Hello everyone! I’m brand new to the community and I was hoping to start my journey here by asking a question. I have been making pendants and rings with wax, for lost wax casting. I really want to try casting stones in place, but I cannot figure out how to make beads from the wax. The trouble I keep running into is that I can only seem to produce wax drips that are much too large to be a reasonable bead. In most cases my attempts to make a bead result in completely covering the stone I’m trying to set.

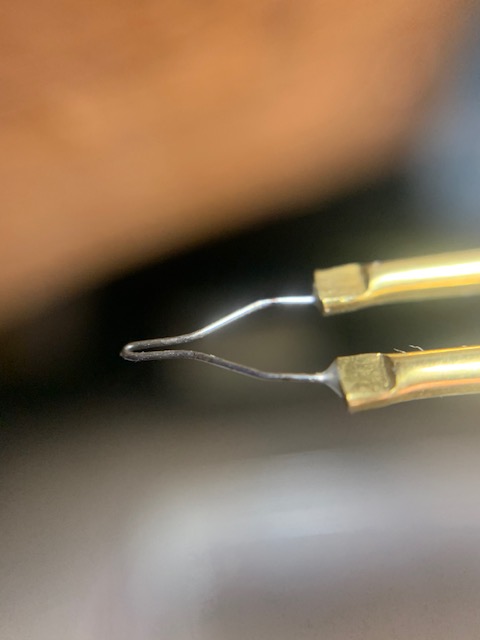

The tools I’ve tried are an array of dental picks, large and small sewing needles embedded in a wooden handle, an adjustable temperature soldering iron, and battery powered max wax pen. The best I’ve been able to accomplish so far has been with the dental tools, heated over an alcohol lamp. I scrape a bit of wax onto the tool, heat it over the lamp until it’s liquid and then hold the tool with the point down until the wax beads up on the tip.

This hasn’t been entirely successful because it takes much too wax for the bead to actually come off of the tool. At the point where gravity takes over, the amount of wax will make a droplet that is several millimeters wide. Without that much, the wax just pools up very near the tip, but never close enough for me to deposit it onto the model.

Does anyone have a method they can describe for me? Do I absolutely need one of those expensive waxing pens? I’m not entirely opposed, especially if it will reliably get the job done. I was just hoping to avoid the cost if I could. Thanks and I look forward to being a part of community moving forward!