Sodium Bi-sulfate, that’s what I use. Other than teaching it 52 years ago as a sub, I don’t know anything about chemistry. I just know that pH down works for me…Rob

Hi,

i put the ingot into the hot water and wss surprised at how clean it was when it came out…then taking advantage of this clean starting point, i then put it into the pickle so that i could clearly see the effect the pickle had on it…and then in to the baking soda to see its effect after…coming straight form the pickle…i wanted to photo document the effects…

i am liking the hot water pre-pickle step…since i use prips flux, the metal is usually oxide free, and just has flux that needs to be cleaned off…if this is the case i can skip the pickle step…

julie

biochem has advanced incredibly since then… studied it in the 1970’s… keeping up is another thing!

The general consensus seems to favor sodium bisulfate. It’s cheap, less dangerous than sulfuric acid and is EFFECTIVE…I would recommend using it or a cleaner/acidifying household product containing it.

Sulfate acids (sulfuric acid, sodium bisulfate) do not react with silver except to leave a microscopically thin layer of fine silver on the surface…I haven’t used anything but soidum bisulfate…do not use any other mineral acids… hydrochloric acid will slowly dissolve silver…leaving silver chloride…nitric acid will dissolve it completely…if that ever happened to anyone, all is not lost… silver chloride will revert to metallic silver when heated, with the caution that chlorine gas will be driven off… dissolved silver in nitric acid can be recovered by putting a copper coil in the solution… pure silver crystals will grow on the copper as the copper gets dissolved by the acid…the solution will turn blue due to copper entering the solution…but the yield will be low… can’t recover all of the silver.

There are some inaccuracies here.

Silver do not dissolve in HCl per se, but a thin layer on the surface will convert to AgCl.

Nitric will dissolve it all , given enough time which will destroy the item.

Warm Aqua Regia can hold a minute amount of AgCl dissolved but not much.

Cementing on Copper will in all practical sense recover it all,

at a purity of 98-99.9 depending on washing and cementing techniques used.

Heating AgCl will convert it back to metal,

but not without losses and it should be done in a bicarbonate flux.

And as we say in the Gold Refining Forum, GRF, if you do not throw it away it is never lost.

made a mistake in deleting posts… you are absolutely right… I have a couple of pounds of gold plated fine silver used and discarded but clean medical electrodes… I did try to separate the gold from the silver as an experiment… I dissolved the silver with a mild HCL/HNO3 solution… the gold plating was left intact but was too thin to pick out without breaking it into pieces…the silver was recovered by adding salt, turning it into silver chloride… but that’s as far as I got… the particles in the precipitate of AgCL were too small and passsed thru a coffee filter… a millipore filter might have worked, but that was the end of it… the cost of reagents and fine meshed filters would have been totally cost ineffective in recovering the gold… the gold plating was so thin that it could have taken a couple of hundred pounds of electrodes to get an ounce of gold…the best that I could do was to melt it down for fine silver ingots to roll out for bezel making and wires…the trace amount of gold was inconsequential…It proves that chemical methods of separating metals does work, but only in bulk and is cost prohibitive.

You would have been better off using plain dilute Nitric since it will not touch the Gold plating.

Any strength Aqua Regia will dissolve some of the Gold and not touch the Silver much at all.

If you used weak AR there will not be much Silver at all.

We use two techniques to remove AgCl from a solution of hot AR.

One, dilute it so it can’t hold much Silver and cool it with ice so it can hold even less.

This is often done at the same time.

The Silver Chloride can be smelted with bicarbonate flux with losses.

Converted with Lye and Sugar or converted with Sulfuric and Iron.

It doesn’t pay to use this on merely a couple of grams and

the Silver Chloride need to be kept wet at all times.

We have members in GRF which claim to have reached 999+ pure Silver with cementing on Copper.

Good technique and good timing is required, but 99 is quite easy.

Hi,

i have used sparex in the past…but my last batch was a weird tan color and left a weird scum in my pickle…so i got rid of it…and

i decided to try the foid grade citrus acid based Pickle-It, since it sounded “safer”

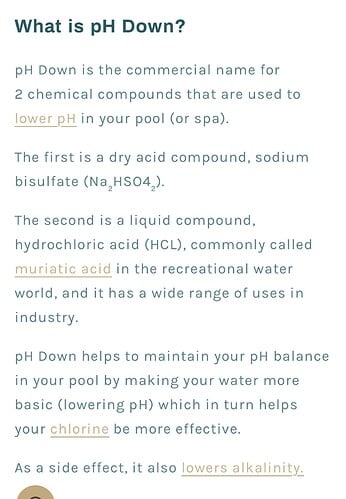

regarding PH down, i was researching it the other day and it seems there are two types (for pool use)…

sodium bisulfate

hydrochloric acid (muriatic acid)

i may try sodium bisulfate PH down later, as it seems to be the pickle ingredient…are see if it is sold separately somewhere

julie

You might try a high percentage vinegar if you don’t want to use pH down. I buy 20% or higher to kill the weeds in my garden…Rob

Thanks. I sometimes get so tired of folks saying “Well I’ve never done this but I’ve heard that …”

My late mother born in 1917 was a female pioneer chemist. She taught us to always research and verify any and all information. Especially when it was in the news paper, (remember those?) or on TV.

Jo

the gold did separate from the silver which did dissolve. the amount of gold on a single plating was like thin gold leaf with a 10mm diameter… could have picked it up with a scoop but it tried to with a tooth pick which broke it apart. The amount of gold wasn’t worth trying to extract…The silver was completely precipitated out of solution by the addition of plain table salt… it formed silver chloride but the precipitate was of such fine particle size that it could not be filtered using just a coffee filter… Don’t know how to get it to stick together in biggers particles that will catch…maybe the solution was too dilute. I’ve seen some videos where the silver chloride is like cheese curd… There’s several ways to chemically purify silver. Most of the commercial refiners are using “fire refining” which is injecting oxygen into molten silver alloys with copper and zinc, and basically burning them out… I have done that using an oxyacetylene cutting torch head… had to use a lot of flux which turned brown from the copper oxide… what I got was “spitting silver”… fine silver adsorbs 20X it’s volumn in oxygen, as it cools, large bubbles of oxygen exsolve, “spitting”… a bit dangerous as it can throw out droplets of red hot metal…if the metal is cooled slowly, silver oxide will revert to silver metal…it can’t remove the gold, which is inert… with the medical electrodes, I don’t see any economical way to recover such small amounts of gold… unless it’s processed in large quantities commercially… I’m just fortunate to get a free supply of fine silver plated with a trace amount of gold…normally, they would have just tossed them out but I asked them to save it for me…

eventually I’m just going to send all of my silver to a refiner and have them return it as investment grade silver bullion. I;ll lose some money on the fees and markup for bullion, it but it’s worth it, since most of the silver scrap was acquired at $2.50 an ounce years ago… that’s besides the electrodes… althogther about 20 or 30 lbs of it…at least bullion will be liquid… scrap isn’t…

evrything that you say is right… but there are a lot of different ways to separate metals… the oldest was cupulation…

Woohoo! Hey Nancy! Love your channel! Been watching you for years!

Have a wonderful day and God bless!

I agree on just using straight citric acid.

I used sodium bisulfate for at least 45 years. I ran out, had some citric acid and tried that. I’ve been a convert since then! I wouldn’t buy a proprietary product that’s almost straight citric acid at an inflated price.

Boric acid and alcohol works great for soldering but not for melting metal to pour ingots. Make sure that your crucible is properly coated and use borax to help absorb oxides.

Hi Phil, do you use a particular brand that you are happy with?

…should it be “food grade”…? or doesnt need to be…?

thanks!

julie

great question: citric acid from a chemical supply store or something off the shelf in a pharmacy or supermarket?

Hi folks,

I want to add extra amount of caution on the subject of ACID!!!

Especially NITRIC and Sulfuric.

If you’re dealing with C.P (100%)

You are putting your eyes, lungs, life at risk and to a lesser degree your tools. There are much safer options that have been discussed here at length. Educate yourself thoroughly before you attempt anything as volatile as this stuff.

Thanks,

STEVEN

don’t use hydrochloric acid based pH adjusters… chloride has the potential to make silver chloride… use NaHS04 based…sulfate doesn’t react appreciably with silver…then stick to what is familiar, cheap and works the best you… too bad they had to reformulate saniflush… used it exclusively until they got rid of the old formula and had to switch to sulfuric acid… reagent grade sodium bisulfate is expensive also…may try swimming poor acidifier as you mentioned… with the sodium bisulfate based formula.

can’t agree more… maximum concentrated nitric acid (68 weight percent) fumes clear or red gas, gaseous nitric acid… reaction with metals causes exsolution of N02, a brown corrosive acid gas…and NO, also corrosive … all gases fumed by the acid and its reactions are toxic and corrosive…maximum concentrated muriatic acid is saturated hydrogen chloride in water at 37 weight % …it will also fume HCl gas as which is corrosive… it differs from pure clear, HCl acid in that the yellow color of muriatic acid is due to ferrous iron impurity… concentrated sulfuric acid is anhydrous… it has no free water…adding water to concentrated sulfuric acid will result in a heat of hydration which is a violent reaction that will cause water to flash into steam and splash back explosively…even glacial acetic acid (highly concentrated, anhydrous, white vinegar, essentially) will hydrate with evolution of a lot of heat…sufficient enough to burn or even boil and also flash back…

Never add water to acid when diluting it… always add concentrated acid to water SLOWLY, stirring with a glass rod…the solution will still get hot… make enough dilute acid to store, so you won’t need to make more soon…keep it shielded from sunlight or other bright light (nitric acid turns yellow or brown with strong light due to decomposition into NO2, and tightly sealed in a proper container appropriate to the acid (glass is the best for nitric, cross linked polyethylene plastic bottle slowly degrade)… Do not store it with organic acids like citric or acetic… a strong oxidizer like nitric could cause combustion when mixed). HCl acid can be stored in polypropylene bottles… use the bottle that it came in when ever possible!..concentrated sulfuric acid can be stored in Teflon or polyethylene bottles.

No one should be messing around with hydrofluoric acid. Once used in the decorative arts for etching and frosting of crystal, both crystal glass and quartz rock crystal, and other silicate minerals and gems, is no longer used for that purpose… it is far too corrosive and toxic for anyone to deal with… spilled HF can have it’s acidity neutralized by alkali, such as baking soda, but the fluoride ion causes painless or painful tissue death that is a toxic and not an acid effect. HF burns are a medical emergency as painless tissue destruction continues after the acidity is neutralized… the fluoride ion kills cells by blocking cellular respiration (oxygen utilization)… first aid treatment is by flushing with large amounts water in a shower and removing all contaminated clothing, better all, and discarding without touching any wet areas… if available, apply calcium gluconate gel (not available!) or a paste made of crushed calcium carbonate (tums or equivalent) to all burn areas extending way beyond the burn, until the ambulance arrives…

Every concentrated acid is extremely dangerous including organic acids such as concentrated vinegar acid; diluted acids are still dangerous. Hydrofluoric acid has no place in home or studio, and is reserved only for controlled industrial applications. Nitric acid is a strong oxidizer that burns tissue beyond its acidity…

Household use of acids beyond their use as pickle can make cleaning easier if done with caution… HCl acid is in toilet bowl cleaner. The ring around the bowl is hard water deposits filled with bacteria… Muriatic acid will dissolve hard water deposits quickly, kill bacteria but also is corrosive to old cast iron sewer pipes… if you still have cast iron pipes, flush multiple times to wash away the acid…it also can be neutralized with washing soda more effectively and with less fizz than with baking soda. I would not use it in the bathtub… citric acid does well and is the active ingredient in Lime-Off. It can be combined with a detergent such as dishwasher soap for better cleaning of bath tub rings and soap scum deposits…

one final caveat: don’t ever mix acid or ammonia (not an acid, but highly alkaline) with bleach to clean anything… acids cause bleach to decompose into chlorine gas, a corrosive gaseous poison…

I just grab it off the shelf in the canning section at Walmart. I just ordered 20# on Amazon. Just make sure that it’s just citric acid with no additives.