Hi!

Regarding heat treating O1 tool steel, i have a question regarding the process that i am hoping someone can help me with.

when heating:

-

i can get to a bright orange…should i be getting to bright red?

-

at bright orange, i test on a magnet and it “sort of” feels non-magnetic…

-

after re-heating to bright orange after testing, i quench/swirl in oil

-

at this point, when i re-test on magnet, it feels magnetic…should the non-magnetic nature remain?

-

i also test with s steel file, and it “sort of” sounds “glassy”

i tried hardening 3 times as above…the first two times, the tool was definitely still magnetic at bright orange…

the third time, i was also seeing bright pinpoints of color within the tool…is this significant?

the tool i was trying to harden was a quality stamp from Infinity Stamps…i wanted to anneal and taper tip for better visibility, and then re-harden and temper…

i am not sure if i hardened correctly…

any help would be greatly appreciated.

Julie

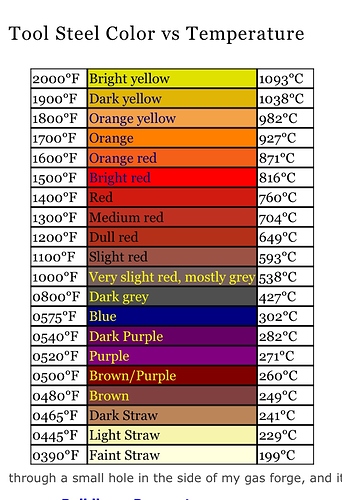

here is a link i found with a color chart by tempurature reference.

interesting…bright orange is hotter than bright red…

i need to look harder for the bright red before the bright orange…

on another note, i read somewhere else where too high heat causes issues…but it did say one issue is de- magnetization…so still not sure why i cannot get to de-magnetization, if in fact my problem is getting too hot…

i will call supplier and inquire what steel type tool is made of…perhaps it is high speed steel or something…

http://threeplanes.net/toolsteel.html

julie

So if you poke it with a magnet when it is at temp and you can’t pick it up it should be at the austenetic temp, somewhere between 1300 and 1400 probably but it depends on the amount of carbon. Then you can quench it and it should be hard. Now temper and you are all set.

Hi!

ok, thank you. maybe i “think” it is bright orange, when in reality it is only dull red or medium red and still below bright red…

will keep trying

julie

Hi,

ok! talked to infinity stamps…reason i was having a hard time is that their lovely stamps are M2 high speed tool steel… which require much higher temp…for hardening, as well as needing a few additional stages of preheat and 2 temperings…

so! i dont feel so confused about not being able to get it to de-magnetize at bright red/orange!

julie

ok! found the answer to the last part of my question!

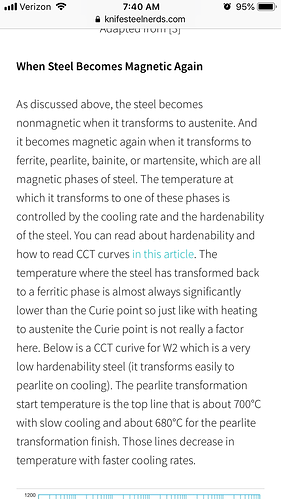

as steel turn to austenite- it becomes non- magnetic

when immediately quenched turns to martensite, which is magnetic, so it becomes magnetic again!

whew! i was wondering!

julie

hi,

sometimes answers take awhile to ferret out on google…gotta keep searching and reading and learning, to be able to keep refining search phrases in order to get more specific search results!

julie

hi,

and the answer to another of my questions is that the “sort of magnetic” feeling was not my imagination!

the steel transforms from magnetic to non magnetic, with lesser and lesser magnetism until it is totally not magnetic, when it reaches the austenite stage.

so, i was just not there yet…and would have never gotten there being that it was M2 high speed tool steel and requires higher heat than i was able to produce!

julie

On another note, if you draw the temper only on the tail end so you can taper it you don’t need to reharden it. It’s kinder to your hammer if it remains softer than the hammer face. It will mushroom a bit over time, but a quick touch up on a bench grinder will take care of that.

Hi Elliott!

good to know that!

i was trying to taper the working end, so that i could register the stamp on tiny strips of metal better, to make quality tags, to solder onto stuff i could not stamp directly.

julie

If you invest in a bench grinder, something every metal studio ought to have anyway, you can grind the hardened end without have to anneal it. You needn’t buy an expensive grinder, an inexpensive one from Home Depot or similar store will be fine for the occasional use it will get. You can even just get a grinding wheel with a lead center designed to thread onto the tapered spindle of a polishing motor. That would be the least expensive way to go.

Hi Elliott!

oy! i have a bench grinder!

julie