Hi Anna,

Since you intend to start with 6x6mm square wire to make 6x5mm wire

to make a bangle with inner circumference of 20cm you will need to do

2 calculations.

The first is to calculate the length of 6X5mm wire needed to make

the bangle. This is easy. Its simply 200 + 5x Pi = 200 + 15.7 =

215.7mm. (See below for the reason).

The second is due to the fact that when you roll the square wire

down to 5mm thick, it will get both longer and wider. I’ve created a

calculator at Rolling wire-strip calculator which will do

this for you.

Using the calculator, enter the required width, thickness, and

length of wire required:

That’s 6, 5, and 215.7 The calculator tells you that you should start

with 203mm of 5.6mm square wire, which can be made by rolling 180mm

of 6x6mm wire down to 5.6mm square.

So the process is:

-

Roll 180mm of 6mm square wire down to 5.6mm square. This gives

you 203mm of 5.6mm square.

-

Roll the 203mm of 5.6 square down to 5mm thick to end up with

215.7mm of 6x5mm wire.

-

Bend this into a ring and solder it up.

Here’s the reason for the 1st calculation.

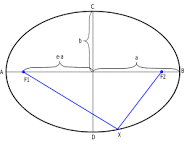

Imagine the stock that you want to bend into a circle to make a ring

is made of lots of very thin layers. When you bend it, the outside

layer is stretched and the inside layer is compressed. The layers

next to these extremes have to stretch or compress a little less, and

so on until you get to a layer near the middle that remains the same

length.

This layer is called the neutral layer.

It is convenient to assume that the neutral layer is in the middle.

To determine the length of stock needed, you simply have to

calculate the length of the neutral layer. This is equal to the

diameter of the neutral layer x Pi. The diameter of the neutral layer

is the inside diameter (call it ID) of the ring plus the thickness of

the stock (there is half the stock thickness on each end of the

inside diameter).

Therefore, the length of stock is…

(ID + stock_ thickness) x Pi. or ID x Pi + stock_ thickness x Pi

Because the inside_circumference = ID x Pi. The length of the

neutral layer is inside_circumference + stock_thickness x Pi.

I hope this makes sense.

Here’s hoping all my injuries and yours are minor!

Here’s hoping all my injuries and yours are minor!