Hi everyone. I’m a hobbyist jeweler and have a small and very humble garage studio. For years I have just been using a large Smith torch of propane and a large oxygen bottle for the small amount of casting I do which is literally like once every 2 or 3 months. The large oxygen tank is like those ones welders use. It’s extremely heavy and for years I just get it filled up once a year but I’m getting tired of lugging it to my gas supply company. I’m talking about the 5 or 6 foot high tanks.

I was thinking of switching to a propane gas forge to melt metal like the Devil Forge is very popular, for example. Then I just use propane which are small and can move those with a finger or two. But…my question really to all your professionals who use tools every day is what electric melting furnaces are worth it, (if any). Are there any ones that you have used over a year or two and didn’t fail/break? Even though I only cast a few ounces and only 6 times a year, I like tools that will last forever. For example, the vacuum casting machine I use is 35 years old and works well. (An old commercial grade one I found at estate sale).

Thank you.

1 Like

For years I have melted scrap in an open crucible and cast ingot in open molds, closed molds and sand depending on what I was casting. I used a Meco with regulated propane and O2. When I got rid of the large tanks, I went to propane in small 1 lb. cylinders and O2 from a concentrator. It doesn’t have the heat needed to do a large melt. I bought the smallest Devil Forge furnace that they sold at the time. It was a great furnace, but I had to use it in the driveway and it was just too big for my occasional 3-5 ounce melts. I sold it and bought a Table Top electric furnace that works very well. I have a ventilated spot in my shop where I can make a temporary place on a bench. There is a size issue with it too. The crucibles wear out after maybe 10 firings and they are expensive to replace, so I only use it when I have a large amount of scrap. Again, it works very well. What I typically do now for bigger melts, but not big enough to use the Table Top is to bring a smaller O2 regulated cylinder in from my shed and move the O2 hose over to it. I have all the flash backs and check valves in place. When I am done casting, I just put things back the way that they were. The Devil Forge furnace was really cool to light up and it will definitely melt metal. If I did brass casting I would still own it. They aren’t that expensive and they also make propane forges. Good luck…Rob

3 Likes

I have one, but I would avoid the brand I got. The design is not great and the wires I have direct contact to the metal structure which is caused me to have to rebuild it a few times.

I think the brand is PMC. When I contacted them for replacement parts, they were definitely over pricing insanely and I was able to get the exact part for 4 to 5 times cheaper off eBay.

If you have the ability to make stuff, it’s really not that complicated of a system. But it’s just a lot of time and fiddling and learning.

3 Likes

I remember your comments regarding Table Top furnaces when I bought mine. I liked the fact that you can reconfigure it to accommodate different sized crucibles. This is a feature that I didn’t find in other furnaces. I really am not worried about the cost of replacement parts. I don’t use it enough for this to be a concern. Regarding the design, it comes with a pair of tongs that will easily remove the crucible allowing me to pour the melted metal into my crucible. Other designs that require that you pour the melted metal contents by actually pouring the entire furnace much the same way as you would a coffee pot never appealed to me. In the end, I buy tools that I hope will work for me. If they don’t, I try to sell them. If not, they will go into my tool museum…Rob

2 Likes

I hope it lasts a long time! As long as it wasn’t frying relays it worked great

1 Like

Hi,

my friend bought one…i have it, but have yet to use it…

one thing that has been on my mind is whether i will be able to handle the longish crucible with tongs at the neck, and pour it into a relatively small mold hole…

julie

1 Like

Hi,

as an aside, you might/ should be able to switch down to a smaller, more manageable oxygen tank size…

julie

1 Like

I had the same concern about using the long handled tongs, but it turned out to be no different than pouring from an open crucible on a wire wand, at least for me…Rob

2 Likes

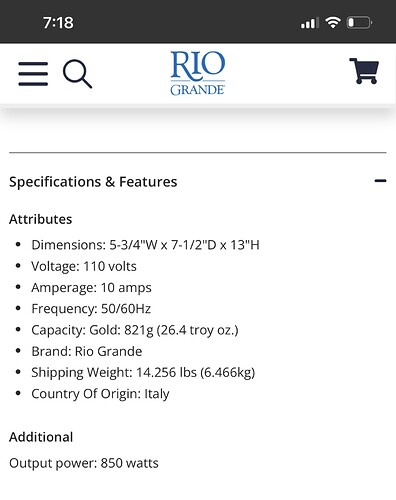

Thanks for the replies. The Rio Grande one looks well made. There’s a popular made in Italy one too I see online? I think it starts with a “V” like Ventura or something? It looks very industrial and serviceable like many Italian made machines. I like the idea of getting a smaller oxygen tank but then I’m making even more trips to get it filled and will cost more in long run maybe? But you have a point that it might help me avoid taking a risk on an electric furnance. It looks like 800 dollars or more for a decent one and my garage studio is high humidity so I try not to add electronics in there. That said, the PID temperature controller for my small kiln sits in the hot humid garage for 6 years now and hasn’t failed. I can’t believe it.

Hi Rob! Thanks for your information. Which Table Top electric furnace did you buy that works well? And is it possible one can buy upgraded crucibles? I can’t believe they only last 10 melts so I’m glad you warned me on that. I have cheap open torch crucibles that never failed so why can’t they just make the electric furnace crucibles out of the same stuff?

10 is what they tell you, I think that they will last longer. Electric furnace crucibles are made from graphite, open crucibles are a ceramic material (I think). I have used my open crucibles forever. I like the idea that the Table Top furnace is the same regardless of the size of the crucible and you can change the crucible size by replacing the top with a hole the size of the crucible that you want to change to. I think that I started with a middle of the road size. Again, I don’t use it a lot, so I can’t speak to the cost of replacement parts that have been identified as a problem by others…Rob

Just my two cents: do you really need it or have you been getting by well enough without it?..one that lasts forever is great until it’s time to get rid of it…prior to doing hobby jewelry, I already owned an oxyacetylene set up with a 180 c.feet 02 tank… I have the two stage regulators, an extra set of regulators and cutting and welding torches, along with a light duty MIG welder. I got them ages ago to do DYI autobody repair, but used the torches to cut scrap steel mostly to make heavy duty windchimes, mobiles, used the MIG to repair steel frame garden furniture, and other household uses and weld together the chimes, mobiles, etc.

Melting even large batches was easy and fast with oxyacetylene. Oxypropane also worked fast with higher rates of gas flow. I really agree that dragging heavy gas bottles to the gas retailer is a pain…high ouput (8-10 liters per minute) non medical oxygen concentrators (medical ones cost more) will produce enough 02 flow for large melts and provide for all other uses…eliminating the need to haul heavy 02 bottles… using two connected (4L/min) 2 concentrators to achieve higher flows was discussed on another thread, with the consensus being yes it’s possible and okay…rmeixner mentioned that he got one because his torch wasn’t up to melting large batches…any 02/propane torch as a very high combustion temperature, but the instantaneous heat output is more important and is dependent on flow rates…I don’t have that problem with torches for steel and compressed gases…I also don’t think that high capacity electric induction furnaces aren’t worth the cost, unless you are doing jewelry casting frequently for commercial sales…table top electric resistance furnaces are great until it’s time to get rid of stuff… I was forced to retire from jewelry making after I developed neck and shoulder issues. My problem now is to get rid of stuff… Your problem is too many choices.

Thanks, yeah I read up some and apparently the more the graphite crucible is exposed to oxygen when it’s hot, the faster they degrade. Maybe the high quality electric furnaces have tighter tolerances to expose crucibles to less oxygen? The 800 dollar and up ones actually make claims about the crucible being exposed to less oxygen. but… it might just be marketing. I would think only the commercial grade 20,000 dollar machines actually can reduce exposure to oxygen.

All good points. You are the second person that says it might be better to just get a smaller oxygen bottle and keep using gases which are reliable. I am a bit concerned with paying 800 dollars for an electric melter and if it were to break, can I even get parts for it? I won’t mind paying 800 if the machine is serviceable. If I can just put a new element in or another PID temperature controller like the kilns, I think it’s okay. I’ll keep thinking… Thanks for your input.

please see my second post. I had to make choices as a hobbyist also… best regards, jsf

sorry I deleted my post by mistake, my bad…

IMHO:

1.) when buying expensive equipment (think new car), serviceability and warranties are important. I could get stuff on line for cheaper, but went to a local jewelry supplie retailer to get stuff. Being able to talk to are real person who could help with manufacturers’ warrenties helped me save on replacing a new rolling mill… this cost me, at the time of purchase, $1,200, more like 2K at today’s equivalent cost… after a couple of uses, one of the threads broke on the rod rollers… I was able to return it and get a replacement for free via the retailer, no questions asked. A $800 electric furnace that’s reliable would probably be enough for a home hobbyist… a 20K furnace would be better suited for a commercial jewelry making workshop with employees, written off as a business expense… I live near a large commercial operation… bought sheet and wire from them before I got the rolling mill… they did asyembly line production. However, $800 is still a good amount of money to invest… good service and replacement parts do count.

2.) So far as 02 is concerned, I already had an 02/acetylene cutting torch… cutters literally burn thru steel by oxidizing molten preheated steel with a jet of pure 02… that required a larger 02 bottle. Using the multi-orifice cutting head preheater jets with an 02/ acetylene mix provided far more heat output than needed to melt. The heat output could be adjusted down with the second stage regulator and handle knobs, but open crubible melting took seconds rather than minutes.

Julie’s suggestion of getting smaller 02 bottles has to meet your present and potential future needs- Lugging a heavy big bottle a few times versus filling a smaller one more often…I already had a big one, so I stuck with it… lasted more months with hobbyist work…

if 4-8L/minute 02 flow is sufficient, you could dispense with high pressure bottles entire by buying an 02 concentrator…was tempted to buy one, but not necessary with a big bottle.

3.) Even if you have a gas fired furnace with a neutral or slightly reducing flame, graphite crucibles will eventually wear out. Electric furnaces can’t completely exclude atmospheric 02.

Induction furnances work fast, resistance ones should be preheated to melt quickly.

I hope this helps, best wishes, skh