I need to file flat 90 degree ends on sections of 3 & 4mm square wire. Although miter cutting jigs work fairly well it’s not easy getting the wire/rod to engage accurately with the square nub at the end of the slot. Does anyone know of a tool or work around that will help me get consistent, accurate, squared-off ends?

Hey Tony,

I use my miter jig for this exact purpose. I found that it takes a little experimenting to get it to work the way I want. A couple of key things (sorry if some of this is obvious): Make sure the vise is tight enough, and that the jaws and “nub” are totally clean of debris. Then, when filing, only file toward the nub so you’re pushing the stock against it; filing away from the nub can cause the stock to move.

I don’t have a photo of the perfect ends I’ve gotten, but here’s a shot of them undergoing tension soldering after filing:

Best,

Alec

Are you speaking about these mitre filing jigs?

AHA! Just me being really dumb and not looking closely enough at the jig!

Tony Konrath

I use a huge flat file , with fairly coarse tooth

The finest I can find in a foot long file , the trick is I grind off one edge from them on a belt sander ( not enough to deform the edge but enough to take the tooth off) this leaves an 90 degree angle to the flat cutting side , so I’ll eye ball the " other 90 degrees by placing my flat wire marked with a square on my angled wood pin and slide my file over the grinded side . It makes a fairly decent square angle with practice

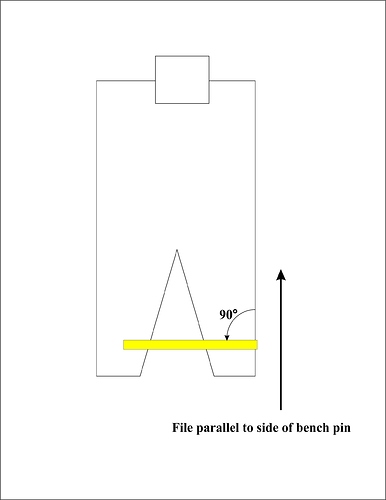

I file a notch on the outer prong of my bench pin that is at a 90 degree angle with the right side of the bench pin. Then I place the piece that needs a straight end into the notch and slide it just to the edge of the bench pin . Using a flat file I slide it along the edge of the bench pin where it just touches the piece and file it perfectly flat. Quick and easy

I am a tool guy and would like to try one of these jigs. That being said, I have filed thousands of square and angular joints by hand and eye in a small bench vise for nearly 50 years. I hold the joint up to a light and, if light gets through, I file some more. I also secure the file in my vise and run the joint up and down over the file with one side of the joint on one side of the file the other side of the joint on the other side of the file. The joint may not be square, but it is the same on both sides, so they match. I am not compelled by need to buy a jig, but I would sure like to try one…Rob

No equipment should be necessary other than a bench pin and a file…:-)…… I place the piece (be it wire or sheet) on my bench pin perpendicular to the bench pin’s edge and then file the edge parallel to the side of the bench pin. Perfect 90 degree angle every time. I should perhaps mention that I sit straight, with both feet flat on the floor, shoulders level, and shoulders square with hips. Sitting straight lines you up with your piece and enables you to ‘feel’ the 90 degrees easily.

This used to be considered a basic goldsmithing skill which all goldsmiths were expected to master. Even doing large quantities, it goes much faster than having to screw each piece firmly into a jig and then remove it. Also, you can easily remove the bur while the piece is still in place, saving yet another step.

My usual advice to newbies: save your money—practice your skills!

Janet in Jerusalem

“No equipment should be necessary other than a bench pin and a file”

I’ve been a practicing goldsmith for over 35 years. I wanted a hyper- accurate method.

I always tell my students to keep their files parallel to bench pin. I only use the mitre jig when I’m filing tubing to make tube bezels. After 30+ years, I just jam my wire in my little notch on my bench pin and file away with a big file. I don’t care if the joint is at a slight angle, as long as both ends of wire meets together in a tight butt joint. I have to admit, I do that automatically these days. Muscle memory and sheer habit.