Some of my carved wax pieces did not come out well when they were

cast. I think the incising that I did was not deep enough, and I

would like to deepen the lines so that the patterns show up better,

whether oxidized or not. I have tried to work the lines but find the

metal too hard. What would be the best way to carve into the cast

silver? Should the piece be annealed? Whats best to use with the

flexible shaft? I’d appreciate any suggestions.

Sandra

Elegant Insects Jewelry

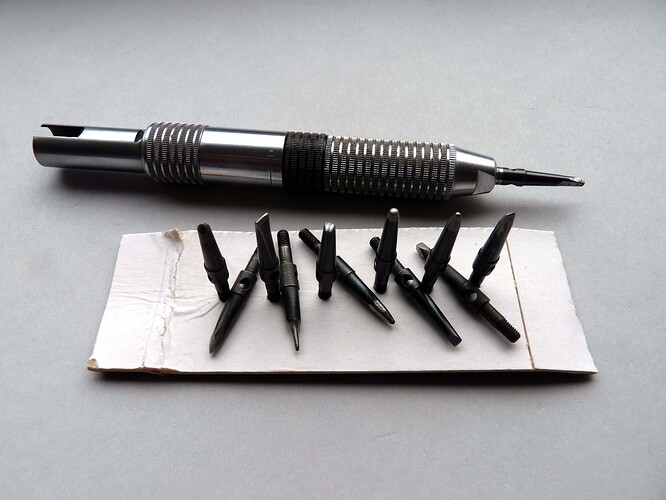

Hi Sandra, Castings that need textures and such sharpening up are

best done with chasing tools, for small castings I have also had

success at sharpening imagesby using a hammer head attachmenton my

flexshaft, I grind the removable hammerheads to the shapes of my

chasing tools. I have enclosed a photo of my hammerhead and shaed

hammerhead tools as an attachment, perhaps Hanuman will add it to

this note.

peace and good health to all

James Miller FIPG

Sandra,

I would get in touch with a master wax carver rather than try to

learn how to correct by carving into silver. Google Kate Wolf in

Portland, ME. She teaches in many locations including in Tucson and

ME. Kate is patience, practical and a master wax carving instructor.

Good luck,

Mary

Castings that need textures and such sharpening up are best done

with chasing tools, for small castings I have also had success at

sharpening imagesby using a hammer head attachmenton my flexshaft,

James is talking about chasing, which is a method of deformation -

moving and bending metal. Good advise… If you want to talk about

~carving~, there’s a pretty fundamental thing that’s kind of an

“AHA” moment for most. All carving is the same… Wood, stone,

shell, wax, metal, makes no difference in the end. Imagine a carving

of a dog or pick something else. That dog in all of those materials

is carved in almost exactly the same way (almost). The difference is

that you need to use material-specific tools - wood chisels for

wood, files for silver, probably wheels and grit for stone, unless

you’re doing hammer-and-chisel scale stone carving.

Beyond that, a good carver can carve anything - there’s just a

learning curve of how the specific tools differ. But that’s about

it. Carve your silver with silver tools - not wax tools - and it

will be fine. Or take up chasing, as James suggests.

would like to deepen the lines so that the patterns show up

better, but find the metal too hard. What would be the best way to

carve into the cast silver? Should the piece be annealed?

I’m not sure about the annealing actually but diamond burs, wheels,

knife edge discs or tungsten carbide burs carve silver well, some

pics

http://www.lascodiamond.com/products/tnt.htm

http://www.lascodiamond.com/products/discs.html

http://www.circofile.com/product2.html

I am not sure what your problem is. If the lines are filled in and

the fill material is rouge on the surface the investment in the

engraved lines broke away. Think of the investment that fills in the

lines of a wax model as dams. The investment in the engraved lines is

very thin and susceptible to breaking if the flow of the metal is too

strong.

Most all of my work has many lines all engraved close together and

at least one mil deep. Every now and then a line will fill in. This

occurs usually where ever the molten metal flow hit’s a line which is

next to a sprue. At this point the metal flow is the strongest.

Sprues must be placed so that the metal flow is not directed against

the engraved lines.

I use a Foredom hammer tool tip grounded to an engraving edge

mounted in a Foredom hammer tool to cut the fill material out of the

original engraved lines. It may take several passes to re-cut the

line as deep as the original.

The investment that was in the engraved line will be floating in the

mold. That broken off investment may cause damage to the model some

where down stream of the break off point. The investment may be

embedded in the casting on show up as a depression on the surface of

the model.

I am not sure it does any good but I shake all my flasks with the

sprue end down before placing them on the vacuum pump. I hope that

any loose investment will shaken out.

Lee Epperson