Hey, I’m wondering if when you guys make boric acid and denatured alcohol, does the mixture mixed together or do they stay somewhat separate. Mine is not mixing and staying integrated. The boric acid falls out of solution.

Found this video:

Basically it naturally falls out of solution so I guess this is how it’s supposed to be. All good.

The chemists among us can tell you why, but the boric acid doesn’t dissolve, it just stays suspended. I keep mine in a tall sealed mason jar and give it a good shake before I use it…Rob

It dissolves in methyl alcohol but that is toxic and some people avoid using it for that reason. If you don’t get it on your skin and use good ventilation it won’t be that dangerous.

Brennan, boric acid is only slightly soluble in denatured ethyl alcohol, but a little dissolves, and the carry-over of the undissolved powder if you use a brush adds potency. It seems to me that larger lumps stain silver so I avoid that.

Boric acid is more soluble in methyl (wood) alcohol but that has safety concerns like spilling it on skin, breathing the vapors, so most people avoid using that.

Prips may be a better alternative.

It is not a solution. It is just a suspension of the borax in alcohol. It is never going to be a solution :). Just … shake it up before using ![]()

No kidding! Prips is easy to make and you probably can find instructions in the archives. The fancy commercial ones don’t seem to work much better. Just MY opinion now … alcohol on the bench scares me to no end. I have enough trouble not burning myself, let alone not setting the studio on fire. A borax cone and water go a long way if you are trying to prevent fire stain. On that matter, lather it up with what ever works for you, use a hot neutral flame and get in and get out. If you heat the damn thing all day nothing is going to help much. Once you start, never pull the flame from the piece, oxygen is your enemy. Have a torch that can provide enough heat. Temperature is not heat. Little butane torches get hot, but can’t put enough BTUs down on a piece of silver of any size, which as you well know just sucks the heat from the join :). Regardless, you still will some degree of fire scale. Buff it out or hide it with depletion guilding (which I think is unethical) you are always going to get some fire stain, it is just a matter of how much. Fire scale is that grayish mess that infilters your silver at high temps, fire scale is that black stuff on the surface which is easily remove by a good pickle. I moved to argentium, which has its own set of issues. Or you could just fire scale the hell out of it and call it handmade ![]()

5 years college chemistry here. Its about 30 years ago now. First to get the boric acid into solution it needs to be in a very hot liquid ie water. But for us we are using denatured alcohol. What happens when you heat the alcohol? it bursts into flame. similar to cooking with alcohol. best just to do as all have suggested, shake the container and you will be fine. Darn now I want some bananas Foster.

I guess my container is not airtight. I replace the alcohol when needed. Dip or dunk.

My problem is forgetting to close the lid when I am done using it. This represents a potentially serious safety violation as I could easily set the alcohol on fire with a stray motion of my torch. My goal is to try and overcome this habit…Rob

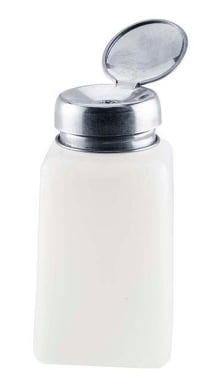

Rio sells a dispenser bottle with a lid:

https://www.riogrande.com/product/pump-dispenser-with-lid-7-oz/504033GP/?code=504033

You press the lid to pump flux into the lid’s top bowl. The description says it can be used with solvents. The pump does get gummed up when the flux dries, but it cleans up with a rinse in warm water.

I use an artists atomizer to spray Prips, a small squeeze bottle with a larger size hypodermic needle to apply Batterns type flux and an small paintbrush for handi flux or borax and water paste. I use them all along with alcohol and boric acid. My bench has been described by visitors as a chemistry set. I don’t know much about the chemistry but they all seem to have their place…Rob

Great big smile!

Be sure your not using borax powder use boric acid it works fine. Shake it up then dip your piece in it. After sitting for a long period it will separate, simply shake and reuse you should not have any clumps. I use it with sunny side brand denatured alcohol And BORIC ACID powder 1 to 1

I noticed that my usual sources of powered boric acid didn’t seem to be as powered as in the past. I was having similar issues until I started buying it from my local pharmacy. It is more expensive but it works well with both 70% and 90% alcohol.

Use Denatured Alcohol

I use Fuel Alcohol from Ace and Boric Acid from the drug store. It settles out in the jar and I have to shake it up.

I also tend to leave it uncovered as well. A genetic problem no doubt.

Don

Rob, I never could seem to find an atomizer that worked well with Prips. It’s tricky to put down, you gotta get the right heat going before you spray it and then do multiple coats. I’ve used the commercial fancy ones (like fire scoff) but really don’t see they have an advantage over Prips. I’ve found just slathering it down good with a borax cone in distilled water works about as well as anything. Silver is just gonna have some degree of fire scale regardless. It’s just matter of how much. I think flame control and getting in and the hell out with a neutral flame big enough to do the job is more important. Its why I only work with Argentium now, which its own set of issues.

Brent…I rarely use Prips, but when I do, I apply it with a cheap artist’s atomizer. Your comment regarding fire scale is my experience too. It happens! For me, the best thing to do it to know that It happens and do what I can to deal with it when it does and avoid it when I can. I use handiflux when doing heavy heating on large pieces and Batterns on smaller pieces. I coat with boric acid and alcohol prior to annealing and soldering pieces that have already had a pre polish prior to final soldering. Based on what I plan on doing with an ingot after it is poured and rolled, I may grind, sand, polish the whole rolled ingot removing any firescale prior to cutting or sawing it into smaller pieces to be made into earrings or pendants. This will keep you from thinning out and already thin area because you are trying to remove firescale. Finally, I may adjust the type of solder that I use, depending on how much stress a joint will experience, by using lower melting point solders when I can to avoid the fire scale that is produced. I always knew that I was creating firescale, but I never knew how much until I started using LEDs in my shop and looking at finished pieces in diffused sunlight. You can’t miss firescale under either of these conditions. It is humbling. I have been planning on trying Argentium or one of the other antiox alloys to see if I can avoid firescale a bit more, but I just keep on buying sterling silver. Old dogs and new tricks. More when I know it…Rob