Has anyone ever tried to centrifugally cast sterling silver using delft clay instead of investment. The flask would not need to be burned out or heated prior to casting. I don’t know if this would create a better casting than gravity or if it is a waste of time. I have a complete lost wax casting outfit that I bought 45 years ago and have never used. I do a lot of delft clay casting, but no lost wax. subject to Orchid feedback, I may give it a try. Thanks…Rob

im keen to give it a go

Les

Interesting concept. I love out of the box thinking. My guess is the initial shock of the centrifugal force may owner one the bonding of the clay/sand. Please let us know the results.

Regards RLW

Good chance molten metal might come out of the middle or just pop out the bottom

I suspect that you are right. If I do this at all, I will do a dry run first with no melted metal just to see how well the compacted clay survives. I am generally happy with the results that I get with Delft clay. I typically use it to cast an odd shaped ingot and simple shapes that I can refine into a finished piece. I am just curious if I could get a better casting using the centrifugal arm. More when I know it…Rob

Ah, now your talking my language when speaking of a Centrifugal Arm…  Regards, Richard Lucas… Lucas Dental Co.

Regards, Richard Lucas… Lucas Dental Co.

Richard…It is about 40 years old and was purchased from Gesswein. It looks a lot like one of your casting arms. Were you making them 40 years ago?..Rob

This sounds interesting. Wear protection just in case!

Hello Rob, yes, I was dealing with Gesswine and HR & B. Jadow over 40 years ago and we were making casting machines since before 1960. Over the years, we have made many improvements to our casting machines. Not too many companies around today that manufacture casting machines. I do believe that Kerr gave up on casting machines, I guess because the Chinese have copied them and well, you be the judge. Have a pleasant day, Regards, Richard Lucas www.LucasDentalCompany.com

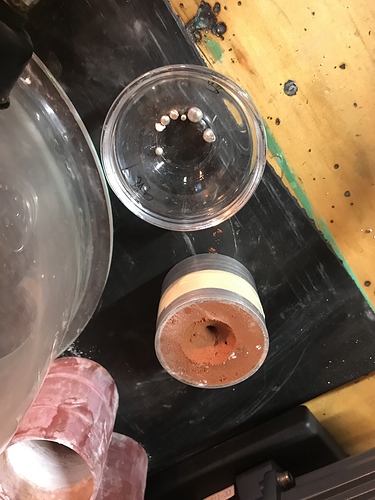

I Did it today and will post as a separate thread. as well if i can figure out how to do that but here we go. Had one of my students set up a mold with a model target weight of 1gm. used 4 gm of sterling silver 2 vents and a 4mm sprue gate. The mold was hammer packed to far tighter than i would ever do using gravity. Using a Lucas Long arm centrifuge wound 1.5 cycles. Preheated the crucible to a good glow put in the silver and premelted it before dropping the mold into the cradle. The mold was taped all the way around equator to hold it together. Remelted the silver and let it go. Cast worked perfectly. Now blow out no fuss very little in the way of margin lines and no porosity. We have reproduced the results several times. here are some photos.

Hi Richard. Have a look at the photos below. Thought this might interest you as i am using your long arm centrifuge.

Glad to hear that it works. Seems like a delft clay mold would be a lot easier to prepare than investment as long as the model can be removed prior to casting. Thanks for passing on your experience…Rob

Hello Les, one thing for sure…you are using the “Best” Centrifugal Casting Machine that is still manufactured in the USA… Regards, Richard Lucas

Next ill try a polystyrene model left in the mold. If it works more complex undercutting can be included in the model. Stay tuned.

The area of concern would be where does the melted polystyrene go during the casting? Will it have a negative effect on the metal and or cause porosity, etc.?

Have you had a chance to try this yet?

not yet. The polystyrene vaporizes. I have done this on a larger scale and had no issues with porosity or incomplete castings. Might have both of these on a smaller scale.

Wow/ That’s a cool thing to know it works. Will spare me some time going through the usual steps. Thanks, and thanks!