Hey Marek!

Sounds like a nice solution to the venting! Could you perhaps provide pictures of your steel tubing through the door insulation, would be much appreciated. Im a bit anxious about modifying my precious kiln, and especially taking apart the electronics and drill beneath the muffle!

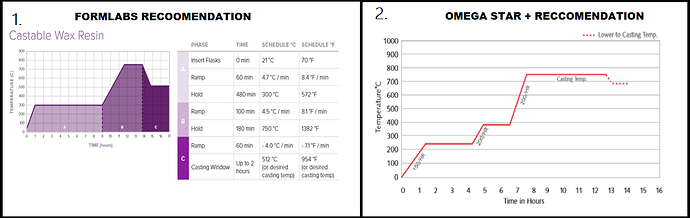

I too think i have exact the same problem as you had!! Whats the point of going directly from 200 c to 750 c? Burn the resin before it begins to messe with the investsment, but wont there come crackings in the investment instead?

Perhaps you would also provied detailed burnout schedule (c/h etc)?

Im getting decent casts, but not flawless, bit grainy texture and pitted spots here and there occationally…

I am using formlabs castable wax resin and using goldstar omega + burnout program

With regard to my workflow i should be doing everything after the book, but still getting these small flaws etc:

- If its a ash residue problem i should perhaps try with the open loop system or add more venting to my kiln which i am looking into…

- However, I tried to burn off three 3d models at reccomended top burnout temp, and I would say they burned out pretty clean with no residue as formlabs also promise with their material.

- I read online that the post cure of resin models is very important since uncured resin can interfere with the investment, especially in the vaccum… However my material should be ready directly after printing and rinsing… But will leave in my window shelf for bit UV curing anycase…

- If its an investment problem perhaps i should add more investment to harden 38/100 a bit more… I think i have enough worktime to do this… I usually get 2-3 cracks near my sprue buttom, maybe this tells a bit about it not being strong enough, or not proper burnout, even though im following the guidelines of Goldstar.

Best regards