Hi,

I am a novice maker, but decided to take on an ambitious project of making an engagement ring for my girlfriend. 4-prong solitaire setting that would hold a 1 carat stone.

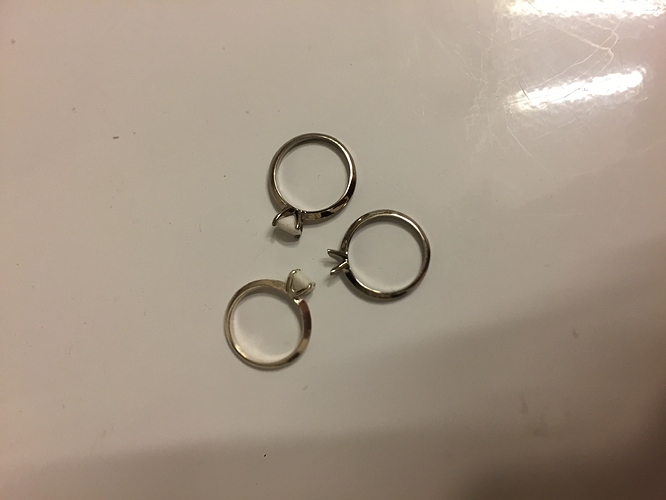

I started with making the ring shank out of silver. I tried to make the prongs as well, but it turned out to be too challenging at this point with not so much experience. Simply put, I was not happy, the few versions I did were not close to the quality I want to give to her.

So, I decided to model the prong part in 3D, print it in wax and cast in metal (used Shapeways for this). Then I soldered the parts together and finished the ring. I know professionals would never do that, but unfortunately I don’t have years of time to practice at the moment. Wish I had

Anyhow, I did the first versions of the ring from silver, and then tested them out by setting the stone. I actually had a model of the stone 3d printed in plastic, so that I could test stone setting safely. Silver versions worked fine, and I was able to gently bend the prongs over the “stone” nicely.

However, when I had the same design prongs printed in white gold, the prongs broke a bit below the tip when I was bending the tip over the stone. Well, I thought maybe the prongs were too thin and redesigned the prongs for the next version. Again, I had it printed out in white gold, and exactly the same occurred again, even though I had strenghtened them quite substantially. A few of these failures caused my proposal to be pushed back, and I had to pull the plug on my plans.

I am starting to think that the cast white gold from is too brittle for ring prongs, and I am having trouble deciding what to do next.

As experts, what do you recommend? Change alloy or something else? Or is my only option to just go down the long path and keep on practising prong-making from solid stuff until I get it how I want?