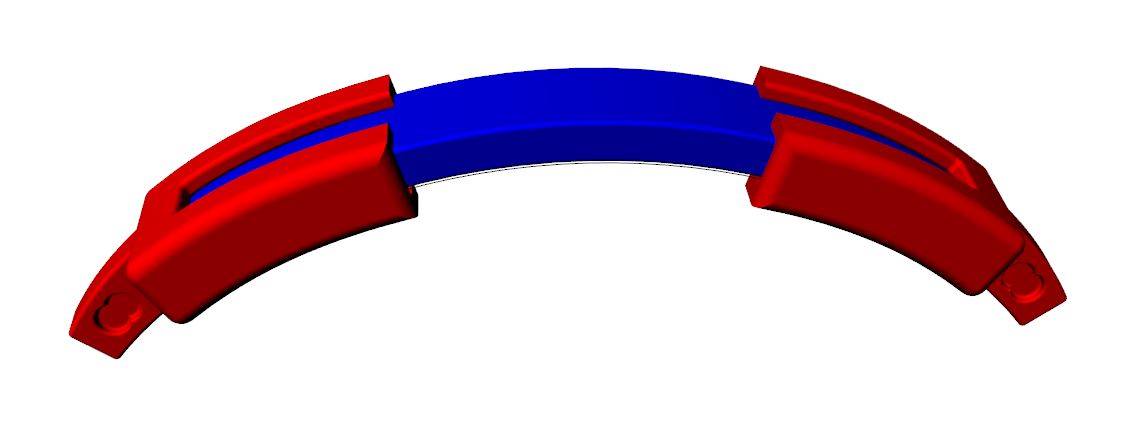

Hello, I am creating designs to be casted in sterling silver. Essentially I will have two connecting pieces that attach to a center silver bar.

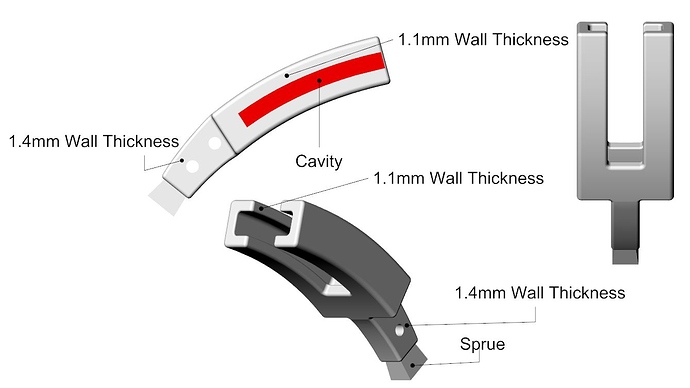

I am concerned with the wall thickness on the connecting elements. The minimum wall thickness is 1.1mm. I can increase that to around 1.3mm by shrinking the cavity for the silver bar (see image) but will that even make a difference?

My concern is the quality of the castings. Weather wax can escape from the investment, bubbles getting trapped ect.

See photos for reference. The overall dimension of the connecting piece is around 23mm long and 5 mm thick.

Appreciate the help