Hello Janet, I use Cool Paste from Spain, which is applied to metal surrounding the area I want to protect from solder. Sounds like you need something to keep the heat away from your soldering joint. Another solution for very small areas is to get a syringe from a pharmacy, sand the end so that it is flat, not tapered. Melt it onto an extra torch tip, followed by two part epoxy glue to really seal the syringe to the tip; you don’t want to smell any gas. You would be amazed at how delicate a flame you can get from a syringe to really pinpoint one link on a chain, or other delicate places to solder! Syringes also come in a variety of hole sizes, and they are very inexpensive. When you want to change tips again, just unscrew the entire tip with the syringe on it. That will last for years.

Good luck,

Caroline

When i was young i roller skated often and i would always carry a tube of liquid graphite to keep the bearings loose and moving freely and to prevent them from locking up!!!

Yes a small amount of oil added to the graphite will “dirty” the metal just enough so the solder will not flow into the area of your hinges. You just need a small enough feather! Works like a charm! Good luck.

I’d probably use a needle in a handle of some sort. Pin Vice or even glued in a dowel. I’d flatten one side of the needle at the point and put a tiny amount where needed.

This sounds very interesting. I would love to try it but am a little confused about how it’s made.

When you say melt it onto a spare torch tip are you melting plastic? Doesn’t the glue and plastic melt when a flame passes through?

Thank you.

My best to all,

Lois

Hi Lois,

Push the plastic cone of the syringe over a brass torch tip that you do not use. I have a Hoke torch, if that helps to clarify things; those are pretty universal here among goldsmiths. They use either propane and oxygen or acetylene and oxygen. With a cigarette lighter, or any light flame, melt the plastic bottom end just enough to shape it around the brass torch tip. Since I could still smell gas coming from the joint when I opened the valves on the torch, I used 2 part epoxy to make sure the seal was good.

Then screw the entire tip onto the torch. Before you turn it on, you need to square off the end of the needle with a file or nail file; otherwise the flame will be crooked, since a syringe has an uneven end to penetrate the skin more easily (ugh!) When you light the end of the tip, it is gas that comes out of the metal rod of the syringe. The plastic does not get any heat at all. I can take a picture of mine to show you, but I won’t have time to follow through until the weekend.

Also, the heat resister that I mentioned was wrongly named! Sorry. It was late. It is called KARAT cool paste and it’s made in Spain.

Hope this helps and I will take pictures this weekend for you. I don’t have a cell phone so it is a process with digital camera, etc. to get a picture into the computer and send it.

Caroline

Thanks for your input but not really relevant  . As mentioned above, we’re talking about a distance of half a millimeter. If you have an area of a square millimeter, there’s no way to keep the heat away from half of it

. As mentioned above, we’re talking about a distance of half a millimeter. If you have an area of a square millimeter, there’s no way to keep the heat away from half of it  . Also, in general, for very small pieces, a large bushy flame is the best.

. Also, in general, for very small pieces, a large bushy flame is the best.

Janet in Jerusalem

Jo

Will pencil ‘stick’ to a highly polished surface (even if it’s clean)? These tiny soldered parts are usually places that you can’t really polish afterwards, so they need to be fully finished before soldering. In general, I find pencil doesn’t write well on metal (unless the surface is quite rough).

Janet

That is why I use a soft lead. It will leave tiny bits of graphite dust where as a hard one won’t.

Hi Caroline,

Thank you. I would love to see photos.

Best,

Lois

Hi Janetb,

Seems like everyone love a bit of grease and you like to have the part all prepolished as there isn’t space for post-polishing!!

From experience it seems that anything that is added to a basic flux raised the flow temperature of solder.

There is an alternative to add to the topic. That is to use a scorper so that any excess solder will run away

into that sacrificial grove. This is good for hinge work and with a bit if training you can remove the pieces of chinner in between the pieces that you are soldering. Graphite pencil leads are good for keeping chinner straight during the process if needed,

Sorry if this isn’t your exact answer but it may help others?

Hi Janet

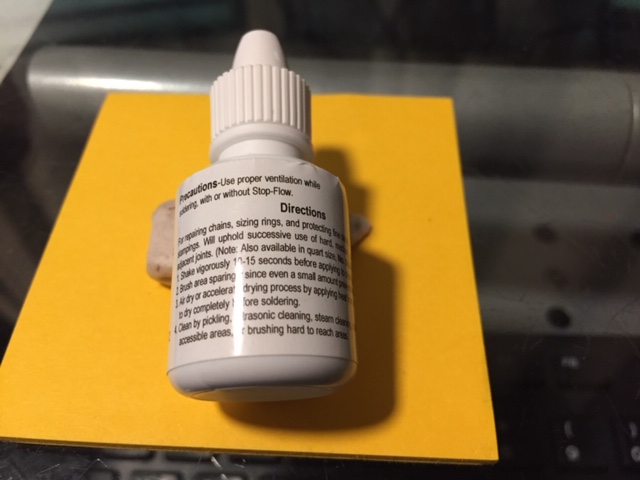

Here are a couple of pics what I use. Don’t know if you can get where you are.

I shake well then apply with a very fine brush. It is very fluid and will run into hinges or other areas where you don’t want solder. After applying I heat lightly to set, then apply boric acid/ alcohol and flame off then flux area to be soldered. Works pretty well. The green material appears to be very similar to Rio’s pens but I have much better control of application with this method.

Cheers

Franz