I wrote to Ganoksin yesterday about my difficulty with a disc cutter. The punches are either dull or I am not using it correctly. Where do I find my posts? Thanks.

You may never find it. Just ask your question again and we will try to reply. I have had the same disc cutter set for years and it works fine. I use it in a press most of the time to make sure that the force is applied perpendicular to the cutter. This is more important for the smaller cutters. I know this as I broke one hitting it at an angle. If you don’t have a press, place the cutter on a solid metal surface like an anvil with a rubber pad between to protect the anvil surface. Be carefully how you strike the punch with a hammer. Use a metal hammer and strike such that your striking force goes straight through the cutter. Older and less expensive cutter punches have a square edge that passes through the cutter hole. This means that all the cutting force is applied equally all the way around at the same time. Newer and better cutters have an angled cutting edge on the punch. This applies the force progressively around the cutter hole. The fit between the punch and the hole may also be less accurate for older and less expensive cutters. Some metals are more sticky than others. Brass is sticky. You might try playing with the level of annealing of the metal to avoid this. Finally, from time to time, it is suggested that you can make small abrasive discs with your cutter. This is true, but it will dull your cutter. Finally keep it clean, dry and you might add just a little light oil. Good luck…Rob

I looked all over for your post as well and I don’t see it anywhere. Like Rob said can you repost your question.

To answer your question about how to find your previous posts. You can click on your name, then activity. Then all of your posts are listed.

Thanks so much!!

Jeff

Hi Mayci,

Let me start by admitting I don’t cut discs frequently and I own a cheap disc cutter, but I do have a couple of suggestions. First, I’ve been able to sharpen the edges of my punches by patiently sanding the face gently using 400 and then 600 grit sandpaper on a very flat surface. You have to be careful not to rock the punch as you are sanding it. I have only tried this with an inexpensive set. I would be surprised if you would need to do this with a premium set.

You might also want to watch the video below. I can confirm that the trick Andrew Berry suggests with a bench vise works like a charm. I own a heavy brass hammer but I haven’t used it to cut a disc since I found this video. I’m not sure I would stick an expensive disc cutter in a vise but this technique has certainly improved my experience with my cheap disc cutter.

Good luck!

Melissa

Andrew’s videos are always informative. I learned to add a shim of equal thickness to the material that you are cutting to the opposite side of the disc cutter. This makes a lot of sense, especially if you are cutting thicker material. While I do have a very nice press, I don’t have a large vise in my shop, so I can’t use the vise method. It does seem clumsy to me. My biggest concern is that the material being cut can easily slide out of alignment with the cutting hole until it is held in place with compression. This can also happen using a press. I have done this before and you can get a nice disc with a flat spot. Thanks for sharing Andrew’s video…Rob

Greetings Mayci

I have used the same disc cutters for 25 years and I am going to replace them, probably with the same product. I bought a $50.00 set of Beadalon disc cutters (5 disc sizes) at a 1/2 price sale at A.C. Moore with the intent of getting a better set as soon as I could. $25.00 was pretty approachable for me at the time. I haven’t yet. Not because I can’t afford to but I just haven’t had the reason too. The old set are only now starting to show some wear. I cut most of my silver and copper discs with a hammer for years. And I had been pretty successful in that time. But I bought 20 ton press 15 years ago and that was a game changer. Less wear and tear on me and the cutting surfaces. I have a large vise but I don’t use it a means of driving the cutter. There just isn’t room on the benches. But I suspect it would work fine. I would be concerned about alignments. A large vise doesn’t have to be mounted in the traditional horizontal manner on the bench. I have seen them used in boatyards and welding shops mounted so the vise faces are horizontal to the floor. These usually were for jobs proprietary to that particular shop. Pressing bearings into housings isn’t much different from pushing a punch through a disc cutter.

I haven’t tried using a backing material for a cleaner cut, never crossed my mind. I can see where an angled cutting surface on the punch would be a benefit.

Good luck with your projects. I will bet you will get a good answer from the folks on this forum.

Don Meixner

I completely understand the concern about alignment and it did take a bit of practice to get to the point where I could consistently get good use of the metal. My vise is bolted to my bench in the traditional horizontal manner so I cut my discs exactly as Andrew demonstrates in his video. I only do this to cut “throw-away” copper discs that I use to produce quick enamel samples so I can test enamel colors direct on copper. I don’t use these samples other than to store them for future reference in a binder. I’m pretty casual about waste with my 22 gauge copper, but you can see from the attached photo that I’ve gotten pretty good at using this vise/cheap disc cutter method with minimal waste. I can knock out 20 or 30 discs in about 15 minutes.

disc cutting.pdf (145.5 KB)

Thanks so much for your informative message.

Hi Melissa, thanks for sharing that demonstrative video. It has given me ideas for using my new disc cutter. Has anyone any suggestions or comments regarding using an arbor press rather than a hydraulic press?

An arbor press will take only one pull on the handle while a manually powered hydraulic press will require a number of pumps on the handle, which takes a lot more time with no extra benefit for cutting discs.

I haven’t seen one recently but I bought a 2 ton arbor press at a farm supply store. It works a treat.

(A check on Amazon shows that they sell 2 and 3 ton arbor presses. Some of the 3 ton presses do not look as robust as my 2 ton, so shop carefully. Mine weighs 100 lbs. so keep that in mind if lifting might be an issue.)

For extra power or just ease of use I’ll slide a 3 ft. length of black pipe over the handle. It has more of the working capacity of a 20 ton press than the name “two ton” suggests. This is very helpful with 1 to 2 inch diameter disc cutters.

A 1 ton press would be fine for disc cutters of 1 inch and smaller.

For reasons that Neil describes, an arbor press is on my short list of tools to buy. I would caution that some press designs may make it difficult to get the disc cutter in position to use the press without impacting the way that your stock is positioned in the disc cutter. I am often cutting up to 10 pieces from a strip of material in my disc cutter and the the shape of the opening in my hydraulic press dictates how the strip is oriented in the disc cutter. This may be more critical when using an arbor press. You will also need to support the entire disc cutter body when using an arbor press as they don’t have a wide flat area on which to rest it. Finally you may go seasrching for the piece that you cut out and even your punch as the arbor press design is open below. You might consider placing the cutter body on a piece of steel plate before you do the pressing. Just a bunch of random thoughts as I wait for the coffee to get done…Rob

Rob, with only one large post vs a hydraulic press’s two, placement of work is less restrictive. About 270* or more is open for positioning long pieces of metal. The limiting factor for me is my having heavy equipment on both sides of my arbor press for lack of room.

Here’s how I cut 1/8" to 1" discs:

The urethane pad protects the bottom of the cutting die from being jammed against the base when the die punches through.

For larger things the round base can be removed as below. The sponge catches the cutting die gently when it punches through, which it does, smartly.

I use the black pipe cheater bar seen in the first image for extra leverage with large discs and thicker metal.

I lube the cutting die, which makes it easier to cut and also makes it a good bit easier to remove the cutter from the stamped stock, which can hold on pretty tightly. Sometimes I need to hammer the die out so I do it into the sponge which keeps the die from hitting the floor or other hard surface when it breaks free.

This is one of the large tools I would definitely replace if it was ever necessary.

Neil…Coffee long ago drunk, a productive day in the shop as well as a visit to the zoo with my wife and I am almost ready for bed. I don’t have an arbor press, so my comments were based on what I imagined the case would be to use an arbor press with a larger round disc cutter. I can see from your pictures that, at least for your press and your style of cutter, there is no clearance problem. I have to be careful with my press that I don’t hit the stock that I am cutting out of alignment when I put it into the press. You appear to have solved the problem of the cut piece and punch disappearing. I think that an arbor press may be a way to serve some of the needs that we typically associate with a hydraulic press and an arbor press is a lot less expensive than a hydraulic press. Thanks for the pictures and help addressing my concerns about using an arbor press with a disc cutter. Right now I am getting ready for what I suspect will be a fairly active show in mid July. Other than a house party at Christmas, it will be the only show that I do this year. This preparation requires lots of duplicates where I might otherwise only make one to fill out my inventory. I have been making good use of my press and disc cutter. At some time I will look at arbor presses and decide if I really need one. What I really want (don’t need), is a fly press…Rob

That’s a problem for me too. Mostly I just hold the die down while I move the disc cutter under the press. That doesn’t always work, so it’s a do-over…

I don’t cut from long lengths of sheet so my lack of room at the sides isn’t an issue, just simple disc cutting such as the 2 cuts used for this:

If I had the room and the need I’d use 2 5/8" of 2x6 and plywood on each side of my press’ base, so larger stock could just be slid along under the plunger for repeated punches.

What I really want (don’t need), is a fly press

Amazon surprised me by not listing one. Some amusing things popped up including a small white weight bench for $5,069.09 - don’t forget the 9 cents!

Even eBay lists only a few, and the prices… ![]()

Good luck with your show!

Neil

I do a similar piece as earrings. Fly presses are expensive. The blacksmith that our son and I took a class from has a couple and he showed us what he does with them. Again the expense is in the tooling that you use with it. See the attached…Rob

The anxiety of being a Gear Head keeps me awake at night. If it’s not jewelry shop tools it’s guitars or banjos.

Neil, what type of arbor press are you using? I have a one ton press from Harbor Freight that will punch small discs out of 22 ga. Copper or Sterling but it requires a pretty stout length of pipe for a torque multiplier. It’s primary benefit is that it is small and takes up very little space. I rarely use it for anything but leather work these days.

I really don’t mind the time involved in punching discs out with my 20 ton press. It is certainly more dependable than my four pound hand sledge with fewer mistakes.

Don

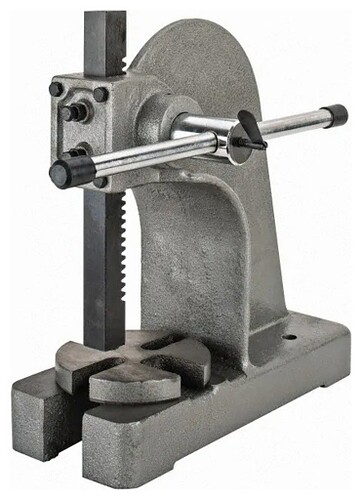

Don, I didn’t know there were types. If you mean brand name, there was none. However I did a Bing search and found an image that is exactly like mine:

It looks small, is not. It is 18" tall at the back, 17" front to back base. I got it years before buying a Bonny Doon 20 ton hydraulic. The arbor press was $100 for 100 lbs. from a farm & ranch store called Big R, which became Coastal Farm & Ranch. I was using a 1 ton arbor press, then a Harbor Freight 20 ton shop press at the time, the 2 ton did much of what I needed much more easily & quicker.

Years later I got the Bonny Doon Mk III after seeing a deep draw video on Rio Grande. They showed all the deep draw tooling in the video, which I of course then wanted, but they divided the tools into 2 kits for sale, and the cost was doubly prohibitive, so the extra height of the press is of no use to me, is a disadvantage, and I skip the Bonny Doon unless I need to do something that the arbor press can’t. It is so much quicker and handier - one pump instead of many.

They have 1 ton arbor presses, likely made by the same outfit in China, that look exactly like mine, but they are maybe 1/4th the size in volume. I had one, donated it to a school when I saw the 2 ton. There is no comparison between the two. The 2 ton is much more than twice the 1.

I’ve seen 3 ton presses on Amazon, would look at one of those now, but some / most mentioned ratcheted gearing and I’d need to see if the ratchet gears were robust enough before buying.

I see small is all in what you view large is. Mine is a Harbor Freight press. I bought it with greater expectations of it’s capacity. It is meant to press in bearings and such. And like I said about 3’ of pipe and you can press out some disks. And as I also said I don’t mind the time it takes with my Bonny to do the same job. But if someone were to give me a fly press I wouldn’t turn it down.

Don

Hi,

i am not sure if this was mentioned…but i was advised to use a brass hammer when sticking disc cutter punches…probably steel punches in general…rather than hardened steel hammers and sledges…

julie