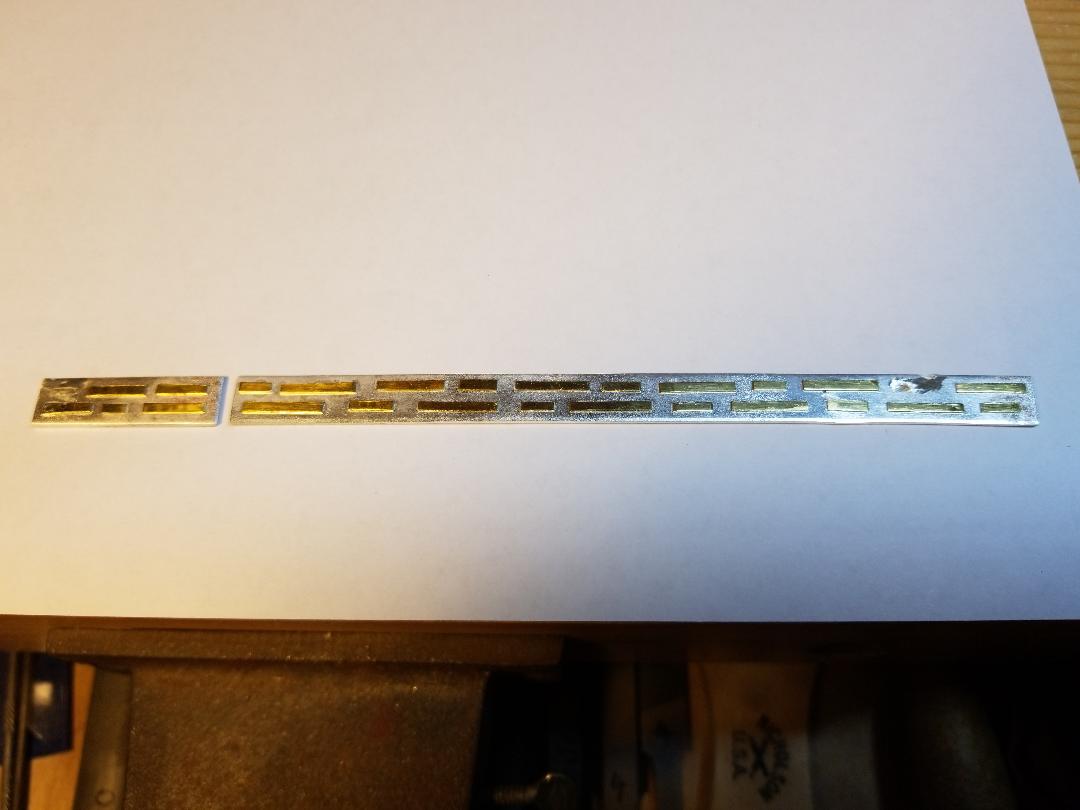

move them back into place but unfortunately only made it worse. I ground off the two mis-aligned gold pieces, one at each end of the bracelet and was thinking of fusing 2 new gold pieces in their place. But also at each end are small areas adjacent to the gold, where the Argentium “crumbled” slightly when I tried to move the gold. I set it aside for a day or so while I contemplated what to do. My questions are these. If I cut off the two bad ends and make two new good ends to match, can the new ends be butt-joined by fusing to the remaining good pieces? or should the new pieces be soldered to the good ends with MED or HARD Argentium solder? Would both joining process hold up to shaping around a bracelet mandrel? OR should I start over and keep the messed up parts for a ring and a pendant. Any advice is much appreciated.

I work with Argentium alot and have had the solder joints crack when applying pressure. I tried expanding small cone shaped pieces recently in a block, they cracked along the solder line after annealing. Argentium is prone to cracking in my experience, under slightly less than extreme working of the metal. I do love working with Argentium and know it’s limits. I would start over.

I would maybe try to cut the ends off, but then solder. You can’t really manipulate argentium at all when it is hot. No pressure on it either. It will crack or sort of mush. If you do start over, I’m sure you can make those pieces into something else beautiful!

Thanks for the replys on this. If anyone else has ideas feel free to share. Thank you.

I am a certified Argentium Silver Jeweler. I love this metal and have found it to have no limits whatsoever. However on this particular piece I would solder the ends together. If you file to get a perfect join before soldering with hard Argentium solder you should have a hard enough join to withstand the hammer blows. I would however not hit exactly on the seam, but just a slight bit off to the side, say .5mm on either side.

However you need to know that hard Argentium solder flows at nearly fusing temperature so you will be applying high heat to get it to flow.

The only thing to be cautious about Argentium is that when it has a tight surface tension (which happens at high heat) it will crack, so don’t touch. When applying embellishments I wick away excess flux so that the foaming up of the flux does not move pieces. Then I gently apply heat to see if they will move. If one does move, I stop turn off my torch then drop a tiny drop of water on that piece only and it will cause the sticky flux to release so that I can move the piece.

I dip that piece in flux, wich away and then re-apply heat. I never proceed to apply intense overall fusing heat until the flux has ‘grabbed’ my piece exactly where I want them. The best help there is to wick away excess flux.

I teach my students if you drop a drop of water on the piece and it balls up and ‘skitters’ then it is too hot. But if you drop a drop of water on it and it ‘sizzles’ it is fine to pick up and quench. “If it skitters - wait. If is sizzles - quench”

Thank you NJDesigns

What is “a certified Argentium Silver Jeweler”? Who certifies?

The Argentium Silver Guild in the UK.

I believe Ronda Coryell also has a certification series in the USA.