Hello I am looking for some advice/assistance. I have the opportunity here in the next couple months to get “re-set” up better, and more efficiently. Although I have strictly done hand fabrication for the past couple years . I would like to prepare for the possibilities(s) down the road to increase my technique’s, equipment, knowledge and tools. At the moment I have been using my standard jewelers bench and tools, a soldering station that is set up horribly,. A polishing station that is set up directly next to my metal forging/shaping area, hole punch , dapping station, books-learning reading material, ultrasonic and cleaning area… “All of this is set up on the same dual level bench smashed together to make what I have been able to do possible. (UGLY, Cross contamination Yuck) There was barely enough room to squeeze into the jewelry studio and get into and in between my soldering station, bench, polishing station, etc…!) YIKES. I also use an ancient 40+ year old Guesswein G-70 rolling mill that I found from a retired jeweler that I will never be able to find replacement parts for… that I had drilled and attached to my kitchen countertop, haha

If you have the desire to make something happen, then you make it happen. So for the past couple of years that is what I have done.

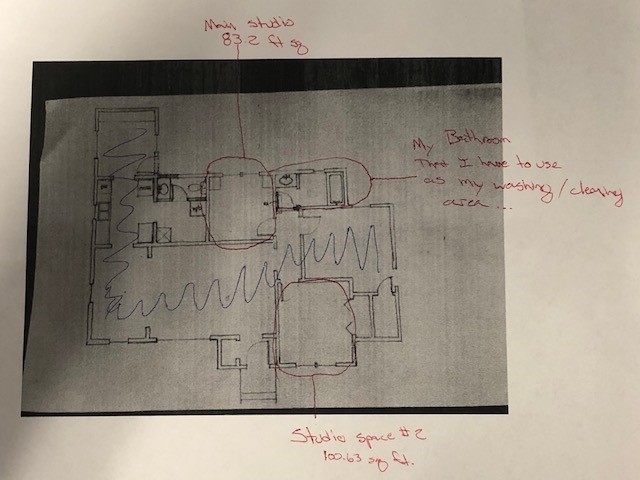

But Now I am putting myself into a position where I have cleared everything out of my current studio room as well as the “new(ish)” secondary potential work room/area. I am desperately looking for any advice on a more professional/efficient jewelry studio layout, blueprint, etc.

I live in Boise ID and although I have spoken with many local jewelry stores and jewelers, I have not received the warmest of greetings and or offers for assistance from these local avenues. I get it, we all work hard at what we do. We don’t want somebody coming in to our craft and saying “I want to know everything, give me all of your trade secrets now…”. But that is not me. I began smithing myself due to watching some good friends of mine who are amazing artists (and I got the bug:). I then took a couple classes in community college in OR. When I moved to Boise I set up a room in my home into my jewelry studio. After that I moved back to OR to attend and graduate from the American Jewelers Institute. Worked in my disaster area for a couple of years. I am an old man who got a late start, but really, Who Cares… Now I am just trying to get set up for many more years in this fun, challenging, awesome jewelry metalsmithing industry.

Here is the dimensional area of what I have to have to work with. I at the least need to get a proper soldering station area set up. Obviously my bench/flex shaft/tools area. Dapping and forging (metal pounding) area. Rolling mill with stand (and plenty of room to use it),area. Polishing machine, final polish steam area. Ultrasonic /cleaning area. Books, learning materials, drafting drawing area.

Main studio room #1= 112” wide. 107” long. 96” tall. So sq. footage of room= 83.22ft. squared

Secondary studio room #2= Second room 115” wide. 126” long. 97” tall. So sq. footage of room= 100.63ft squared

If you have any advice, ideas, or have been in the same position yourself and remember what it what it was like to want/need to improve your working area, but just not be sure where or how to start please don’t hesitate to get ahold of me. Any advise will be greatly appreciated. Also If you live here in Boise ID and would be able to come physically view the space(s) to get a hands on view of what I am trying to work with, that could be awesome. Here is my contact info

Jason Sheehan

JMS Designs

lowskeet@gmail.com

IG: jmsdesignsco

If you took the time to read all of this, thank you so much simply for that. I appreciate your time.

Hopefully one day I can move onto expanding my equipment and skillset. (I.E. wax work, jewelers bench improvement, magnification machine, grs systems, generator, casting equipment-kiln- centrifuge/vacuum casting, burnout, lazerwelder, etc…) lifetimes of things to learn and lots of specialized classes and techniques and hours/years of practice to get there…