Hi all,

In response to several requests, I have posted a couple photos of my

homemade bead loom on Orchid’s FTP page: the file names are

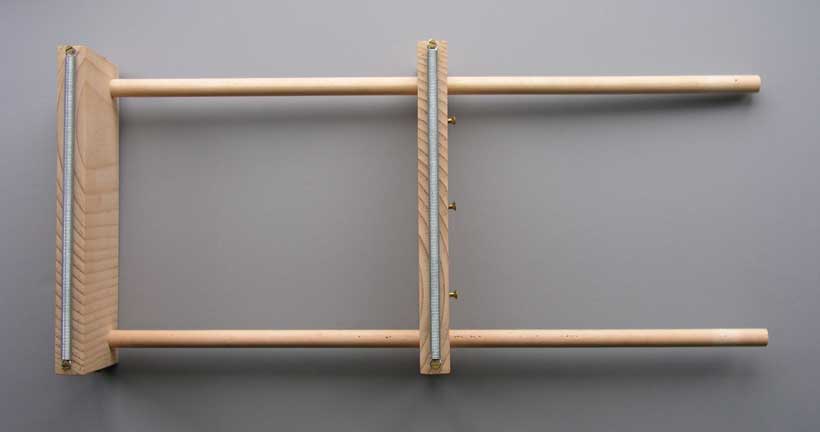

The first picture shows the loom assembled and ready to go, while the

second shows its constituent parts.

I remeasured the loom and found that the boards are about 8 1/2" x

3", the dowels are 1/2" diameter, and the springs are 8" long.=A0 The

dowels were originally straight, but seem to have gotten bowed with

use; this doesn’t interfere with the effectiveness of the loom.

I got my springs from beadcats.com, but they can be found at

hardware stores as well.=A0 The wire thickness of the springs is

about 18 ga., which makes them a good size for small beads (14/o

through 22/o) as well as larger ones; a thicker wire might only

accomodate larger beads, but with the smaller gaugewire, you can

space out the threads to fit varying sizes of beads. The screws

that hold the springs are spaced just far enough apart to have to

stretch the spring a little bit to pull it off, but not so far that

the spring is streched out during use.

As you can probably tell from the picture, especially the little

dents along the dowels, the screws that hold the dowels in place

aren’t driven all the way into the dowel, but just enough so that

they “bite” into the wood and keep it from moving.=A0 This has the

advantage of making the loom infinitely adjustable, and you can use

longer dowels for longer pieces of beadwork.

When stringing up the warp threads, tie the free end of the spool to

one of the screws and pass the thread between two of the coils of the

spring. Stretch the thread across the loom to the other side, pull

it between the coils of the spring on that side, loop the thread

around the screw to hold it in place, and bring the thread up and

pass it between the next pair of spring coils. Do the same on the

other side…and so on until you have the requisite number of warp

threads (one more than the number of beads that will make up the

width of your piece). For 14/o beads (the ones I use most

frequently), I string the warps in groups of three, skipping a space

of two coils between each group.

When the weaving is finished, I usually loosen the screws at one end

of the loom to relieve the tension on the warp threads, and then lift

off the springs one at a time and stretch them to release the threads

and remove the work from the loom. Sometimes a thread will

magically loop itself around the spring in a way that doesn’t seem

physically possible, but I allow enough length that I can just cut

the thread if need be.

If you’ve gotten used to the sort of bead loom that has a roller

attached to one end to take up the finished portion of long strips of

weaving, I think this could be easily made by cutting a length of

dowel to fit horizontally between the dowels at either side of the

end board, setting bolts with the heads removed into either end, and

drilling holes for the bolts horizontally through the lengthwise

dowels. The roller dowel could then be fixed in place and tightened

with a pair of wing nuts.

A disadvantage of the loom is that it rests flat on the work

surface, which can cause back and neck strain after a while. I

usually prop mine up witha copy of Gould’s The Structure of

Evolutionary Theory, which is heavy enoughnot to move while working

and a handy 3 1/2" thick or so. I have come up with some sketchy

ideas for a free-standing upright loom, and I’ll be happy to post pix

of that should it happen to work ![]()

For other diagrams, loom ideas, and instructions on beadweaving, I

(again) highly recommend Virginia Blakelock’s Those Bad Bad Beads.

It was from Blakelock’s book and the Beadcats store (which she

co-operates with Carol Perrenoud) that I got the idea for the bead

loom, and any credit for it should probably be theirs.

[Usual disclaimers]

Those bad, bad beads!

By Virginia L Blakelock

Manufacturer : V.L. Blakelock

Release data : 1988

Hope all this is helpful - happy beading!

Jessee Smith

www.silverspotstudio.com