In these three coloured photographs, you can see just how one single ‘High Speed Steel’, aka HSS bur can navigate around multiple claws with ease. The most desired is a 90 degree angle bur, not a ‘setting bur’ as these are two very different styles of bearing-cutting burs. As it is written (somewhere)

" Thou Shalt Not buy a 70 degree angle, Under-Cutting bur! " No where can you find a 70 degree angle gemstone, those 70 angle burs are available, but I wouldn’t buy one, so why would you?

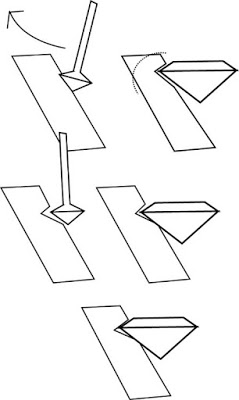

Furthermore, don’t buy the soft “156C” carbide with very shallow teeth for this style of engagement rings, as these burs have a very short shelf-life. The HSS burs ARE THE BEST there are. Their teeth will carve the metal more aggressively and now PLEASE notice how an incorrectly contoured bearing is made, shown in the bottom three pictures!!

The bur-shaft must be held at a 45-angle away from Centre. This is the correct positioning of the Pavillion facet as it will rest/sit! Please look at the ‘top row’ of diagrams, understand?

Also notice just where the “Culet” of stone is now resting, right in the very centre of the claws!

BTW, in my collection of HSS burs, I have approximately 136 burs all ready to carve bearings.