I have never attended a trade show. I know that MJSA NY is coming up soon, but I am a one man very small shop operation, not a manufacturer. Can anyone make a suggestion for what shows on the East Coast might be appropriate for me? I am always interested in tools and meeting the people with whom I deal. I am also interested in sharing ideas, problems and solutions. There is a lot of old discussion in the archives on this topic, but I couldn’t find much that is new. Thanks in advance…Rob

Rob,

Your not clear as to what you mean Attend a trade show?

there are 2 options,

- going as a visitor to look around to see what everyone there is offering and doing

or - taking part as an exibitor.

To consider this, you have to decide if your up to making lots of the same item to sell wholesale.

The only way to find out is go to a trade show as 1. to see what the competition is going to be.

Like yourself, im a one pr of hands operative and would never sell wholesale. Thats a mugs game.

Ive always designed, made and marketed my own products with the best and biggest exhibition unit youll ever see here in the UK and Europe, to the point that im always now sponsored ie , paid to come and show what I do.

What had you in mind?

Ted.

Ted…Sorry, I wasn’t clear, but you got me thinking. Right now I just want to attend a trade show where I can see new tools and materials and meet some of the people that I do business with. Since I live in Central New York, an East Coast show makes sense from a cost point of view. Long term, I have considered exhibiting at a trade show, but have no idea how to go about it, what show or if it would be worth my while. I do all of my business thru local stores, my website, word of mouth and from my shop. I try to keep my prices the same regardless of the venue it is sold from. I do pay commissions to some stores, so what I make on a sale is not the same as if I sold directly to the customer. Any thoughts are appreciated. Thanks…Rob

Hi Ted,

Do you have any pics of your exhibition unit…:-)…? What kind of program do you provide–demonstrations of your work techniques?

Rob,

I am also a one man operation, from upstate NY, I’ve gone to the MJSA NY show for the last 3 years.

I find the Gem Selling area to be real good, always come home with some nice stones to work with.

Seeing and Handling tools and work bench accessories is fun and informative.

Conversations with the people that man the booths can lead in unexpected directions. That is the way I switched to Luxi Polishing compounds.

One way to do it by car is to park uptown and avoid the midtown traffic, I use the garage at 82 st & Fifth Ave

I walk down to the show thru Central Park, in the morning, and come back in the late afternoon, by taking the subway back to the car.

It is an enjoyable day, I look forward to it every year.

I find Sunday to be a good day, as the traffic going in to the city is lightest.

Mike

Hi Rob,

If you’re interested in attending a trade show where you can see new tools and technologies, then MJSA’s Expo New York is a good option for you, especially given your proximity to New York City. It’s being held March 12-14 at the Javits Convention Center. The show’s exhibitors include suppliers offering bench tools and equipment, machinery, laser welders, CAD/CAM, as well as findings, precious metal alloys, gemstones, and pearls. In addition, there will be contract service providers of casting and refining services. (You can see a full list of exhibitors here.)

Also, new this year will be a tool testing station, which will let you gets hands-on with some of the latest new tools on the market, as well as a demo corner where experts will be demonstrating techniques.

And since you’re also interested in possibly exhibiting your jewelry at a show one day, you can also check out the JA Winter Show, which will be running concurrently at the Javits Center with Expo. This show focuses primarily on finished jewelry.

Registration for Expo New York is now open, and you can register for free. If it’s tools and equipment you’re after, I don’t think you’ll be disappointed.

Regards,

Shawna

Editor, MJSA Journal

Hi Janet,

Ive had at last! my IT guru scan in a couple of the prints I have here.

There are 2 layouts, the ist is a 20 by 20 ft setup, the second is the full frontal view is 20 by 10ft.

within this area half is the demonstration /production unit that has everything i need to make most of the items i have for sale. bowls excluded, the second 10 by 10 is the sales area.

So for example, in the second picture, this setup was for the production of the “Spirit of creativity” medal at Art in Action. the production run over 5 days was 500 off for the organisers, and me to sell as well to the 25,000 people that came to this event in July each year. In addition to the other work I brought with me. Sterling, bronze and titanium bowls and dishes, and all the other jewellery I make.

This setup starting with my own marquee takes 2 12 hr days to put together. A day to take down and load up in my commercial vehicle. I expect free parking , power and use of all facilities .

This sort of exercise is by contract, which needs a visit to meet the organisers , where I make a presentation what they will get and then what it will cost them, inclusive of all the tooling, materials etc.

I get seen at events and exhibitions and get approached by organisers to come to their events. not all materialise! some think it can be done for peanuts.!

Hope this is of interest.

Ted.

Thanks!

Do you just go about your work and whoever comes whenever they come gets to watch you? I mean as opposed to giving a presentation?

Depends on the contract.

If im paid to work there thats what I do. Tho usualy theres a crowd of people watching, and many ask questions? so its always a 2 way thing. As no one has made this Hazelwood and Dent drop hammer a fully portable easily dismantled machine for transport, it weighs a ton!, there normally a fixed piece equipment in a factory, it is a real crowd puller.

to give you an example, the 1st time I was asked to bring it to the dorset Steam fair, I was given a free hand what I could do. I commissioned a die for a commemorative plaque 3in by 2in oval for the event and chose to mint it at the event for the public to buy off the hammer so to speak.

well, i ran out of blanks half way through the second day, went home and that night blanked out all the brass and copper stock I had.

I finished up minting over 1000 in the 5 days all sold off the hammer.

This plaque has had some 5,000 plaques minted off it, in all metals as its an ideal shape to make a buckle. Then The science Museum London saw what I was doing, and from this enquiry came a series of 5 plaques called the great age of steam. These then were made into buckles as well.

When at Schloss Burg solingen am Rien, minting 500 silver coins at the Castle i was asked to mint a plaque celebrating the reunification of Germany. I chose the Quadriga the 4 horse scultpture on the Brandenburg gate Berlin.

This year, I now have the dies!!, Ill be minting in sterling the 2 classical bass reliefs sculpted by Bertel Thorwaldsen in 1830 in Rome. called Night and Day. Each in 3 sizes, for a range of products.

I feel im now good enough to interpret this masters work to a standard he would have approved…

Best

Ted.

I lived in the NYC area for many years and have been to MJSA many times. It is a good starting point to see tools and suppliers. I highly recommend it. If you buy from Rio Grande their classes feature the use of their tools and tool lists are provided at the end of class.

But as far as exhibiting at trade shows, what you describe as your current demo/production unit does not fit the format of the trade shows I have been to in the East. Of the wholesale shows I recommend you begin by looking at the American Made Show (formerly Buyers Market). At one time they offered education about trade shows, but that may be in the past. In Manhattan there’s the NYIGF show, but I wouldn’t make that my first show. I’m not as familiar with retail shows in the NYC area, but what I noticed is common to all the shows I’ve been at is that both space is sold in 10x10 sections and you must use their electricity, sometimes even their lighting. I have also never seen items made in any large setup or with large tools. At wholesale shows buyers look at samples and place orders to be filled after the show. Some do not allow items to be sold during the show. There are no demonstrations or production at the shows. What you are describing might be regional craft fairs, which are very different. Another problem I see is setup. Many shows give you an allotted set up time. Starting early and ending past opening is not allowed. Price is also a consideration. As expensive as craft shows can be, trade shows are much more expensive.

Instead of being an exhibitor at at trade show try contacting the show owners and work out a deal such as you have described making commemorative pieces on site. Perhaps the best exposure for something like that would be the Tucson Arizona shows every February or the Bead and Button Show in Milwaukee as both draw major crowds. There is also an online magazine describing craft fairs around the country as well as zapplication.org which lists many major shows around the country or by region.

Good Luck,

Mary

Hi Rob, Thinking is where it starts. so going to a trade as opposed to a retail show is good because its part of your research into what everyone else is doing so you can try and figure out how to do something different. Theres no point in competing with those who are more capitalised and connected. you have to be different enough to make it work.

Therefore next, go and visit all the craft shows you can find in your area, and even further afield, as the most important thing is the total no of people as in the public going to the craft,/ hand made show, and how many days it runs for.

Then you can plan how your going to offer something different to every one else.

Like I have. that puts you in the barganing position with show organisers how you can offer them some thing different.

When I first started in 1968 I drove 120 miles each way once a week to where the public was. That kept me going for 7 yrs till I found somewhere only 40 miles each way. that lasted for another 8 yrs till i had the chance to do a 4 day show, a pop festival ! which produced more in the 4 days than 3 months on a one day a week Europe.

In 1989 I included the H and D minting machine opening the door to a much bigger market for my work. the rest as they say, is history.

hope this helps.

Ted.

Hi Janet,

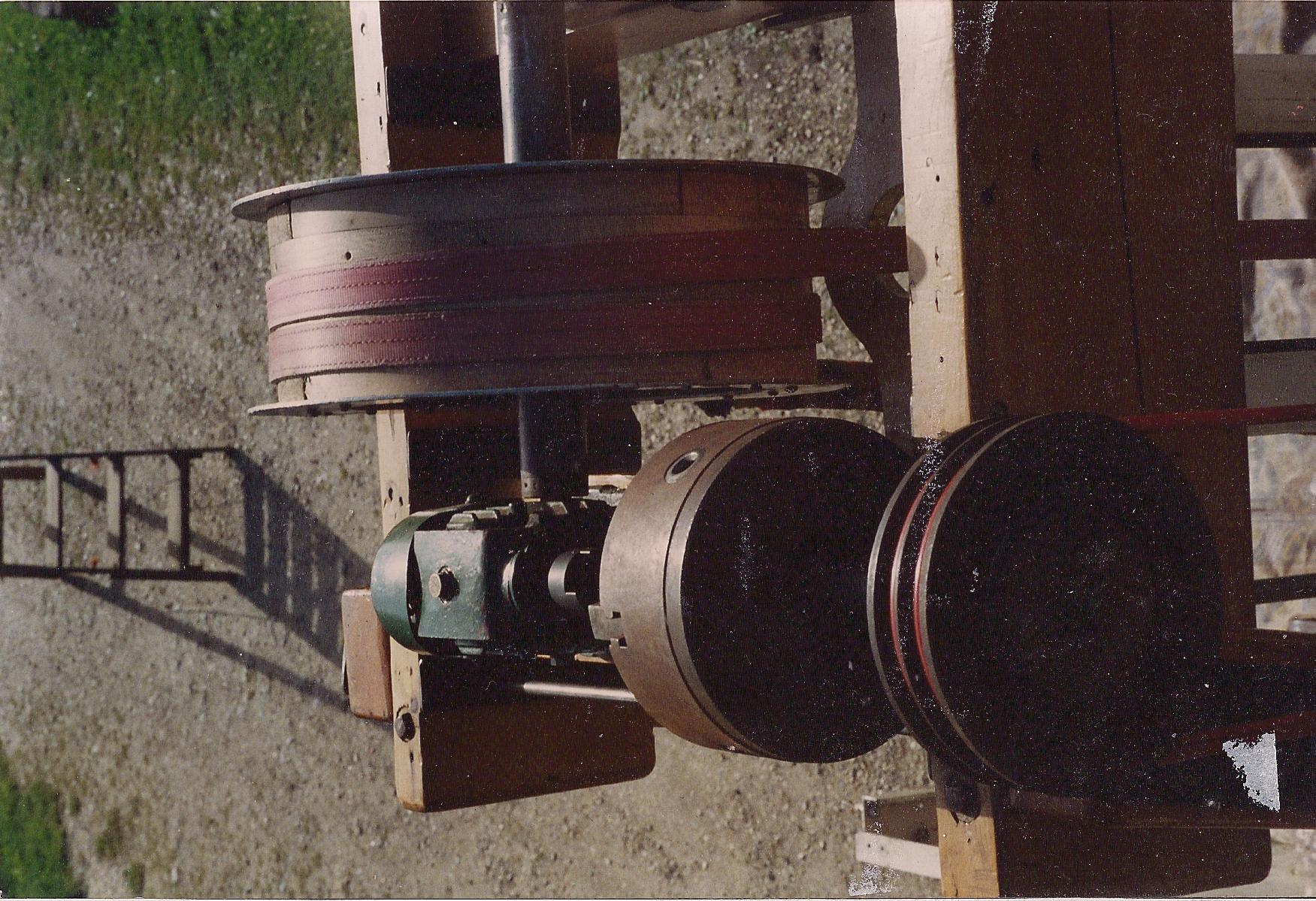

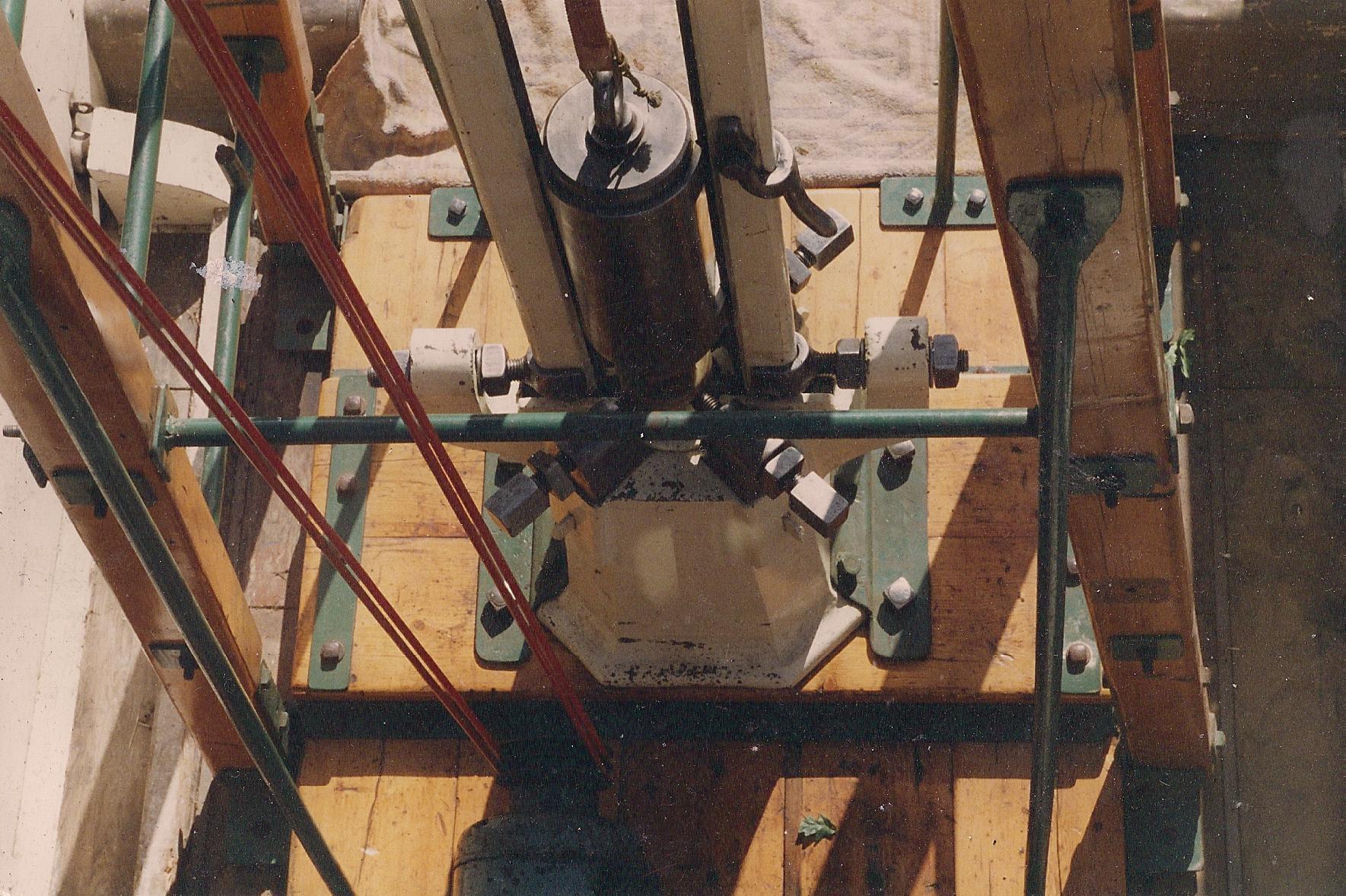

I had my IT guru doing some work here so asked him to add the following pictures to this thread. Also For you Brian Meek as you might like to see how I took the 4 basic castings as they were sold to jewellery production workshops in the 1890’s here in the UK (see att original brochure picture)and how I then built a portable adaption of these to fit into my expo unit as posted in the previous 2 pictures.

The only other pictures of drop hammers are by Hugo Kohl in the Providence Museum, which dont appear to be actually set up for production.

All the base timbers on their steel frame are 9 by 3’s and the side frames are 5 by 3’s.

the base is one assembly without the cast iron anvil, the 2 side frames are also ladder like assemblies. then the top frame is added.

Once this is assembled on site the 900lb cast iron base is set, then the top yoke then the guides then the hammer. This weighs 275 lbs. then the top drive gear.

Note that this is different to what is normally used.

I use 1 and a half turns of the lift strap which is a 3 layer sewn assy. 2 terylene and the friction layer of cotton webbing. It slides off load on the beech wood lift wheel that runs at 60 rpm. to lift the hammer requires only 15lbs of pull on the bell rope!. then a release by lifting the bell rope, it falls very quickly and is caught on the rebound off the work with the lift strap and parked with the safety lever. Remove struck metal, replace and repeat. Depending on the work one can drop say 6in or the full 4ft to get whatever tonnage one needs.

when all is set up, one can safely strike some 100 preformed silver or whatever non ferrous blanks an hour.

Hope this is of interest, as its probably the only fully working portable production 1889 jewelly making machine on this forum.

The dies of course are something else! Without them its just a very big hammer.

Ted.

in Dorset

UK.