I have a bum thumb. I need a tool to hold an item while I work with the good hand. Polishing and hard pressure. Not a third hand for soldering.

A search for “thumb brace” on Amazon results in multiple alternatives, but you probably are aware of that. Would it be possible to work with an orthopedic specialist to fashion brace so that force applied to the thumb would be transferred to your wrist?

Or, do think an engraving ball/block would work?

Hi,

at first I thought about a jewelers clamp, basic, durable, inexpensive…but that is handheld and still requires grip strength…

then i thought about the Knew Concepts guillotine clamp, but again this is handheld and requires some grip strength…

it would seem tome that you need something that is stablized (clamped down) and provides resistance to your good hand, without needing grip strength…

then i thought about a Panavise…they come screw in, or a suction type bottom…it rotates on a ball…i have mine screwed onto a piece of wood, that I then secure with a C-clamp…this requires a lower benchtop and is possibly less easily maneuverable…

then i thought about a benchmate system…the system is offered in a few different accessory packages…pricey, but could be considered worth it…

then i thought about a ball vice…again, pricey…GRS sells micro, microXL, regular, etc…all diferent weights/ heights…see their youtube chanel for informative videos comparing the sizes

micro blockXL is still weighty enough, while being small for under the scope

the standard block is nice and heavy…

the benchmate and ball vice will probably require less hand strength from you…the benchmate is docked onto a dovetail bracket on the bench edge, and the standard ball vice is heavy and stable… they all have attachments suited to different needs…

if price is not at object, i would suggest the standard ball vice, or benchmate qcx…newer bracket…stays centered…you hold onto the ring clamp, or…lock it down in a particular position

for both the benchmate and ball vise, you can tighten or loosen the tension on how much it turns/ rotates/ spins/ etc

Julie

I have the GRS Benchmate and 5” engraving ball as well as an economy ball. They all do a great job at holding objects securely. If I had to choose only one it’d be the GRS ball vice. It offers more versatility as it can hold items flat for setting/engraving and items can be held upright between the jaws for filing/finishing. It can also be used for setting with additional attachments. The upper section can rotate freely or be locked in place. Its plenty heavy so it stays in place, But this could be a plus or minus depending upon one’s challenges.

If filing/ finishing is your primary focus then the Benchmate is a fantastic tool. As Julie

said, it uses the mounting plate to attach to your bench. It stays securely in place and is easily maneuverable. I prefer the original version to the newer setters arm setup, but the quick change inserts are pretty sweet.

If you decide to purchase a GRS tool, you might want to keep an eye on Rios’s used tools. I snapped up a like new Stone Setters Benchmate for $200 off. There are also a couple of tool destashing groups on Facebook.

Good luck!

Pam

Hi,

the ball vise, being s rounded profile, allows you to hold/ manuver it with a more open/ less clenched grip…the larger standard ball vice has a bigger ball and taller jaws

the microblock. xl is approx 7lbs

the standard block is approx 21lbs

(being 20+ lbs, the standard ball offers a more solid “deadblow” resistance…the benchmate is a bit “bouncier”)

there are attachments for the blocks, as well as Jura attachments and Alexandre Stone Setting attachment packages…vise jaws with pins, shellac plates…etc

the benchmate also has attachments…

if you prefer working at a benchpin, i would venture to suggest the benchmate…and you can quickly switch out to other dovetail mounted helpers…like a benchpin, metal piercing pin, height adjustment plates, metal vise shelves, third hand soldering stations, et

the benchmate qcx, in addition to maintaining a rotationsl center, also has the added benefit of being able to flip the ring holder upside down to gain access to underneath the ring head…ie: lets say you were setting a very large cabochon with a scrolly under gallery/ basket and you wanted to file or thrum that…it allows for that rotation, whereas the ball vice will only tilt around 90 degrees

the ball vise accomodates flat better, like if you sre engraving ir stamping flat pieces…the flat top of the vise offers more support

(if you have an older benchmate, and want the centering ability, you can just order the qcx bracket

what kind of work do you do? that might determine the best fit…

julie

I have multiply braces, but they prevent me from gripping hard enough. I would hate to push the problem up to my wrist. I will look into the engraving ball/block. I believe I have one from my late father. Thanks.

Wow, thank you Julie. I a lot of good options to explore. Very much appreciated.

Pam, thank you. I will look into these options. I need to dig through my late father’s tool. He was a hoarder and I know he must have something. Susan

Hi,

how lucky! tool hoarders are among my favorite people!

julie

HI,

I forgot to add…you can first use thermo-loc to make “fixtures” to “hold” the piece…and then hold the fixture firmly with the vise jaws of the ball vise or the benchmate ring holder…you can put saran wrap around object before thermo-loc for easier release in 2-part fixtures…

or you can solder on a temporary rod, to hold in vise clamp/ ball vise/ benchmate

or you can shellac it onto a short dowel, to hold in vise clamp/ ball vise/ benchmate

itty bitty pieces are such a challenge to hold!

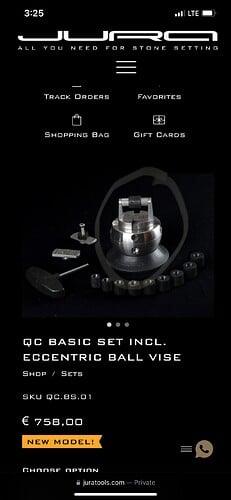

i am thinking of picking up these Jura fixtures (sale!) (not sure how long this particular Jura system will continue to be available…)

(i think the groove in this fixture is too big for an earring post, but i can put a flat surface of thermo loc on one side, or…

julie

Thanks Julie. What do these two items attach to? Probably a novice question.

I am not sure what your budget is, but take a look at a small machinist vise. You can find them fairly inexpensively at a Lowes or similar store. You might want to add a protective layer of copper to the jaws.You can also buy small vise’s that are hand held and work a lot like a large pin vise. Smaller pin vise’s might also be of some help. This may already have been mentioned, but there are several different thermo-plastic materials that you can buy that will hold your work either by themselves or in a vise of some sort. They include Thermoloc, Jet Set, dopping wax, chasing pitch and you might even secure a small piece with super glue. I use a nail or brass rod and then carefully heat the nail or rod to release the glue. Good luck…Rob

Hi,

so the Jura system…starts with a jaw adaptor…then the attachments fit on that…

julie

Hi,

the adaptors (circled)

fits on grs micro balls

(replaces micro ball jaws)

and on grs standard balls

(fits on top of the standard vise jaws)

kinda looks like this…then attachments slide in…like the football goal post arms show here, which then hold some of the attachments

julie

hi,

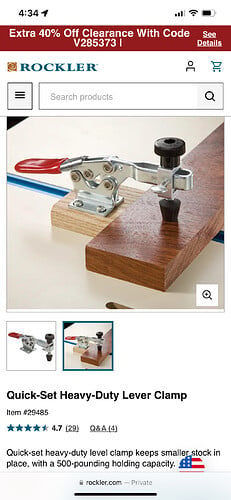

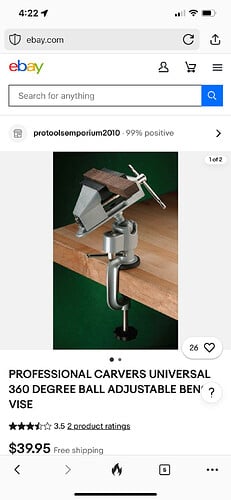

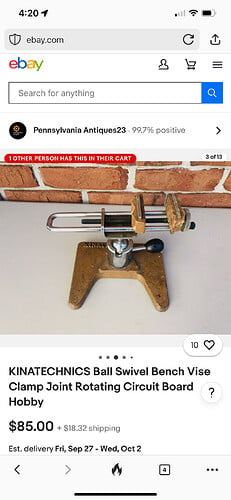

search bench vise clamp on ball joint, etc

here is one with an interesting articulation…could possibly mount it somehow on the front of bench…perhaps screw into a block of wood which is then clamped onto bench top…

Hi,

i feel like important features would be easy/ quick release type, small vise jaws…and good clearance for filing etc…

Wow! These are some great options. Thank you so much. My thumb thanks you also;

Thank you. Copper will protect the precious metal from the vise?

I am only suggesting that if you use a machinist vise with a tooth pattern on the inside. Typical jewelers bench vises and engraving balls have smooth steel jaw face surfaces. I still have copper shields ready for my bench vise just in case I am worried that the steel vise jaw face might cause damage to a delicate surface. My bench vise is very old and the top surface is damaged from file and saw slips. This tends to leave raise areas that might damage a piece being held in it. I take it apart and smooth off these surfaces once in a while but they eventually return…Rob

Hi,

another way to protect your metal is to use leather pads…ie: cut from an old belt…from a thrift shop perhaps.

i buy mine from GRS

and!..my sister got me magnetic vise jaw pads for christmas last year!..for my bench vise.

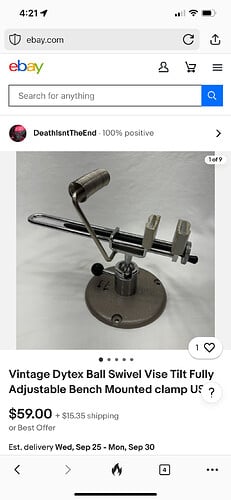

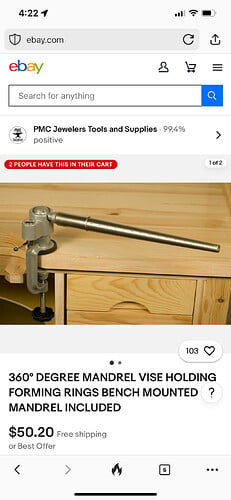

maybe she will get me this! this year! haha!

i have coveted this for years…i made my own out of wood, wing nuts, and C-clamps!

julie