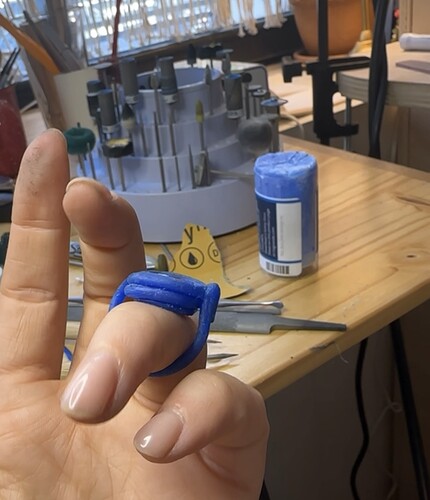

Hello all! This is my first post as I’m a newbie jeweler. I’ve mostly fallen in love with wax carving, but have a desire to make some spiral wax designs that none of the waxes I’ve used yet have been perfect for. I envision one fluid line wrapping around the stone; this has been my best attempt yet using wax wire however I hate the inability to get the wax smooth (is there a trick to this with wire?), and how easily it breaks/falls apart, especially after welding pieces together. It was a miracle I got this one to stay together long enough to actually put my finger through it!

I have thought about attempting to carve the shape out of hard wax, but that seems like much more work than necessary when there is an already round and wire shape wax available (albeit the worst consistency and workability). I have interest in the Matt wax gun, but haven’t pulled the trigger on the investment since I’m not exactly sure if it could execute what I’m aiming for.

If you have any tips or know of any other kind of wax I might be able to use to accomplish this, I would love to hear! Thank you all

Have you thought about making your model from metal clay? The design you shared would lend it itself neatly to metal clay. Check out what can be done using metal clay https://amcaw.org/superbly-sintered-2024/ https://amcaw.org/superbly-sintered/https://amcaw.org/learn/learning-center-resources/

1 Like

Thanks I appreciate it! Unfortunately I’m hoping to cast in 18k and I don’t believe there’s metal clay for that

I’d start with one large piece of hard green wax and sculpt it from that.

Hi,

another possibility would be to fabricate it in silver, and then use that as a master to make a rubber mold, then injection wax model, then cast in 18k…

there would be the extra step/ cost for the mold, but perhaps fabrication would give you the stability of structure to help perfect your design…

i can also see it being done in CAD…

julie

1 Like

Maybe I am not that skilled yet  but I’m going to try it next

but I’m going to try it next

1 Like

This is a great idea. I always forget you can use one metal as a model for eventually casting in an other metal. Thank you!

welcome, christine,

As far as waxes that might give you a more sculptured look, I would have to check my books as I don’t do that much with waxes now. There are several old books that would tell you about this stuff…if you have a good local library, they might have some of them…a lot of stuff is on openlibrary.org and you can borrow it on line. Lawrence Kallenberg’s book is a classic! I have no idea what-all is on Youtube, prolly a LOT.

I’ll check and report back. Where area are you located in, generally, Christine?

-royjohn

There’s a lot of great tips here! They’re also very diverse and cover a wide range of perspectives.

Some things that I’ll add.

There are zillions of YouTube videos about making wire rings and setting stones. One thing that is common to most of them though is that thinner wire is easier. 16-18 ga is on the thick end. 20-22 ga is most common. Of the perks of making a ring like this in wire (assuming that you don’t put in a bunch of dings in the wire with pliers) is that it’s easy to polish and to keep clean looking. A tip for pliers that put in fewer dings into bent wire is to get some round/flat combo pliers. Round goes on the inside of the curve. Flat goes on the outside of the curve. Plastic jaw pliers can be helpful as well.

I’d recommend watching some YouTube videos and play with different thickness of wire. You mentioned that you are a newbie. Learning to shape wire into a ring is a great skill to add to your technique tool kit.

At one point, some jewelry tool company came up with the idea of making wire shaped carving wax. I just tried to find it and it appears to have been discontinued. That would have been a great thing to play with. I mention this because, maybe it’s still out there and I just can’t find it.

If you do want to use the soft blue wire wax here’s a couple of tips. As you’ve learned it’s super brittle. To soften it before bending soak it in warm water. Warm water, not hot water. You want make it more malleable, not melt it. You’ll have to keep putting it back into warm water as the wax cools to keep it malleable.

There other thing is that because that kind of wax is so soft, it is a magnet for dust, metal filings and any kind of debris floating around your work area. This means that you and your work area must be obsessively clean. Clean hands, clean tools, clean work area. Clean everything.

This wax mandrel set used to be less expensive, but it’s awesome for forming wire wax. Put a tiny bit of oil on the mandrel to keep the wax from sticking to the mandrel.

Hope that helps a little!!

Jeff

3 Likes

Hi Jeff,

speaking of pliers and bending…i personally gravitate toward parallel pliers for bending thicker wire/ sheet…i found 2 pairs of stepped round/ flat parallel pliers that come in handy…especially if i need a smaller bend than my PePe ring bender can achieve (6mm inside diameter is the smallest size)…

julie

1 Like

Thank you so much! I will have to check out the library. I’ve searched high and low on YouTube but I don’t even really know how to describe it in search terms so maybe that is why I haven’t come up with a good enough tutorial. I’m (luckily) located in nyc!

This is fantastic info, thank you!! I will surely have to play with wire and the proper pliers; one of the reasons I have not gravitated toward fabricating in metal is because I want the twists to lay perfectly against each other, forming (mostly) one connected surface, so maybe this is an argument for carving from hard wax. I am definitely also going to play with the wire after heating in warm water, I haven’t tried that yet, and I am certainly not meticulously clean, so maybe that will help too

Do you have a pendent motor or foredom? There are nice wax carving bits that fit that too. So many fun ways !

I do! But I don’t have many bits specifically for wax (when I’m shopping for bits I don’t really know what’s what!), do you have any recommendations?

1 Like

We have a set from Rio. I think they’re like metal burs but the space is larger between cutting edges so they don’t load up with wax. Whatever you do, show the results!

Hmmmm now you’ve got me thinking about cutting a strip of blue carving wax and rounding it into a thin wire… I wonder how much I could curve it before it would snap!

It will be similar to regular low temp/low strength wire wax in that you’ll have to warm your carving wax to create the optimum flexibility. The temp will be higher. How much higher you’ll have to experiment to find out. I often tell students that they have to embrace the mindset of an inventor. That’s what you’re doing!

Let us know how it works!

Jeff

I wouldnt spend your money on the wax gun. I tried it a few times but the amount of wax that was extruded was small and layers dont stick to each other and you wind up with “strings” when you move around. Just like glue guns

Better to stick with carving wax and other traditional wax options.

Good luck with your project

1 Like

I saw an instagram ad today for this class and thought of this post! https://www.waxcarvers.com/class/soft-wax-bezel-settings/

I have not taken this class- I generally prefer hard wax myself. But looks like they explain what you want to do.

1 Like

I make rings from wax wire and I find the blue wax wire is very soft and fragile. You are better using sprue wire - it comes in a variety of widths suitable for rings and is not as fragile but still malleable and easy to shape. The ones I get are pink or yellow - it may be different where you are.

3 Likes