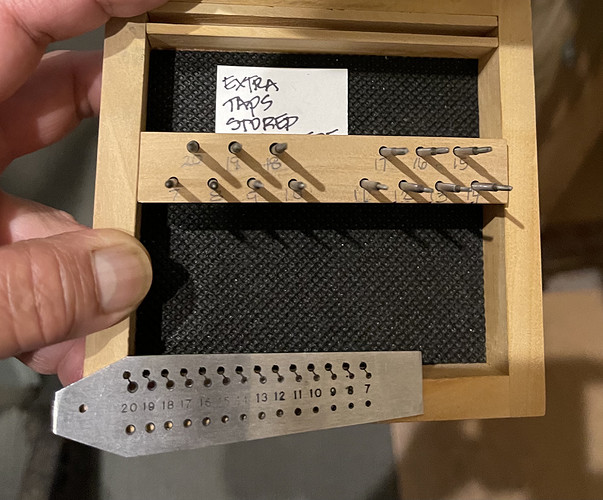

I am befuddled by this tap and die set. The dies and taps show .6, .8, 1, 1.2, 1.4, 1.6, 1.8 and 2 mm sizes. No instructions for this set, or any for taps and dies less than 1mm anywhere I have looked. This set was darned expensive and I would like to be able to use it.

When I use .81 argentium wire pulled down to .75 mm - taper the feed end at about a 30 degree angle and try to turn it, with a pin vice, into the .8mm die with cutting oil- it just chews the crap out of it (I know a real technical term.) The die also has 4- .8 mm holes - 2 with slots and 2 without- no indication if these are just redundant or are like that for a purpose.

Strangely, the .75mm wire will feed and cut visible threads in the 1 mm die- hard to image that is possible if the outer dimension of the 1 mm die is 1 mm (which is max diameter correct?) I assume that it is the thread cutting depth of the die that extends beyond .25 mm in the 1 mm hole that result in raised threads on the .75mm rod (wire.)

If anyone is using this set effectively or has an idea of how I am screwing this up or in what way I have it wrong- I would appreciate some help.

I’ve read that the drilled hole for the tap should be about 60 to 75% of the tap size. A 1mm tap would work with a .75 mm drill hole (actually a range between .6 and .75 mm.) I thought that the rod size for a 1mm die was suppose to be 1mm (the max diameter) but given that I couldn’t get a .75mm argentium wire to start and cut cleanly in a .8 mm die I have to question that.

Also, am I incorrect in assuming that I can cut these by hand- with the tap in a pin vice - carefully twisting it in to the drilled hole in the metal; and with the rod in a pin vice rotating it into the die (quarter turn etc, etc.)

Looking for a lot of good information on this- hope you can help.

Kirk