I’m looking for any tips and favorite tools for polishing CAD created jewelry.

I’m having difficulty getting in to all the small and awkward spaces.

Thanks in advance!

A laser welder works great. You use a wide beam at low power to just barely liquify the surfaces, that gets rid of the grow lines leaving a smoother surface in hard to reach areas. The areas you can reach are just file, emery, abrasive wheel as you know. Then a magnetic tumbler will get a fairly uniform overall semi-finish. Then stiff or soft brushes with your preferred polishing compound on flex shaft as needed in those cracks and crevices or areas to be covered by stones. Then final polish after setting.

Contact Jason at Portland Jewelry Academy.

He finds out what works, and why it works.

He is extremely knowledgeable about how

to prevent issues.

He knows which printer and which resins.

I am ignorant about CAD-CAM, and I will

remain this way.

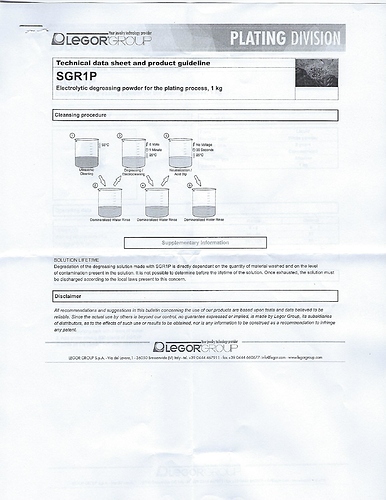

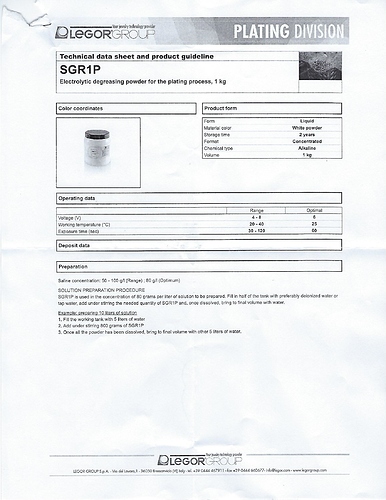

Enclosed is somethings I just this morning found for you and everyone!! It

gives the name for the solution to "Electro-Clean’ any item PRIOR to your

“Tripoli & Rouge” polishing.

Any “Magnetic-Tumbling” can be done afterwards. In my next few essays on

the CAD topic

I will show how intricate some of the projects I’ve worked on, but these

were ALL Electro-Cleaned first.

As this is an open forum, I had my tool supplier give me his printed

sheets for everyone to use…Hope that you find this information useful.

*Gerry Lewy *

Toronto.

Here are the two rather interesting solutions on how to “Electro-Clean”.

It’s all that I can offer.

*Gerry Lewy *

Toronto.

Hi,

A suggestion is that you could try dipping in procad solution before casting a resin piece. That will reduce the layer marks. Also cleaning the resin piece beforehand would be much more easier than cleaning a casted one.

Regards

Kartik