Just the other day, I made a little tool for sorting casting shot by

size. I like to add granulation to some of my silver pieces, and I

am too lazy to make my own. Picking through a bag of grain is

painstaking, so I turned a cigar box into a sorter. It has about an

85% accuracy rate, and dramatically cuts the labor (and eyestrain!).

This isn’t fancy, but it does work pretty good:

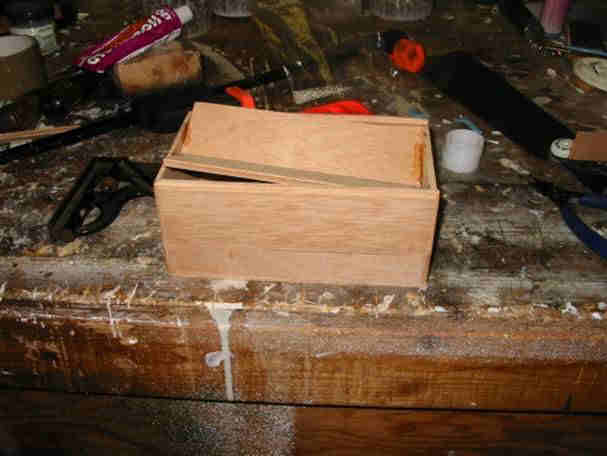

Just take a cigar box like this. It has a sliding lid and is fairly

deep (any cigar shop can provide these). Cut the bottom 1" off of

the box. This will become the sorting tray.

Trim the long end of the sliding lid panel so that it is roughly the

same length as the long opening of the box, then cut it in half.

Keep this cut as smooth as possible. Afterwards, sand the cut sides

of the lid pieces flat by placing some sandpaper on a flat surface

and sanding the cut.

Now glue/epoxy the lid pieces into the upper opening of the box you

just cut the bottom off of. This is going to be tricky, because it

involves some compound angles. This is why I use quick setting glue.

Don’t get your mitre saw out and try to make a piece of art unless

you are really certain you can work out the geometry. Gaps can be

filled with glue.

You are creating a sloping ramp, which tilts from one end of the box

down to the other, using the two lid pieces. Each lid piece also

tilts towards the other, so that a valley is formed. This is so that

a bead of casting shot will want to roll down the V-groove that is

formed by the two pieces from one end of the box to the other.

I have about a 1/2" difference between the height of the ends of the

pieces, creating a sloping effect down the long width of the box.

The pieces are tilted towards each other at about a 30=B0 angle.

However, the critical element of this ramp is not how well the two

pieces are joined together, but rather how you keep them apart.

The upper end of the ramp should have gap wide enough only for the

smallest piece of casting shot, perhaps 1/16". The lower end spreads

out to 3/16", which is about as big as a casting shot ‘clinker’

gets. So, as the ramp descends, the space between the two box lid

pieces gradually increases.

Once the lid pieces set, you can cut out strips of cardboard and

glue them into the box bottom, about 1" apart, which will form a

series of compartments for the shot to drop into. The strips just

keep the shot beads from rolling around and foiling your

organizational efforts.

Let everything dry. Go have a cigar recently liberated from the box!

Once all is set, put the top back on the bottom of the box, and go

get some sterling silver casting shot. With a teaspoon, gently place

some shot into the higher end of the ramp. The shot will roll down,

then drop through when the groove becomes too wide. Obviously, the

smaller the shot bead, the more quickly it will drop, landing in one

of the compartments in the bottom of the box. Eventually, each

compartment will fill with shot roughly the same size.

Now, this box does not have a brain, it is working on the principles

of physics. So, it can’t filter out odd shapes from perfectly rounds,

and so some flat pieces will fall through in the narrower area when

they 'should’have passed all the way to the end. As you place shot

into the groove, it helps to have a pencil or stick ready to

‘motivate’ the shot beads to move. Just don’t push straight down, but

rather just a little brushing motion. Pushing down will jam the beads

into the groove and damage the groove. Rough edges in the groove are

your enemy.

Some shot will, at first, bounce off of the bottom of the box and

leap into other compartments until a layer of shot is formed to

catch falling beads. Other beads may race down the ramp and

overshoot their intended compartment. To prevent this, place the

shot gently into the groove, a little bit at a time.

It ain’t pretty, and it ain’t perfect, but it gets the job done. I

take the box bottom to my workbench and pick the pieces out that I

need. If I needed a whole bunch of the same size, I can pick them

out and put them in a baby food jar.

As Mr. Portokalos says, ‘There you go!’

My thanks to all the fine folks who make your website such a great

resource for amateurs like me!

Fr. George Aquaro