Hi Everybody.

I’m trying to figure out if this gold wire is fused onto the sterling or just soldered .

I’d love to know which way to go about making a similar ring

Stephen

Hi Everybody.

I’m trying to figure out if this gold wire is fused onto the sterling or just soldered .

I’d love to know which way to go about making a similar ring

Stephen

I imagine it’s soldered with 14K yellow solder, likely medium or hard. There seems to be a visible solder seam along the edge. Much easier to solder gold to silver with gold solder than with silver solder. Fusing is a little more imprecise, more of a controlled melt.

Thank you so much for responding, , would I just use paper clips all the way around to hold the gold wire onto the shank and then solder?

What do you think?

Stephen

There is more than one way to do everything, so I hope you get other methods suggested.

I’d cut the groove using a graver or ball bur that matches the diameter of the gold wire. Anneal then bend the end of the wire to follow about 25% of the circumference of the ring in the groove. Hold the wire freehand or use a third hand and solder the first 8mm or so to the ring (after coating with boric acid and alcohol). While soldering you can usually pull down on the wire to seat it in the groove as you work your way around and solder as you go. If not, stop and clean it then bend and fit the wire in place. When you’ve got 25% left to go, cut it to length, push into the groove and solder.

You can try to make a complete ring of wire and snap it into the groove and clamp with spring tweeers. But it’s hard to avoid a spot or two that’s not down flush in your groove. I find it easier to do as I described. I do it this way when repairing worn channels as well, if not using the laser.

Mark

Which is exactly why I switched to Argentium. No soldering. Fuse baby, fuse.

Karen Christians

Western Avenue Studio, #506

122 Western Ave.

Lowell, MA 01851

781-367-4992

Pretty tight fit for a solder job, easier to make gold undersize and stretch ever so slightly till it’s a press fit & sweat together.

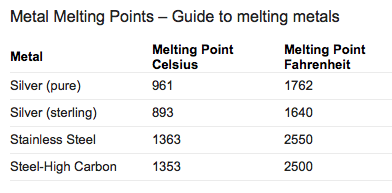

I’ve enclosed some melt temp charts if it helps at all.

Best,

Jim

I occasionally solder 18K to sterling. I’ve found that medium silver solder works best. That seems to be the consensus of the jewelers that I know. My understanding is that it’s the solder alloys reacting with both metals. They combine to what I believe is called a eutectic alloy. Similar to fine silver and pure copper - both metals have a higher melting temperature than sterling silver but combined the melting temperature is lower.

BTW - don’t get the piece too hot or the gold, sterling and solder will just “merge” - melt together.