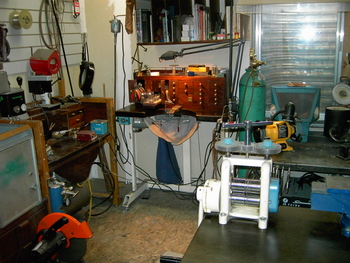

USA It had needed cleaning for quite a while now, all I lacked was the motivation, which I found with this thread. It had been a while since a jewelry project and the debris and scattered tools were an accumulation from several other projects. No way was I going to show you a room that testified to the recent detonation of a medium yield device.

The bench is crafted of vermilion, a tropical hardwood also known as purple heart. The top itself is Benalex, used commercially to mount power units (diesel engines) on when installed in factories. Think of Masonite 3 inches thick. that top weighs 100lbs. took 3 hours to cut that circular piece out.

The bench features compartments that the tool racks extend out from on bearing glides, and a bunch of drawers.

The bench pin is inserted into a slot in the anvil and is secured by a vise grip type locking device underneath. Pull forward to release and push to lock. I have adapted several devices to fit the pin slot: A standard reversible wooden pin with rubber on one side, and the dust catcher I use when grinding/smoothing the work, and a tool I designed to accurately cut faceted stone seats on a set of prongs. The pin pictured has a “third hand” mounted on it. Now I need to figure out how to mount one of those on my forehead.

There is an old cloth bag Kirby vacuum ( minus the handle) mounted to the underside of the bench top with the intake mounted through the skin to provide positive dust/particulate removal during sanding/smoothing operations with the Craytex wheels.

The Foredom hand pieces are plugged into a speed regulator (those things are great!) that is right next to a small motor whose shaft goes through the skin to mount various buffing heads on…(right in front of the vac)

The foredom motor is suspended from the brass rod above where you see the coping saw hanging from.

I can only show a portion of the shop, but it is also used for welding, grinding, plasma cutting, lapidary, and generating generally offensive odors. Yessir, right at home here, and as you can see, it ain’t pretty.

I have really enjoyed seeing the work areas from the members here. Great thread