Hello there, this is my first post here. English is not my native language, so I apologize for any mistake I could make.

I started jewelry two years ago, at first I was doing some wire wrapping with recycled paperclips and electric cables, then i discovered that jewelry was a great job, involving more different techniques than any other job. Then I learned using a flex shaft with the cheapest one i could find, then I got interested in soldering, then i wanted to get better colors on copper, so i had to learn about chemistry, since there’s no commercial product available for jewelers where I live. Then i wanted to learn more about chasing and repoussé. Made a dozen of punches and stamps out of nails, but that was too small, so i made twenty more out of grade 8 bolts. Getting to this point, i had to learn more about steel, I had to build a forge, find a good anvil (a train rail), etc… But i had no money. That was the funniest part, I think, since I had to make almost every tool or chemical, without any knowledge. Internet helped a lot, of course, and so did Ganoksin.

So now, after i’m getting to the point where i want to learn more about hand-pushed engraving. (and eventually, hammer and chisel).

As always, I could not find any graver where I live, and since i don’t know if I want to spend money on tools i could make myself, I bought some piano wire for the blade, found an old brass pin vise and a door handle in the garbage out there, and made this. Less than 1$. One hour. Works great, now i want to learn everything about hand engraving ! (Will have to make a good engraving vise first. This is so hard and dangerous to do holding the metal with the other hand.)

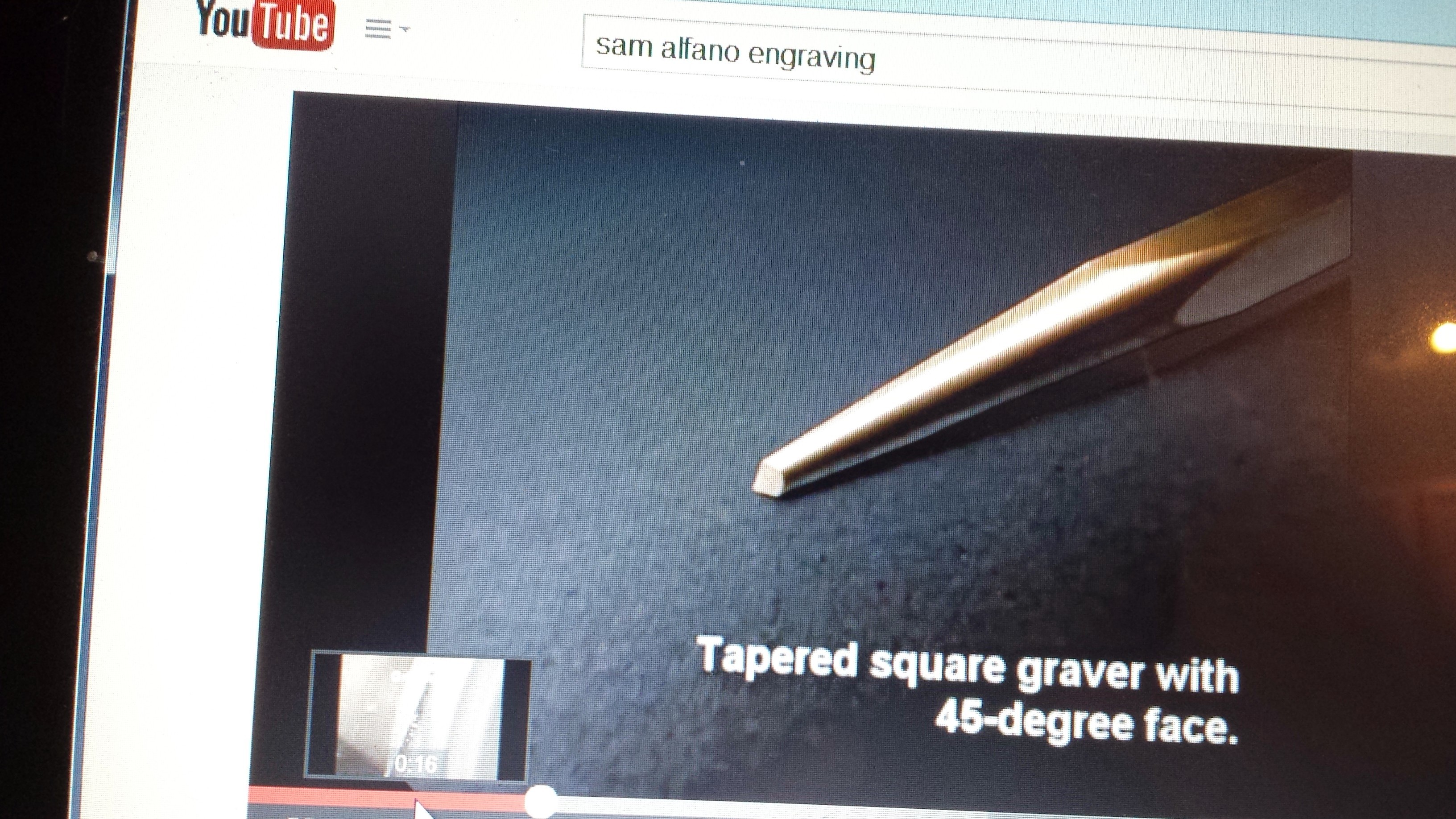

The piano wire is formed to an onglet shape, then quenched and tempered to hold a sharp edge. I might have to make a wider onglet, this one looks more like a knife. Cuts pretty well into mild steel, aluminium and copper. Cuts fingers, too…

I don’t know if it will retain its cutting edge for a very long time, but I can sharpen it every so often, A whole day of practice and thousands of cuts has not altered it in any way, so i guess it’s gonna work. Masonry nails do a poor job, compared to this steel.

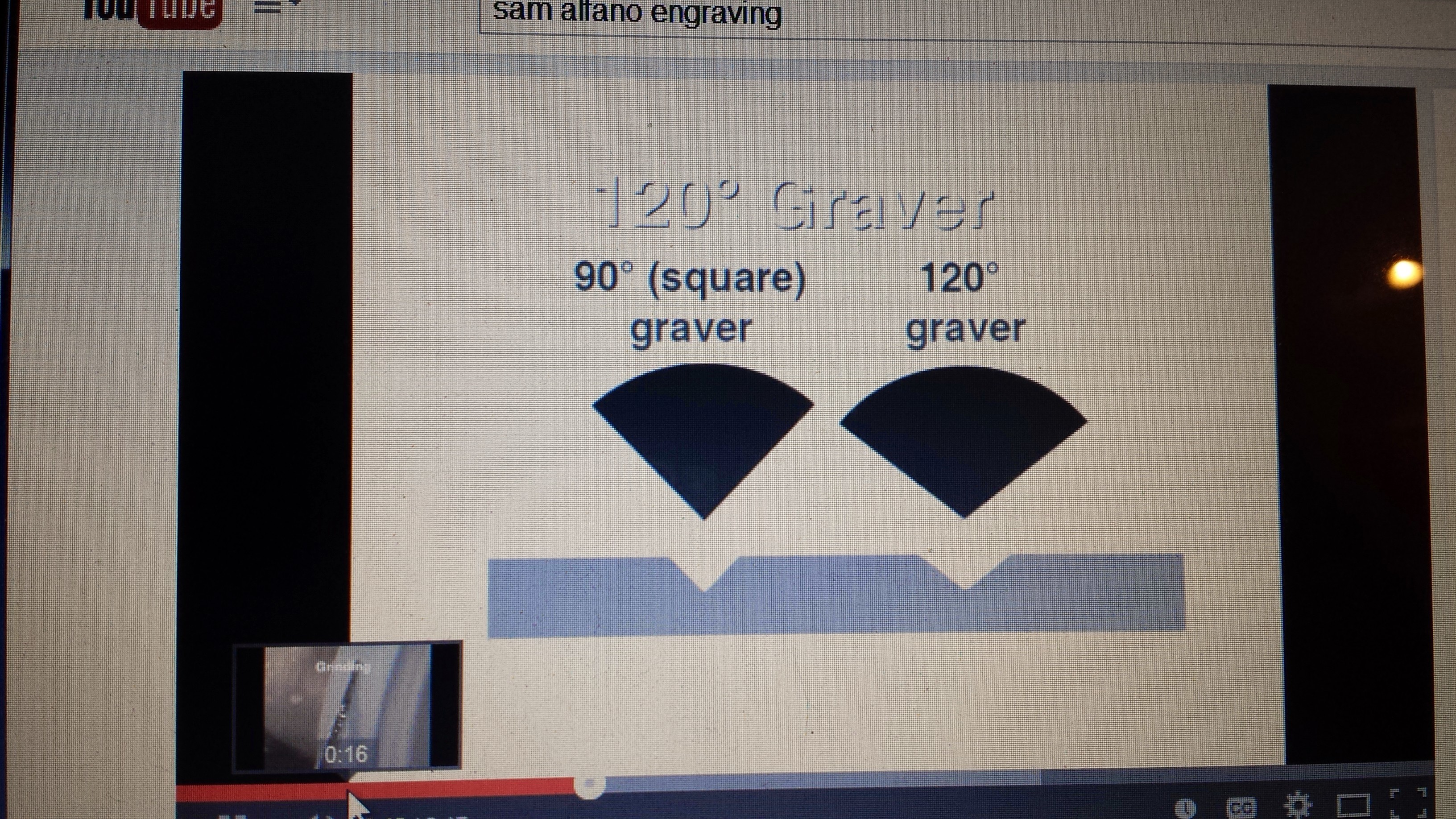

Any advice on what kind of graver shapes I should practice with first ? Anyone has used piano wire to make gravers before ?

Thanks for everything.

Pierre.

!

! But hopefully i’ll overcome this difficulty soon enough.

But hopefully i’ll overcome this difficulty soon enough.