft clay. You can begin to get a feel for the basic casting process by working in Delft clay and you can buy kits for less than $100. You will still need some hand tools, some way to finish what you make and a torch. These are all things that you will need regardless of how you make jewelry. My brother and I both had the big advantage of a father to teach us the basics and tools to use until we bought our own. Try to find someone who will help you get started.

I did reach out to a few jewelers locally to help design the model, they just gave me a confused face and shook their head and that was just the model.

Since you spell jewelry with 2 l’s, you may not be in a place with these resources, but local community colleges sometimes offer courses and, if you have a rock and mineral club nearby, there may be people making jewelry with the stones that they cut and the inclination to help others get started.

Just recently I have located a local Silver smith where you can join in and at least watch them work. By the way you are right I’m from Norway so my language will have some glitches here and there

Stick with it, look for help where you can find it, but don’t be shy. Ask whatever questions you have and people will try to answer them.

The craziest thing is that my current plan is to produce one ring, of course if it is successful, I may or may not continue if there is a sufficient market here.

Good luck…Rob

Thanks a lot, I probably need it

Regards Per-Ove

-)

-)