How do people make molds of large items? Thinking almost the size of a cowboy’s belt buckle. I can’t seem to find anyone who makes mold frames large enough for some large earrings I’ve made.

Does anyone know where I can find some?

Thanks in advance.

Elizabeth

Use a section of large diameter pipe, can even be flattened to and oval if that is closer to the size needed

Here you go https://www.speedymetals.com/ if you go in the steel section and select rectangular or straight tube or pipe. They have it up to 8 inches by 12 inches in size. You just tell them how high and they cut to size.

I have made mold frames from rectangular aluminum stock purchased at the local hardware store. You will need to grind the metal a bit at the bends to make completely flat.

Is it already in the shape of a hollowed rectangle?

I’m not understanding the thought process here, as I am unfamiliar with the material. Does this require soldering?

Thank you

I’m afraid I need more instruction on this. What all do I need to do to it? Thank you

Nothing much, you specify the size you want and how long they cut it and ship it to you. The only thing that might need doing is taking a file and removing any shart edges from where it was cur

This process could be used for a closed mold frame but would require (Aluminum solder) soldering the frame closed after shaping it for if you are using a standard vulcanizer.

The mold frames in the pic are made similar to Castaldo U-Shaped Mold Frames For Room Temperature Vulcanizing Compounds, they can be found at RioGrande. The one with the nipple was purchased from Rio and the others were made with aluminum stock. I bent them with a metal bending brake and the corners bulged from the fold so I had to sand them flat.

Aluminum stock - www.lowes.com/pd/Steelworks-6-ft-x-0-5-in-Aluminum-Metal-Flat-Bar/3024784?

There are many low or no temperature silicone molding products available that can be cured in a common container. That may be the best for you.

If this info does not help please let me know more about your molding process and items.

Debra

A closing casting shop in the NYC jewelry district has a number of these for sale. Many other items as well. Let me know if interested.

Cliff

Hope it’s not to late. Any chance for the large frames at this late date?

They haven’t completely closed their shop as yet.

Are you anywhere near NYC?

Cliff

Pretty far, actually.

Oh well. There are some other ideas here to explore when I get around to it.

Thank you!

I don’t cast of make molds for vulcanizing and likely don’t know what I am talking about, but it seems to me that room temperature process molds could be cut from cellular PVC boards and plexiglass. You can buy the boards at Lowes. I have used them to make larger Delft clay casting frames. They work well as long as you don’t get the torch near them…Rob

One thing to consider. If you plan on silicone molds a mold frame used for vulcanizing rubber can’t be used for silicone.

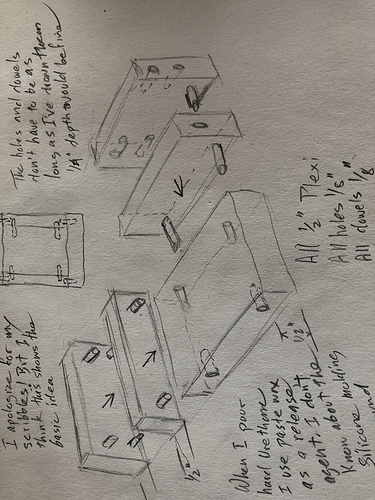

I cast hard urethane molds in plexiglass frames. I go to a local plexiglass supplier. They do lots of custom work and they have a “scrap bin” of pieces that are basically unusable for most applications. I usually find 1” - 6”wide pieces of 1/2” X 2 or 3’. I cut the bottom piece the size needed and make the 4 “walls”whatever height I need. I make the side walls for half the mold and another set twice that. I pour one half at a time. That would also be good if you’re going to do any powder separation molds. I use an 1/8” drill bit and 1/8” brazing rod from a welding supply to make

“alignment dowels”. I coat everything with paste wax as a release agent.

Could you please elaborate on the construction of these? I’m totally clueless

Thanks

Unfortunately I learned the hard way about the silicone and rubber a ways back

Unfortunately I’m a “go buy the solution, when I can’t figure it out kinda gal”. Could you explain more in detail the construction of this?

Thank you

Hi Elizabeth! I’m trying to finish up some buckles but I will make some sketches that will hopefully help you out. I have another person interested in making plexiglass mold frames so I’m putting this on the front burner!

That’s great. THank you.

I posted a question to a casting group on FB - mostly they do large non- jewelry type castings. Someone suggested I try Sorta-clear room temp liquid mold.

From what I can tell, it seems like a good option.

I’m now looking into finding plexiglass and how to cut or buy precut.

Sorta-clear has a video on making a plexiglass mold using a glue gun to connect the plexiglass edges (temporarily). I see another option of using plexiglass for the front and back and aluminum U shape for bottom and sides. Thanks to another Ganoksin user’s post above, they added info on how to do that. However, I don’t have the material to cut and bend it. I assume there are thinner aluminum pieces that would be easier - or maybe bought to size…Somewhere?

Sorry for the scribble. I think that you can tell what’s going on. If you have free lance machinist you could have this done in aluminum. You could do the low temp silicone compound then.

Drilling the holes I double everything up so that all the holes and dowels line up. I do the two sizes of sides - 1” and 1 1/2” so that I can pour

one half, then pour the second half on top. I’ll

send a couple of pictures of my hard urethane molds separately. Feel free to ask me any questions.