Hello everyone,

Although I’ve been following this forum for ages, I just joined the group.

I’m having some trouble “reading” my acid testing results for gold content.

What I have:

- Box of acid tests from Technoflux,

- Touchstone,

- Sample touch needle from Cookson.

Since the first time, I tried to use this I was confused!

I originally bought only the testing acids and the touchstone, there wasn’t a sample needle available then, so I bought it recently in hopes of understanding what I was doing wrong before.

Unfortunately, I still can’t figure out if I’m doing something wrong or if the acids are not good.

I followed the instructions on the GIA website for acid testing, sanding the touchstone before cleaning any residual gold from previous attempts, and having two cups, one with water and soda bicarbonate and the other with water.

GIA - Acid Test

Testing:

- 1 piece of gold from a piece of jewellery that was hallmarked at the assay office as 18k.

- 8k sample needle;

- 10k sample needle;

- 14k sample needle;

- 18k sample needle;

Acids:

- 9k

- 14k

- 18k

- 19.2k

- 22/24k

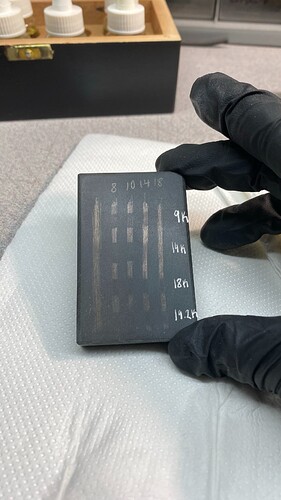

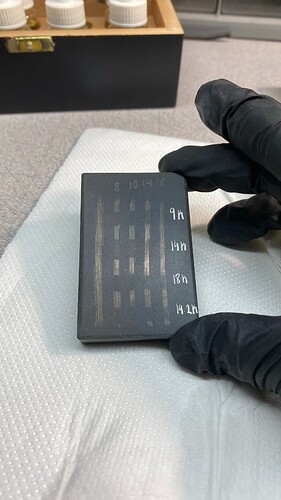

The carats you see written on the top are the sample needle carats; the ones written on the right, in white, are the testing acid carats.

My questions are:

- Why would the 9k acid remove the 10k sample?

- Why does the 9k acid have a stronger mark on the 14k sample than the 14k acid? If you see it from a different angle like in picture 3 the 9k acid removed the 14k sample!

- Why does the 18k acid do more to remove the 18k sample, than the 19.2k? Shouldn’t it be the other way around?

- Lastly, but most importantly, why didn’t any of the acids remove anything from my gold sample that was hallmarked at the assay office as 18k??!

I’m wondering if I did anything wrong, if the acids are wrong, if the samples aren’t correct, or if it’s just me not reading this correctly?!

I honestly don’t know what to think about these results.

I would much appreciate it if any of you would elucidate me.

Thanks in advance!

Kind regards,

Catarina

1 Like

I’m so sorry, but I’m no help with this question. I’ve never had good luck with reading karat acid testers. I used to work in a jewelry store with this system. While I never got consistent results, the owner of the store always made it work.

This system has been around many years, so hopefully someone in the forum can help you out!

Eventually, for my own work I bought an electronic tester, which is a lot simpler to use and that I like a lot.

All the best!

Jeff

2 Likes

Hi Catarina,

Yes! You have an inconclusive mess. I use these acids a lot of the time, and you always have to question the acids.

Sometimes, brand-new acid I bought did not react at all as it was supposed to. I would get another set of acids from someone else and compare.

Maybe in six months, the ones you have, will be more accurate. (?) I have been told they have a six-month shelf life, (I’m not sure if that is true), so unfortunately they are untrustworthy. Furthermore, I get good acids that react as they should, about 60% of the time. Right now I need to buy a new 10K because it reacts like water! I’m glad they are relatively cheap.

The thing is to compare the reaction with the piece you are testing, with the reaction of the test needle reaction. Don’t worry about the acids being correct, so much as comparing the reaction to the piece you are testing.

Mark your test stone with the piece and the test needle next to each other, and then run the acid on them at the same time and watch the reaction.

Maybe mark your scratches a little deeper. Press down a bit more so you can compare the reactions on more material, until you get the hang of it. But it looks good to me what you did.

By the way, what is the first scratch on the left, on the test stone?

A couple of years ago, 15yrs?, I bought a gold tester with the gel pen. At that point I was only testing gold once a month and the gel kept drying out even when I bag it. So I gave up on it. I think the new ones maybe better.

There is an acid that is used, (nitric?) that does the same thing except that it is one strength and watching the comparison on the lower karats was too hard for me. I know jewelers use this method a lot, so I was probably not doing it correctly. Maybe someone can tell us how that is supposed to go? Please?

I really hope this helps you! A bit long-winded this morning.

Best always.

3 Likes

Thank you Jeff for your reply and for sharing your own experience.

I’m intrigued by the electronic tester you talk about, I will investigate it further!

Thanks for the suggestion

Hey Rambalyn,

Thank you so much for sharing your knowledge and your thoughts!

This is a mess indeed! My acids have been more than one year now, I thought they’d gone bad, but honestly, I don’t know. I wish these kits came with clear instructions and a way to test if the acids are good or not.

I’m going to try them again soon, and if I have different results I’ll post them here for the update.

The scratch on the left is from a bit of a gold ring that was tested and hallmarked as 18k, and it doesn’t react to any of the acids! I really don’t understand any of it.

Honestly reflecting upon the electronic tester Jeff talked about!

Thank you so much for your reply, and for sharing your thoughts with me. Truly appreciate it!

Wish you a lovely end of the week

This the metal tester that I use. It’s expensive, but it works well & it’s easy to use. Most jewelry tool companies sell it. And you can get it on Amazon too.

Best of luck sorting this out!!

Jeff

1 Like

Testing gold with acids has been used since antiquity. It is however easy to get confusing results. The variables include the type, concentration, purity, and combination of acid; the metal alloy being tested: the temperature o the testing environment; and the length of time of the test.

Nitric acid is the main ingredient in the testing soup, but not very useful alone, so it is mixed with hydrochloric acid to make aqua regia which is used to dissolve gold. Neither nitric acid (HNO3) or hydrochloric acid (HCl) can do this alone. HNO3 will act as the oxidizer and is used to form gold ions (Au3+). The HCl is then used to react with the gold ions to form tetrachloroaurate(III) anions which are soluble in that acid solution.

The acid concentrations determine how aggressive the solution reacts with the target metal. If the acid is old and has lost some of the HCl or HNO3 by evaporation, this changes the reactivity. The purity of the target metal alloy will also affect reactivity. Nitric acid does not react to gold that’s 12 karats and above, nor does it react to stainless steel, zinc, tungsten, aluminum, platinum, or palladium. Also if the gold is alloyed with platinum, or palladium to make a white gold, you will get strange results.

Here is a web recipe for testing solutions (I have not tried them):

10K - 3/4 ounce, by volume, nitric acid - 1/4 ounce distilled water

14K - 4/5 ounce nitric acid - 1/5 ounce dist. water - 10 drops of hydrochloric acid

18K - 1/5 ounce nitric acid - 1/5 ounce dist. water - 3/5 ounce hydrochloric acid

Now lets take a look a a simple case of 14 K red gold, an alloy of gold and copper. If the test solution is old or the room is very cold, the 14K solution is not going to work. How do we know if the solution is good? You use a known purity of gold as a control. You do steak test with the known control and the sample and as time passes you compare the reactions of both streaks. Or better yet streak with known 10,14 and 18K samples. You watch how long it takes to attack the streak compared to the known samples. With a bit of practice, you can just use one high strength aqua regia and watch the reaction. This still can be confused my alloys that contain other noble metals like palladium.

I hope this is of some help and welcome corrections.

3 Likes

acid streak testing is not only an ancient technique but also one that is extremely difficult to interpret unless you do it often and use controls to calibrate. There are too many uncontrolled variables that make this technique difficutl… it’s more a screening test to detect low karat gold or other precious metals, rather than a quantitative technique. These’s also experience and subjectivity in interpreting the results. Pawn shops used to use this technique but it’s long been supplanted by electronic testing. It’s not something that I would rely on, other than screening.

See below on how electronic testers work. it’s based on the electrical conductivity of the metal being tested. Although I’m not absolutely sure, the computed algorithms should also have to take into account the capacitance of the metal.

Gold Testing – Electronic - Portland Gold Buyers, LLC.

2 Likes

Thank you so much.

I’m going to see if I find it here, or if I’m ordering it from some online shop. I’m sensing it’s my best option, although it’s a bit pricey I’m sure it’s worth it.

2 Likes

Hydrochloric acid does react with stainless steel… Nitric acid doesn’t… I had some animal water bowls made out of stainless steel that got hardwater rings build up on the inside…I used HCl to clean it and it blackened stainless steel…chloride removes chromium oxide which keeps stainless steel stainless…just a caution… otherwise, muriatic acid (HCl from the hardware store) is great for removing rings from hard water in a toilet… it also dissolves all of the rest of the filth build up… it will corrode iron sewer pipes so multiples flushes afterwards is necessary to protect your pipes… just my two cents on acids.

1 Like

Thank you so much for sharing your knowledge!

It is indeed very confusing and frustrating. I think I’m going to take some jewels to be tested at the assay office to be sure of their purity, and then I’ll have some “controls” to test the acids and make sure they’re still ok. If they’re not, I’m not sure I’m ready to spend almost 100€ to buy new ones to have inconsistent results.

I guess it’s best to just save money to buy the machine and thats it, no more inconclusive tests.

use of nitric acid and aqua regia to do streak testing requires a lot of experience and skill… even with controls results could be variable… I wouldn’t take on the challenge when electronic testers are available.

However, if you aren’t going to use it often enough to be worth the cost, it might be cheaper to get your metal tested by a jewelry store or pawn shop that has one. If you do so, make sure they have claibarated their tester… everything needs to be calibrated against a known sample… machines go out of calibration also and have to be recalibrated from time to time… acid testing has the same problem… if acids sit for too long, the strength changes even if sealed…

1 Like

Thank you for sharing your knowledge!

I agree with you, I don’t think that for now, it’s worth the investment to test a few jewellery items I have and some that my customers have.

I’ll research if any jewellers shop near me test them, otherwise, I’ll just take them to the assay office and see if they can help me.

1 Like

no problem, you’re most welcome…don’t do it at home!

(ps: i’ve attempted this at home before… I have both nitric and hydrochloric acid… both are nasty stuff…fuming toxic gases are exsolved when at full strenght. 37% HCl and 68% HNO3 has to be diluted down very accurately, both give off acid gas fumes… can’t be done indoors…plastic tablespoon/ teaspoon sets aren’t accurate enough to measure out acid and distilled water… if you use US measurements, they have to converted to metric for calculations… you need to know enough chemistry and have laboratory quality measuring glassware, to be able calculate molar concentrations of acids to do it accurately…calibration against known metal alloys have to be repeated for precision (there is a difference between precision and accuracy)… In short, none of it is worth the risk nor the hassle unless you are a pawn shop… and I don’t trust pawnshops either… many try to take advantage of you. take it to a reputable appraiser in a brick and mortar store… never send anything away online… you might not get it back!

1 Like

I couldn’t edit the last comment… what I meant to say was don’t DYI at home by buying full strength HCl and HNO3 and trying to make your own acid dilutions… buying a kit with premade solutions is okay, as it avoids a dangerous hassle, however given the small number of samples that you want tested, it still may not be worth the cost… getting it tested electronically at a reputable brick and mortar store is probably the most cost effective way for you to go…at least you will be a professional reading.

Good luck…hope everything works out well…

1 Like

Thank you!

You’re right, it’s too much hassle to do it for the amount of stuff I need testing.

I’ll check with some jewellers to see if they know someone of confidence.

I did it only as a home science experiment… I have enough biochemistry background to understand chemistry as a whole…and as a whole, the experiment was a practical flop. It did work but not well enough to get reproducible, reliable information to do streak testing… also had some gold plated fine silver medical electrodes that had been discarded and given to me by the lab techs… I tried to separate the gold from the silver using HCl with dilute HHNO3… I was able to dissolve the silver and recover the gold, but the gold was thinner than gold leaf… the silver was converted into silver chloride which I tried to recover using a coffee filter… the particle of silver chloride were so fine that they passed right through… it could have been reduced to metallic silver just by heating… To DYI, it would have required micropore filters to trap very fine particles… the amount of gold and the cost of acid, even from concentrated half and one gallon bottles, plus the very high cost of micropore filters would have far, far exceeded the price of any gold recovered which would have been minimal…

I had to give up…I just melted the silver electrodes down… if assayed it would be fine with a trace of gold… diluting the acids further to do streak assays was also a flop… I couldn’t get reproducible results with known karat gold… I don’t regret trying, as it was fun to do just as an experiment… it did work in separating gold plating from fine silver… but due to DYI home technical limitations, it wasn’t worth it economically nor in the time it took to attempt it again using more refined techniques… That was my experiment in chemistry of gold and silver… it worked theoretically but not practically in cost effective terms. What I learned was it wasn’t cost effective at all…

What was cost effective, was to assay for lead in old housepaint undercoating… just using HCl and household ammonia, gave me positive results… I had to use an N95 mask to sand off the lead paint, while vaccuming the dust with a vaccum with a HEPA filter…If I hadn’t done that DYI, I would have had to send a paint chip off to a lab for analysis. The cost would not have been high but the waiting time for results would have been 3-4 weeks, too long for me to wait to repaint.

In short, I think you are much better off to have your gold assayed professionally with an electronic tester by a reputable jeweler with enough experience in its use to give you reliable results… good luck and happy assaying!

2 Likes