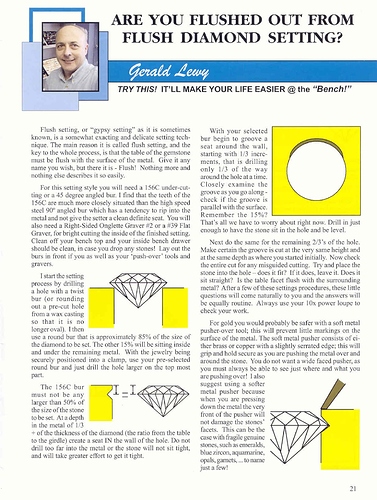

"Gypsy/Flush Setting" (including a “Bench” magazine article that I wrote, circa 2004. I was unable to ‘edit’ the magazine page advertisements.

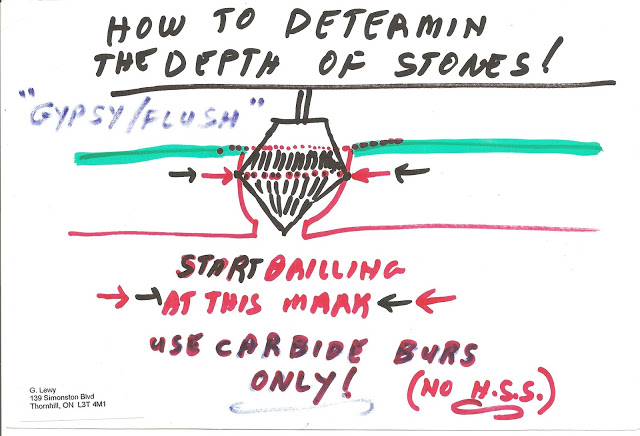

This essay will carefully explain the very important setting steps when you are hammering the metal in the “Gypsy/Flush” setting!

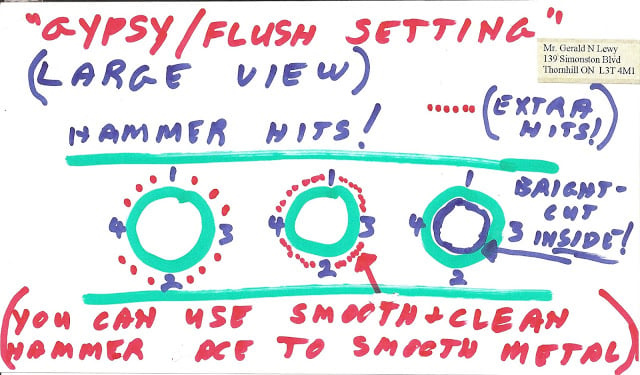

I intentionally ‘darkened’ the ring surface for one simple reason. That reason is that this is the only method for you to see where your hammer is actually touching the surface of the ring.

This is the angle of the hammer (45 degrees) while it is making direct contact. The hammer must never touch the “edge of the (stone) hole, or opening”.

Your hammer is basically doing two things, that is to 1) ‘Move’ the metal towards & 2) Over the edge of the stone, nothing else!!

In this picture, you can see just where the multiple (8) ‘hits’ are taking place. The next step is to hit ‘gently’ all around the frame of the edge of the stone, nowhere else!

Your Pumice wheel is your very ‘best friend’ in all kinds of stone settings. It is now removing every ‘hammer hit’ that you might have made on this soft .925 silver metal setting!

Can you see just how close to the edge of the hole the side of the Pumice wheel is going? Getting closer with your wheel and it is then waiting for the ‘damage’ to start!.. ;>(

Just one touch of your rotating Pumice Wheel and your stone will lose many of its "Upper-Girdle" facets and including the ‘Table facet’ surface. There is just no quick method to repair the stone, except removing it and messing up your ring. A.K.A … YUK!

==============================

In this (not on this topic) photograph, but worthwhile to mention, y ou can see that I went and engraved a pattern with my interesting graver, aptly named " Liner, 10/16".

I use my “Liner, 1016” to engrave a “###” pattern when and where needed. This pattern is aptly named a “Florentine Finish!”

I would use this innovative pattern only if the metal has multiple ‘casting errors’. The errors are if my item has numerous ‘pin-holes’, anywhere.

There are 4 pinholes in this pendant, can you see them?..:>)

I thought that this ‘little extra surprise finishing note’ would be interesting and helpful to you and everyone!