I recently acquired a new Foredom P-DP30 drill press so I could use my Foredom flex shaft in more ways. I comes with an adjustable table to place smaller items or that could be removed. There is a center hole and X shaped linear openings with the hole in the center.

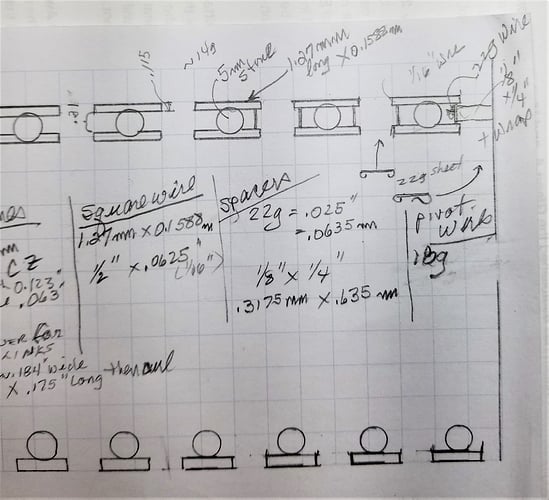

Here is my difficulty. How do I set it up to hold tiny pieces like 14g square wire so I can drill holes into many pieces at the same distance from the ends? The pieces are about 1/2" long. After that, I will be soldering 22g wire to join two pieces at a time with a set spread. Then use a setting but to drill a bit away so that I can solder a tube into the space.

There are no guides like a large drill press that carpenters use. I have tried to fashion from odds & ends. Any ideas on guides and how to hold the short pieces of square wire to that I can accurately replicate my drilling?

My trick to hold tiny pieces when drilling is to use double-sided sticky masking tape on a piece of foam core board. The foam core is easy on my drill bits. All the best!

Thank you so much. Another friend made me a sliding piece of maple that will slide in a routed groove in pine. My little pieces got so hot they scorched the original pine piece. It seems like it would that be a problem on the take or foam board.

the machinist approach is to get a small vise, and then put a bar across

the open end of the vise called a “stop”. Put the wire in the

vise, with the end against the stop, align it so the hole is where you

want it in the wire, then clamp the vise to the small table, the hole

will now be in a repeatable position. drill the hole in the wire, put the

next one in against the stop, drill, and repeat.

2 Likes

Thank you Mark. Rio sent me a small vice to attach to my small drill press. It will be attached tomorrow when I go into my shop. I will use what you suggested.

Hello Mark, may I ask what is the dia. of the wire and what is the size of the drill and what is the overall length of the finished wire pieces… Thank you, Regards, Richard Lucas… Lucas Dental Co.

The vice needs a jig to keep anything small (narrower than 10 mm) from being pushed down and breaking the bit. I fashioned a jig from a piece of hard maple to span the width of the vice and a protruding triangle which fits firmly into the vertical notch in the vice. Width of the main part is about 2 mm smaller than the piece width with a depth to bring the center of the piece depth to the center of the vice’s other notch. Notches are horizontal and a vertical with the horizontal being on the mobile side of the vice.

This worked great for me.