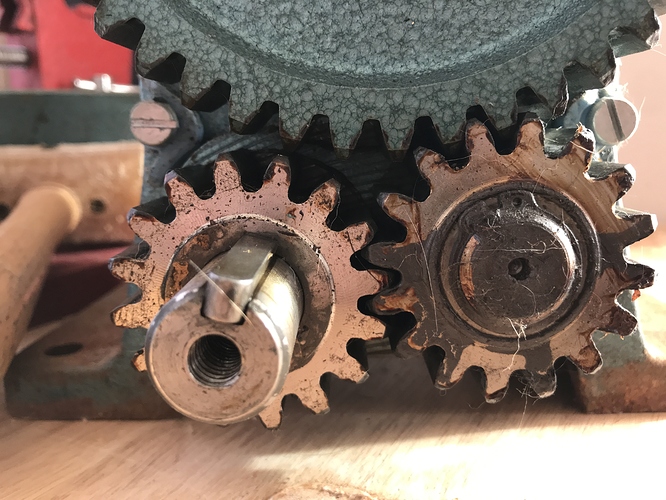

I have an old Gesswein G-70 combo mill that was water damaged, so I bought replacement rollers from Gesswein. Unfortunately they came without any instructions, and customer service said that since it’s discontinued, they have no directions available. I have removed the handle and the tiny c clamps holding the main gear, but it is really not budging and I wasn’t sure if there’s more than meets the eye, or if I just need to brute force it. Pics:

A word of warning! the main gear wheel will be made from either cast iron or steel.

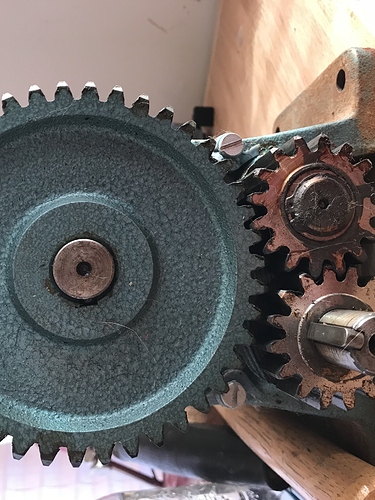

to remove you need a puller. if its cast iron the risk of breaking this gear is great, and it would then be a total loss to you. So you need the help of a small engineering co, that has pullers, circlip pliers etc. From the picture it looks as tho this gear is secured on the roll shaft with a std key. You may also need to heat the gear to expand it. also wd40 on the shaft. Easing fluid.

Look at the replacement roll it will have the corresponding recess for a key.

Its an easy job for me, as I have all that kit.

It depends on where you are. your going to need to put it in the back of your car/truck what ever and drive around to ask who has these tools.

To check what the gear is made of you need to file one of the teeth. Cast iron is dull gray, steel is muck lighter.

Get it right!.

however, just a thought, get some 3 mm lead sheet and put through the corroded rolls. you could have an interesting texture.

reminds me of the Japanese smith who hammered silver into a beach granite boulder to pattern his metal.

Ted in ~

Dorset UK.

I would let wd40 soak in real good on the gears. you have to take off the

snap rings in order to get the gears off. there is a special plier for

that. Good luck Vince Larochelle

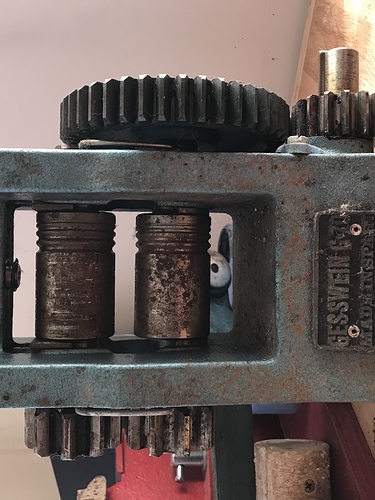

rollers as far apart as possible, which means

raising the top one as high as it can go.

There are brass pillow blocks the roller sits

on on the bottom and one on the top of the

shaft of the top roller.

What I remember is having to lift the top

roller up as high as I could ft it to go, and

then I could lift the bottom roller up

and remove it with the gear on it.

Don’t have that mill anymore so I

cannot check it to see.

Ted,

I removed my rollers without taking the

gear off, the other side just sits in a bronze

pillow block bearing.

Shaft on either side of the roller fits into the

bronze bearing and only allows it to move

up and down, springs on the top of the

bearing blocks hold the blocks in place, and

allow the top roller to move up and down.

Hi Richard,

Yes I followed what you say, however the bottom roll has the large gear keyed to it, so it might come out of the mill frame it might not.

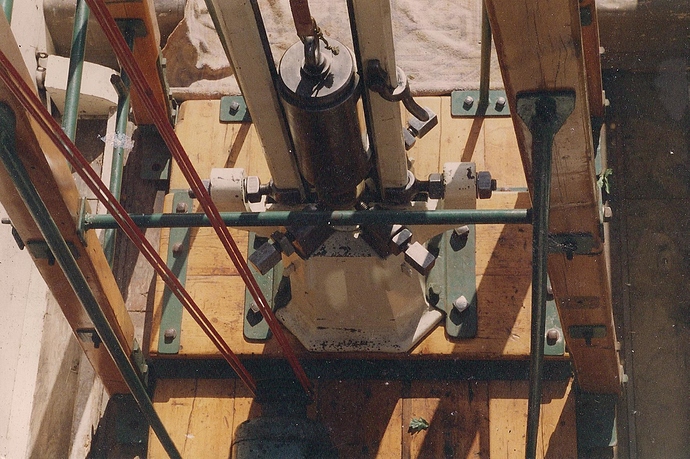

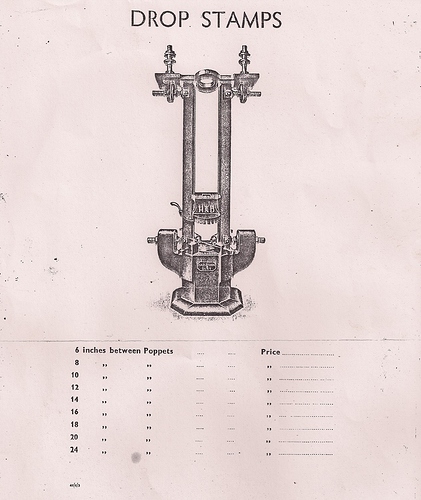

It will still need this large gear removing and putting back on the new roll. My humble experience as an engineer of a few yrs standing, old neglected machine parts especially if water damaged will be seized on pretty firmly, and its unlikely that Gina will have the resources to do this exchange. As an aside, most of my machines are old or VERY old! and have always needed to be rebuilt. The drop stamps in particular. Heres a pic of the medium one .

All I had to start with was the 4 rusty castings salvaged from a defunct jewelley business in B’ham UK.

I had to make my own hammers. This one is 275lbs.

enjoy.

Ted…

I already found some circlip pliers, so that’s not a problem. Will check around for gear pullers, I may end up buying some. Here’s a pic of the new replacement rollers, not sure what you mean by a standard key?

Thanks Richard, the gears will also need to come off, to go on the replacement rollers. Your insight did get me further along though, I think between you and Ted I may get this working! One other question, how do you get that aluminum wire clip thing off the rollers? Pics below to show what I am talking about: