I’m building a custom opal ring in 14k. Does anyone have a recommendation on how to decide inn bezel thickness, ring shank thickness? I want to make money obviously but I also want the customer to be delighted at the gold weight of the piece. Any insight would be helpful!

Also, I’m dealing with a lot of fatigue at the moment so if my question needs more context or info please let me know!

Opals are fragile, so think about how you will be moving the bezel to keep from damaging the stone. You might also consider an open back. Otherwise, it is up to you. Personally, I like to see opals in a simple light settings made from yellow gold with an emphasis on the opal, but I am a mechanic not a designer. Good luck…Rob

I’m not sure how to comment on the ring shank? It really depends on the design. For the bezel though remember that 14 kt bezel doesn’t bend over easily, especially compared to fine silver. 28 ga is a common thickness.

A lot of times I’ll end up hammering a gold bezel to get it flush against a stone with either a hammer and punch or a hammer hand piece.

I know that opals crack easily, but once you’ve had enough practice, hammering a bezel is often safer that pushing it with a bezel pusher.

No matter what setting technique that you use, you’ve got to be careful!

What is the size and shape of the opal and finger size? That also affects the answer to your question.

Jeff

Hi,

would a 22k bezel strip work…?…they are pretty…

bezel shank…1.5 at the bottom…1.8-2.0 at the sides…?

julie

Definitely. This is a ring that serves to celebrate the natural beauty of the stone.

Thank you @jeffg-moderator thos very helpful. I was oscillating between .3 and .5 mm bezel thickness. But your comment about the natural toughness(compared to silver) helps inform that decision.

Always appreciate you.

I would LOVE to do 22k but this ring won’t be the one. That size shank is very close to what I was thinking as well. Thank you so much.

I got blindsided on my first 14kt setting so I just want to emphasize what Rob said. 14kt is surprisingly hard. I have some earrings I’m working on and the setting works fine with silver but is impossible with 14kt. The entire earring folded up when I tried to push it over and I had to re-design the piece.

Jeff mentioned that gold is harder to move than silver, that is why I suggested that you take this into account when you design the bezel. Learn to use a hammer and punch or bezel pusher. I have moved up to 1.5 mm wide silver bezels this way and I know that others go much wider. Good luck…Rob

I’d always start with the ring finger size first, and work out from there. Then the center stone size. If I was carving a wax, I’d take into consideration shrinkage and finishing in determining the wax size. The ring size will determine how the lines flow into the top. In making the a ring directly from the metal, starting with the the correct ring and stone size is just as important.

When I was making custom rings, I’d try to make the sides of the ring approximately 1.5 mm ± up to just under 2mm, with the base of the ring 1.2 to 1.5 mm. These would be finished thicknesses. Having the thickness in these ranges will minimize the ring bending and will give a proper look and feel to the ring. Many of the commercial rings today are much thinner.

In designing for a center stone, and an opal specifically, one wants to isolate it from the affects on the shank of wearing the ring. In other words, ring shanks bend. Having the top too low and part of the flow of the metal, can cause undo stress to any stone, particularly an opal. Creating depth for the top of the mounting will create interest and set it apart from the movement of the metal of the ring when it’s being worn.

The thickness of the bezel is most important around the stone. If one use a thickness of 28 gauge for the whole bezel and attaches a ring shank to either side of that bezel, when the shank bends, that will cause undue stress to the center stone. But, if you use a much heavier and taller bezel, and attach it to the ring shank, it will better isolate the stone from the movement of the ring shank. The proper thickness can be cut into the bezel to set the opal.

Many smiths in designing their rings, tend to make them two dimensional, which in my opinion makes the rings less interesting, and can cause structural stress. A ring has three dimensions, why not use the added pallet.

Tjones

Goldsmith

How do you like going that wide with opals? No problem? Are you actually pushing it over the stone or just compressing it and it starts to deform sideways over the stone?

Hi Brennan,

are you planning on using bezel strip? or fabricating the bezel out of thick sheet or wire…and cutting a seat…?

how tall is the opal?

julie

Very nice work!..Rob

I appreciate everybody’s input on this. Just to be clear I have already made this ring many times in silver and also with a 14k bezel with silver shank so I’m not wondering how to make it so much as the pricing aspect but I do think that all of the advice given about all these different things is greatly helpful.

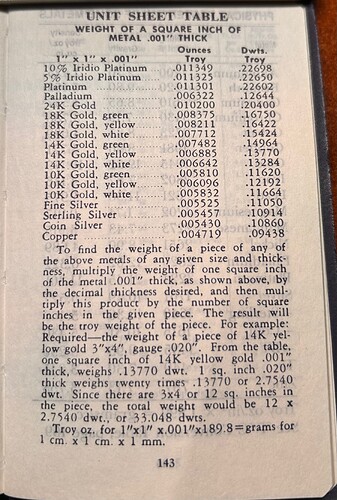

If you have already made the ring in silver, and you are looking for an estimate on what the gold weight would be ~ I’d take the weight of silver ring and multiply it times 1.4, this should give you a rough estimate.

Stuller is selling 14k yellow cast grain at approximately $80 a Dwts.

Here is a chart that can give a more exact estimate .

Thank you Rob

Tom