Rob, CoolTools began as a metal clay supplier and has evolved into a trustworthy jeweler’s supply company. They are a terrific company to deal with, with great customer service and a wide range of reliable products. Glad you’re working with them. Any questions you might have about enameling, you can write to me, or go on facebook and look for enameling groups. I like Enamel Guild North East, but there is a wide range of groups. Check them out. Welcome to the world of color.

Hi Rob,

Check out Schlaifer’s Enameling. Their website is www.enameling.com. They have a good inventory of enameling supplies and tools and they take the time to ship economically.

Donna

Thanks for the offer of help. I will take you up on it as I am not shy. Besides, I haven’t been the student for a long time and find it a lot of fun. We have recently deleted our FB page. It just got too tedious to look at with very little in return for the effort. I do miss marketplace and some of our local pages that would tell us what is going on in our community. We may be back sometime in the future. Meanwhile it is YouTube, enameling sites and all the great people on ganoksin…Rob

I have looked at Schlaifer’s website. There is a lot of good information on it. Thanks…Rob

Hi Rob,

If you haven’t already discovered them, Enamel Art Supply and e-namels.com are other great suppliers along with ordering directly from Thompson Enamel.

Janet

Enameling update:

So far I have experiemented firing enamels using a torch, a beehive kiln and a 10 brick kiln. Far and away, I have had the most success with a torch. I would like to make a trivet out of titanium strips to use when torch firing so that very little of the piece being fired is covered by the titanium. . Titanium is slow to conduct heat and stays clean. I would weld it with my PUK. Any thoughts about using titanium are appreciated. Thanks…Rob

Hey, Rob. I just use the cheap three pointed steel trivets you can get from most any enamel supplier. I paint the edges of all of my trivets with kiln wash. Warm the trivet with a torch flame a bit first and then paint on the wash. Keeps the hot enamel from sticking and works like a charm. However, if you want to make a trivet out of titanium, that would probably work great. Anytime you can make your own props is a boon as you get to customize them to suit your needs. Post a pic of your prop for inquiring minds.

Nancy

Nancy…I hadn’t read about painting kiln wash on trivet edges. I have been filing just the edges with an old file. I made a titanium torch fired trivet for some flat earrings that I have been experimented with. Titanium welds very easy with my PUK. I wish that silver welder as easy. I will attach a link to some pictures that I took this morning of my new enameling bench, the titanium trivet and my experimental earrings. I bought the flux that you suggested and it works great on copper as well as silver. I welded the trivet so that the earrings sit on the edge of the titanium strips. This allows more of the bottom of the copper earring to be exposed directly to the flame. I started out using my trusty Blazer butane torch to torch fire, but have moved to my propane and O2 Meco because it doesn’t run out of gas every ten minutes. Thanks for your suggestions…Rob

Hey, Rob, that titanium trivet looks like it works great. Perfect for those rectangular earrings. Well done. If you’re filing the edges you may not even need my kiln wash trick. I’m too lazy to file plus I’m precious with my files. Don’t want to touch any file to steel as I can’t trust myself not to cross contaminate. Also, you have a super nice and neat setup. Thanks for sharing!

I have since modified the trivet adding another cross piece a bit close to the adjacent one to hold a smaller shape. Needless to say, I have used up my stock of titanium strips and ordered more. I will likely make another trivet that will fit into the beehive kiln that allows the piece to sit lower in the kiln than a traditional three leg trivet would allow.This gets the piece closer to the heating element. I like the idea of the beehive because it used less electricity than the bigger kiln, but I can’t always tell if the enamel has finished fusing without removing the top and dumping heat. Besides, it is kind of magical to watch enamel fuse when torch firing. Next steps are to make a few more simple shapes and then mix colors on one piece. I did learn not to boil an enameled piece in pickle to remove the copper firestain. It does remove the firestain, but it also dulls the enamel. Two steps forward, one step back…Rob

rmeixner, Rob, I would like to suggest that you sign on for https://merryleerae.thinkific.com/ . She is an experienced enamelist who offers an incredible amount of information, some of which (perhaps most of which) will be useful in your experiments with enameling. You are not alone with using the beehive kiln, as there are a number of enamelist who use that type of kiln. I prefer using my Paragon kiln with firebrick insulation. It doesn’t lose heat the way that the newer SC-2’s do when opening the door to check the enamels. The difference in electricity usage is negligible as the beehive does use considerable electricity. It’s a balance between recovery and what it takes to maintain the correct temperature.

I will look at the website that you suggested. I have a perfectly good firebrick kiln, but right now I just like torch firing. My original goal was to add bits of enamel to finished jewelry. This can only be done with torch firing as the piece would not survive a visit to the kiln. Thanks…Rob

Rob, would love to see how you intend to add bits of enamel to finished jewelry. Post images, please.

I will when I get there. Stay tuned…Rob

Making good progress applying enamel to flat copper surfaces. I am a bit challenged to get the finish on the copper backside that I like, but have come to appreciate the work that pickle does. I don’t want to counter enamel. I am looking for small flexible diamond and resin discs that I can use with my flexshaft to finish these surfaces. I did try soldering my first silver bezel with eutectic solder and was able to fabricate it the same way that I do with hardsolder. Applying enamel caused the metal to slump a bit, but the joints held. Lots more to learn and I may also look into learning to work with PMC. I am now 76 and am looking for less physical ways to work with precious metal. Thanks for following my enamel journey. The sun came out today in Central NY for the first time in two weeks. We have had steady rain for most of that time. I had to plant potatoes twice. They rotted the first time…Rob

Rob, Sadly, there is no PMC any more, but there are lots of other Fine Silver metal clays. I can teach you to use metal clay (I’ve been teaching metal clay for over 20 years). Private lesson. Price-y, but I’m worth it. Message me via my website: lindakayemoses.com.

Also, I enamel on sintered metal (fired fine silver metal clay) and I never counter enamel. Just sayin’.

Thanks! What do we call it these days? I have been watching Pam East videos and what she does with metal clay and enameling looks like fun. I looked at your website and it looks like you have too. I have always worked in fairly traditional materials and methods.They are, for me, very physical and have taken their toll on my body over the years. I am looking to add other types of less rigorous media to what I do so that I can keep on doing it…Rob

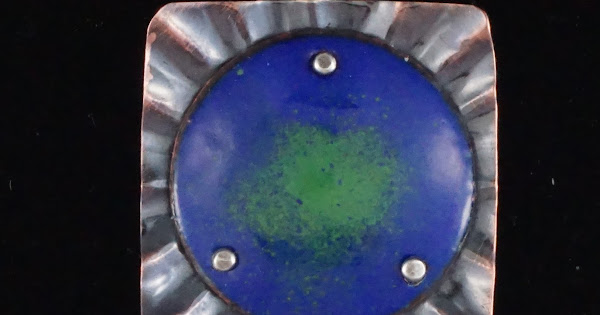

As I continue on my enameling journey, I find myself learning how to set an enameled piece. The challenge is to avoid damaging the enamel with the usual forces associated with bezel setting. I made a series of enameled discs and have set them in several different types of bezels. I have learned that traditional hammer and punch setting with a thick sterling silver bezel is likely to damage the enamel. Following is a series of pictures of successes to date. They include a continuous fine silver bezel that was carefully moved over the discs, A tab set bezel, a prong set bezel and one that is rivet set. None are for sale and will likely go into the scrap box, but I have learned a lot about how to set an enameled disc. I am enjoying enameling a lot and will continue this journey. If there are other ways that I have missed, please share them. Thanks…Rob