I was thinking about making a jewelers bench out of steel square tubing and butcher block surface, kind of like this image, but a jewelers bench.

I was hoping to have shelves and such, and also a place to mount a rolling mill and gas tanks.

Does anyone have any ideas? Would love to hear them. My brain is dead when it comes to imagination.

Some suggestions.

Some kind of catch tray to catch stones and filings. Also, it’s helpful to have a ridge (even just an inch high) on the outside edges to keep tools, stones and parts from rolling off to the floor. Most jeweler’s benches have a ridges on the outside edges.

You have an L-shaped design which I think is great for efficiency of movement. I’d design it so I could swing my chair back and forth without having to stand.

There’s no drawers. You mention shelves. Are you planning to put all of your tools, metal, findings and stones on shelves? Otherwise you may want to consider some kind of drawer system.

It looks like it’s solid! Let’s see what other say.

Have fun putting it together!

Jeff

I have used a 4 foot long piece of bowling alley as my main soldering and forging bench for over 50 years. It has served me well. You can see pictures on my website of all of my benches. I have the luxury of a lot of room and I have managed to fill it up. The bench that you have should work, at least for soldering and assembly, I am not sure if it is sturdy enough for forging. I long ago moved my anvil to a stand alone pedestal. You might also consider ways to raise it if necessary. As mentioned by Jeff, figure out a way to add a catch tray. I just screwed a regular set of drawer slides under my bench and attached an old catch tray. Add a bench pin and a way to hang your torch and you should be good to go. There is a separate part of orchid that shows how others have configured their benches. There is also a good book The Jewelers Bench Book by Charles Lewton-Brain that has a lot of good ideas. The next challenge will be how to store all of your hand tools in a way that keeps them off your bench, but near enough so that you can get them when you need them. Finally, consider where to install your flex shaft and polishing equipment. You will need a way to collect all of the polishing duff and grinding swarf that you create so that it isn’t flying around your shop and into your lungs. Finally, think about how you will light your work areas. I have 10 four foot LED shop lights in my shop and several LED spots. You can never have enough light. Good luck and show us what you come up with…Rob

Hi,

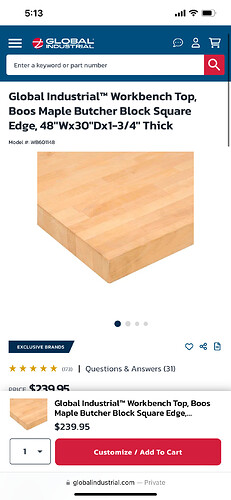

Global Industrial is a great resource.

they have benchtops in a wide selection of materials and sizes (i prefer a 4ft length bench and they can be hard to find)

they also sell the legs separately

as well as th4e benches complete

they also have alot of shelving/ bin/ rack solutions.

another also…i highly recommend considering vertical storage shelving at the back of your bench…this frees up the back of your benchtop, and adds easy to reach storage…

Julie

I think I have the rest of the bowling alley that Rob mentioned. It was Dad’s bench for many years and then many years ago it became mine. While it is an old bowling alley and there for probably maple I think a two inch slab of pine would do as well. What seems important to me is the mass of the bench top soaks up vibrations and hammer blows much as an anvil stump may do but to a lesser degree. I also have a drawer under my bench top that behaves much like the “Sink Drawer” in most kitchens. It catches most of everything and when you can’t find what you are looking for it’s probably in the “Sink Drawer”. The room has several LED lights and one goose neck spot over the center of the bench.

My original shop in the house we live in was originally a part of the mudroom and it was about 5’ by 7’. After 20 years we added a small addition and now my shop is 9’6" x 9’6". I have a small sink and a fair amount of storage. The most valuable space I have appears to be flat surfaces to collect clutter. Rob’s shop is neat, mine isn’t. Perhaps the most useful device in my shop is a 22" by 52" rolling cart that moves about when I need to use the shear, rolling mill, hydraulic press, ring stretcher and bender. I rotate the cart to access the needed tools. In a tight alcove is my polisher with ventilating fan.

There is also a guitar. I don’t know what I would do without such luxury.

Besides the obvious tools, ventilation and light are the most important components I can think of for a shop of this size.

Don

Oak stair steps can be inexpensive and they are sturdy. I used a couple of them for the top of a bench and they have not disappointed. I do wonder if you’d need to secure the bench to a wall in order to support a rolling mill.

I have seen pictures of a separate, small, study wall mounted surface with a rolling mill on top of it. As long as it is secured and can take the turning forces, it would be a good way to mount a rolling mill when bench space is an issue…Rob

Hi

i have 2 benches using these components…sturdy

(Boos make high end cutting boards too haha!)

julie

Hi,

also consider bench height…

i have heard that the bench pin should be…mid sternum height(?)

the global industrial benches i posted above have legs that adjust from 29” to 35”, and the top is 1-3/4” thick…so 36-3/4” height (i use them at 31”, for various things thst do not include a bench pin

my jewelers benches with bench pins have heights of 35-1/2” and 38” (i am shorter and prefer the lower 35-1/2…i have the legs on a piece of 1/2” thick wood strip)

a tip i found useful:

sit on your chair

feet flat on the floor

measure from floor to mid sternum

that height would be a good jewelers bench bench pin height position

also, some opinions are that chairs without wheels result in less stress to your core muscles…whereas with wheels ones core is more activated when working (to keep chair stable)…

julie

Hello Michael,

I have an “L” desk. One area is for the PC, the center holds the printer, and the other area is for everything else. Very efficient use of space.

Using a similar design for a jeweler’s bench is an intriguing idea. You could set up one end for the torch, put stacked storage in the center, and set up the other end for hand work/setting/hammering… For sure, you will want drawers and racks close to hand. I use those plastic chests of drawers on wheels that will roll under the desk if space is at a premium. (Iris minichest, Sterelite are two brands) Some of these can be stacked. As long as you are thoughtful about weight, these roll nicely.

I can envision shelves over the bench holding the little drawer cabinets like those used to hold screws, nails, etc. You would have to stand up to access such storage, but plan to use the vertical space.

Lighting is so important. The LED shop lights are great and some plug in, so hard wiring for outlets is the only necessity. A little research will give you ideas. Wandering around the hardware store is a fun research trip. You can never have too many electrical outlets, so plan for that. While power strips may be useful, avoid their use. Anything that draws a lot of current (buffer, Oxy concentrator, etc.) should plug into a wall outlet.

So many considerations. It’s exciting! Visit some jewelers and see their working spaces. Learn lots and make beautiful things,

Judy in Kansas, where temps are dropping - Fall is near!

Hi,

i am not sure if i already posted a pic in a past thread…

here is a pic of my metals/ fabrication bench, where i built vertical shelving above the back…i highly recommend vertical shelving!

this bench is very small…32” wide, 20” deep, and only 35-1/2” tall…(i do like that most of the front face is “closed” with drawers, and 2 sweeps drawers that keep it dust free

but on the flip side it lacks the typical open interior space to put hand tools while working…

i have 4 different benches, designated for specific activities, in a very tiny room…space is at a premium, and vertical storage is critical to my sanity…i work in organized clutter…i like “containment” options…haha!

being only 20” deep, i can easily reach my bur boxes on the lower shelf (10” above my bench surface) and the middle shelf (20” above my bench surface) from a seated position, and and the shelves “lift” everything off and above the small bench surface, which is very small

i had to leave a space for my Dazor light arm to pull down

i also have a cube unit on wheels, from ikea that acts as a “return” on the side of my bench and provides much needed additional surface area…it rolls in and out…if i had more room i would have 3 more!…i highly recommend!