Hi Noel,

Here are some of my experiences, observations and opinions of white

gold.

Question 1. Flush setting in standard nickel white gold can be a

challenge. Nickel and gold alloys are usually hard and somewhat

brittle. Although there aren’t really any differences in procedure,

there is much less room for error in cutting the seat as you can’t

really move the metal around very much if you take just a hair too

much metal out. Flush setting in palladium white gold on the other

hand is not nearly so difficult and is actually a lot like setting in

yellow gold. The downside to the palladium alloys are their drab,

dirty gray-brown color and the challenges associated with casting.

Question 2. As you already know, there is no such thing as the

"perfect" metal. All have strengths and weaknesses. Any use of any

metal involves compromises, so I’m not really sure what you are

asking. It is very much possible to flush set sapphires in white

gold, I do it all the time. Just be sure to anneal the piece where

the stones will be set before setting. Soldering white gold can be a

challenge as well as it often develops a black, sooty firescale that

works better than yellow ochre at preventing solder from flowing.

Flux, flux and flux some more, heat up gently, flux it again, use a

very slightly reducing flame, and heat your solder pick a little bit

before you get it near the piece. If either one is appreciably colder

than the other, that fluffy black stuff will probably form. Once it’s

there, flux won’t flush it away, you will have to stop and clean it

all off before the solder will flow.

White gold will almost certainly wear much better than sterling, you

can use much thinner cross sections and achieve far more strength,

especially if fabricating. It is also possible to get a much higher

polish with white gold as compared with sterling. The finish will

last a lot longer too. It’s other main advantage is the profitability

you hinted at. Contrary to much of the public discourse these days,

profit is not a dirty word, imho.

There are a lot of different alloys for white gold. None are as

white as silver but some are whiter than others. If rhodium is part

of the equation, color doesn’t matter as much (until it starts

wearing off), but I hate rhodium and don’t use it unless a customer

insists. Stuller’s X-1 is popular, but I don’t have much luck with

it. I get porosity in almost every casting. It is like rock to forge

and cold-work. But it is white, which is about the only thing

positive I can say about it.

W.R. Cobb makes a nickel bearing white gold alloy for 14K and 18K

that is every bit as white as X-1, but is much easier to work with.

They call it “Precise White”, and it’s all I work with anymore. It

can be a challenge to cast with as well, but as long as a high flask

temp is used and the metal isn’t over-heated it works pretty well. I

use the same alloy to cast and fabricate with. The casting alloy

works very well for casting ingots and it rolls, draws and cold-works

remarkably well. I particularly like the warm, very slightly

off-white color of 18K Precise White for Gent’s wedding bands,

especially when a combination of matte and high-polished finishes

are employed. Well cut, E-F color diamonds really pop when set in it,

but don’t draw attention to it’s color as so often happens when

standard nickel or palladium white gold alloys are used.

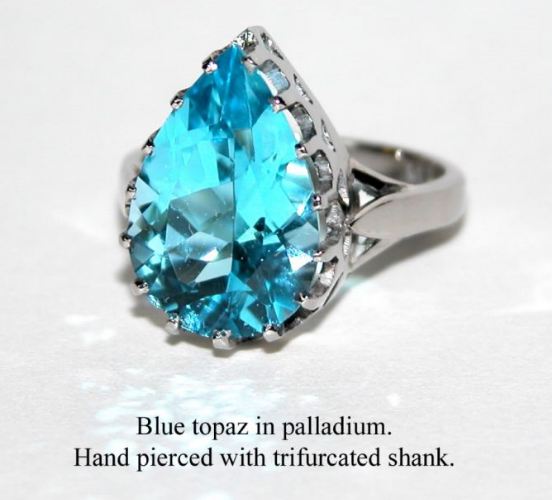

Palladium white gold is pretty easy to work with (for white gold),

but when cold-worked it work-hardens surprisingly quickly. Stone

setting with it (when annealed) is a lot like setting in yellow gold.

I understand it is possible to cast without ultra-high-tech

equipment, but I don’t have any experience casting it. I either send

it out for casting or far more often, buy 6X6 square wire and

fabricate with it, even when there is a lot of waste (I hate sending

anything out). It lasers OK, better than nickel white gold and a lot

better than silver, but not as easily as 14K yellow gold. It is also

hypoallergenic, which for those few people that are allergic to

nickel bearing alloys can be a huge deal. The one issue I have with

palladium white gold, especially 18K is its icky brownish gray color.

Not white, not warm, just icky. As to it’s long term wear

characteristics, I don’t have enough long-term experience to draw on

to give you a good answer, but my guess is that it will wear much

like yellow gold of the same karat.

Hope you find this helpful.

Dave Phelps