I HAVE AN UPDATE!

Long story short, it worked! I’ll try to walk you through the saga.

Step one was stone removal. I picked up a pair of evil looking pliers for the job.

I was able to pretty easily bend back two prongs and pull the stone.

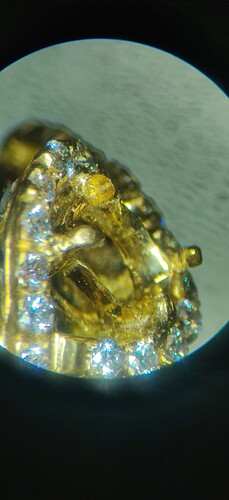

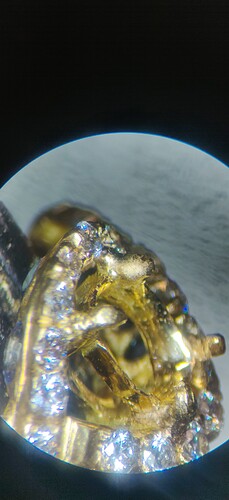

Next I drilled out the old prong. You can kinda see the hole.

Then I test fitted the wire:

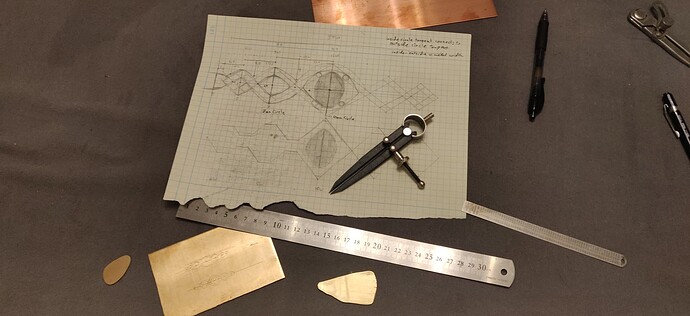

Them I clamped it all for soldering:

I used boric acid and denatured alcohol here. I’d paint a layer of the solution on everything and burn off the alcohol to leave behind the boric acid. I did this 3-4 times and then used a water dipped brush to remove any of the crystals from the sapphires.

First solder job was a failure. I got an initial rough connection and then got greedy and removed my clamp. Poof, the wire dropped out. Left behind a nice ball of solder. Oops.

So I re drilled the hole. Came out better the second time. Test fit, solder.

Solder flowed poorly the second round so I mostly managed an ugly tack. But it was enough to hold things in for round three. Third time a charm and all that I guess. Got a bit frisky with the heat here and balled the end of the wire. Oops again. Could have been worse, and it got me my prong!

Then it was grind and polish the seat, notch the prong, drop in the stone…and voila!

No damage to the sapphires and diamonds that I can see. Still more refining and polishing to do, but HEY, IT WORKED!

So I guess all that’s left is…

A HUGE THANK YOU for all the advice and encouragement! You guys really pulled me through here.

I’ll update here as I finish the ring and get ready to pop the question. You guys are amazing!

Happy fabricating!