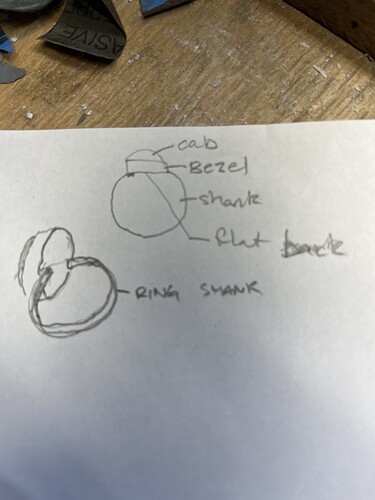

Hey gang, I’m trying to make sure I’m doing something right that I have been doing. When you are making a ring and you are bringing it to its final size, how do you measure the size if it has a flat back?

I have included a picture of a little sketch to illustrate what I’m talking about. Do I use the flat part of the ring mandrel to allow the ring as much contact with the mandrel as possible or do I put the round part of the mandrel up against the flat, back part of the bezel construction?

1 Like

Try it on and if it fits, you are good to go. Otherwise, if it is a plain shank like your picture shows, you are better off having it be a bit small. You can always make it bigger a lot easier than it is to make it smaller. My guess is that the flat of the mandrel to the flat of the bezel back will do this for you. My preference is to make the ring only first and then make sure it fits. Then file a flat over the seam and solder the bezel to the flat. This way you hide the ring seam, the ring remains round and there is only one solder joint to clean up. I also have the person who will be wearing the ring try on ring sizers until you find one that works. Run this up you mandrel (I have a round one with no size marks on it), until it is snug and then mark both sides of the ring on the mandrel with a sharpie. This way you avoid the problem of a size 6 ring gauge not being a size 6 on the sized mandrel. In my experience, this can often be the case. Except for my wife, I quit making rings a long time ago. They are a PITA…Rob

1 Like

Hi,

you could use a grooved ring mandrel…there is a flat spot…

consider getting a set that is calibrated to your ring sizers…so everything matches…

julie

3 Likes