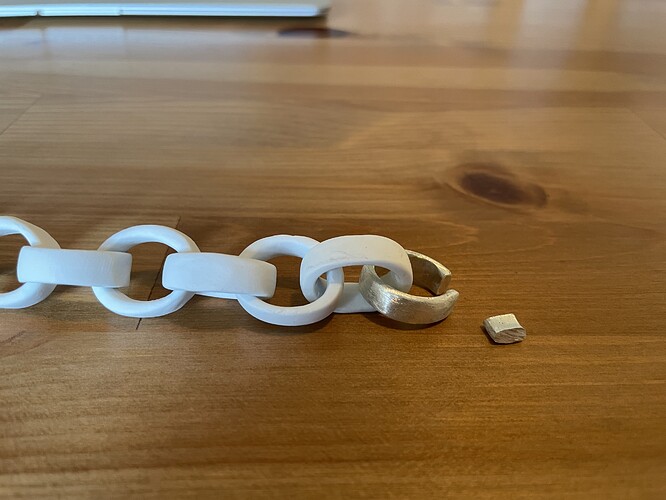

Hi all! I have this ceramics chain made my a client that they want me to make into a necklace. I’ve carved and casted a chain link in silver as in the photo. My question is whether I can solder the missing piece back onto the chain link without damaging the ceramics? It is unglazed which makes a difference I think. Will it break or discolour due to the heat? Does anyone have experience or ideas on this? Thank you so much in advance!

The short answer is that it’s probably not safe to solder so close to ceramic material. The easiest fix is to use a laser welder or a pulse arc welder like a PUK or an Orion. At this point many jewelry stores have laser welders who could weld this ring shut for you.

You might be able to submerge the ceramic in a tin can (or similar) with water, or some kind of commercial soldering heat sink material, exposing only the jump ring and solder it then. That’s a fairly thick jump ring that is fairly close to the ceramic material. You’d probably have to try it to know whether that would work or not. The good news is that you’ll probably only wreck one or two links if it doesn’t work, not the whole chain.

If it were me, I’d take it to a jewelry store with a laser welder. Like I said this is an easy thing to do with a laser welder or a pulse arc welder.

Maybe others have different suggestions, but from the picture that looks like your options to me.

Hope that helps!!

Jeff

I think Jeff has the best answer, but another solution would be to look into a cold connection like a rivet. Since you are changing materials, you could quite easily make the case to do a small design change with the metal. If you want to keep the similar form then Jeff’s ideas are the best in my opinion.

An easy cold connection solution are silver split rings. They’re the size of jump rings, but are the same style as key chain rings. I know that Rio Grande sells them. They’re a very different look though.

You can buy or make a lot of different industrial style connectors for jewelry. Do a search on “sterling silver clevis”…Rob

If you have a Little torch or similar oxygen-gas torch you can probably get a local enough heat not to damage the ceramic. Also for future applications, just cut the link in one place and bend it open/close to make soldering it easier (only one seam). If it is for decorative purposes you could even leave the closed joint unsoldered.

Thank you all so much for your replies! I’ve casted the ring again and will try cutting it straight down the middle and joining the two sides with a rivet type connection, leaving them unsoldered. The metal is so thick so opening/closing at only one seam is extremely difficult… Other chain links could work but the idea is for the design to be the same as the ceramic links.

I might also just try soldering, my client said she doesn’t mind if one of the links break but of course I would still like to avoid it.