The term French Knot comes from an embroidery stitch by the same

name. When done properly it results in a ball of floss on top of the

fabric.

Norman

The term French Knot comes from an embroidery stitch by the same

name. When done properly it results in a ball of floss on top of the

fabric.

Norman

I found your explanation of the word ORCHID amusing and feel that you

are some one that looks beyond items. Although, I have found that

whatever these items are called, french knots, sizing balls, etc. My

mother had many placed on her good rings that were worn everyday

since her C2 fx and surgery which caused atrophy in certain fingers.

This enabled her to wear rings without them turning and being

damaged. This was atleast 30years ago. Like your sense of

humor…Keep it up

Pat fr Arkansas

This concept of sizing balls is new to me,but I find it very

interesting. On numerous occasions,I have been in a position to be

unable to resize a ring in the normal or traditional

manner,ie.,adding or taking away of shank stock because the shank was

made of patterned stock.Which has found more favor with most of you

silversmiths and your clients,the sizing balls or adding some shank

stock to the inside of the shank? Another question,do you flatten the

ball or bead slightly before soldering? Also,is 2mm (it was

mentioned) the largest you would use? I would appreciate all input,

Best wishes and thanks to all, John Barton,Images By JJ

Karen, You can see a picture of these at

http://henryjordan.com/owlring.html ,. I hope that this makes things a

little clearer.

Neil KilBane

Longford,Ireland

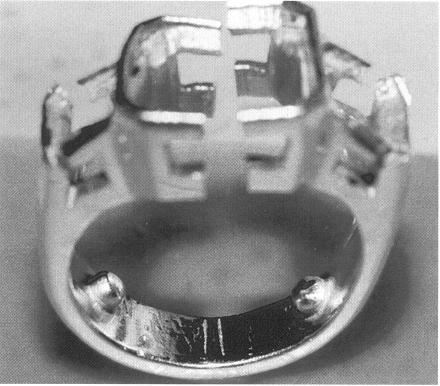

I have posted the picture of Fred Ward’s emerald ring setting for

those interested.

I am not sure if this link will work for you. But if not click on

the ganoksin.com/ftp link below and scroll to the Sizing Beads listing.

Again thanks to Modern Jeweler, January 1998 for this picture.

Norman

It seems that it would be easiest to explain sizing beads, (the term

I learned for these devices) is a picture. I have attached a picture

of Fred Ward’s infamous emerald ring setting, care of Modern Jeweler

January 1998 issue.

** Attachment Removed **

I have taken to using a 1.5 mm round bur to make a small depression

at about 4 o’clock and 8 o’clock so I can readily place the sizing

beads just where I want them, as they have a tendency to move around a

bit when the solder flows. I then ball up two rings that I wind around

a mandrel so as to keep the pieces uniform. I then sweat a small

amount of medium solder on the bottom of the beads, place them in the

little dimples and slowly heat the ring until the solder flows. This

method works really well when I have a large wet paper towel wrapped

several times around the stones to protect them from the heat…I have

already located where I want to place my beads and do not have to

struggle to find the center line of the mounting and then look for 4

o’clock…

Works for me.

JMalone

Hello Geo., The small beads go on the inside of the ring to slightly

pinch the finger, preventing the ring from turning. However, now that

you have brought up the possibility of putting them on the outside, it

sounds like a terrific design concept. The ring wouldn’t turn and it

would look cool. Have a good day. Tom Arnold

Another thing that can be used is a half spring which is a piece of

gold rolled out to the with of the shank and the thickness of about

half a mm white gold is best as it will work harden and work as a

spring. You arch the metal so that it is round like the ring. Then you

cut it to length, this is done by measuring from the 6 o�clock

position (where you would cut the ring to size it) and up to the 11

or 12 o�clock position. Round the 12 o�clock end and put a little

lever bend in it. This is so that when it is pushed back to the shank

(after it is soldered in) it will not go all the way down to the shank

and just lay flat against the shank. Know just solder it into the ring

at the 6 o�clock position. You then have a ring with a spring half

ring on the inside.

Am sure you are confused so draw a circle then draw a half circle on

the inside only touching at the 6 o�clock position and going up to the

12 o�clock position.

JB

Tom Arnold, I hadn’t thought of it as a design element until you

mentioned it. But if a person wanted to put the balls on the outside

of their ring, they could put posts instead and then attach small

gemstone, pearl or glass beads instead, dependant upon the ring style.

That is a good idea, thank you. Geo.

Maybe I"m missing something heRe: Isn’t the principle of the sizing

balls to grip the finger enough to keep the ring from turning

around, while still enabling the wearer to slide it over a large

finger joint? If the sizing balls were on the outside of the shank,

how would they keep the ring from turning unless they were heavy

enough to act as counterweights? Dee

Another comment on the ever expanding world of Sizing Balls: This

modification is included in “Ring Repair,” the first in my

Professional Jewelry Repair Series. The book includes real life

repairs made to rings, plus lots of explanations of other ring

procedures, with dozens of close up color photos and over a hundred

sketches. There is a chapter on installing Sizing Balls, exactly as

discussed on Orchid. In addition, among the 15 chapters, there are

projects on installing a spring insert and an adjustable shank, all

applicable to arthritic fingers or people who have markedly larger

knuckles than the rest of the finger. Also included are simple to

complex projects on sizing up and down in gold, platinum and silver

as well as soldering rings together, adding a bi color shank and

more. Take a look on our website for about this book. Go

to www.revereacademy.com and go to the page on books and videos. Alan

Revere

Michael, I used that type of sizing at one point off and on depending

on the customer. But I had a 78 year old female customer come in one

day in obvious pain. She had this type of sizing done on her wedding

band and when she went to do her dishes she tried to remove her

ring. She buried the loose edge into her finger and then to make it

worse pulled on it! The poor thing was freaked when she came in.

She’d been to the doctor and they wanted to use a pair of heavy duty

diagonal cutters to take it off which would have destroyed her ring.

She told the doc’s no way and left. So when she got to my shop she

was in a lot of pain. I didn’t want to hurt her anymore and was

afraid I’d make it worse but she told me I “had” to do it. So we got

her as comfortable as we could and I used a manual ring cutter to cut

it off. Then we drove her to the emergency room! She ended up with 4

stitches and one hellava sore finger. From that day forward I have

never used that type of sizing again.

Just my opinion and hey, I could be wrong Keep it Shinny, Matt the

Catt

Am sure you are confused so draw a circle then draw a half circle on the inside only touching at the 6 o�clock position and going up to the 12 o�clock position.

I generally prefer to install these so the solder joint is at about

the 10 o’clock position, with the C shaped spring going down and

around the finger to about the 4 or 5 o’clock position. The

difference is pretty much a matter of choice and the design of the

ring. My way, the top of the ring is held down onto the finger, which

I feel looks better in wear. Your way keeps the shank of the ring up

tight to the finger, and any gap is then at the top. Six of one, half

a dozen of the other. But we do, sometimes, do a varient which works

very nicely. In this, the shank of the ring must be about 3mm or

wider, and at least about 1.5 mm thick all the way around. It is

grooved out on the inside with a shallow (.5 to .7 mm deep) flat

bottom channel Routed into the insde of the shank all the way around.

Now a spring, such as you describe, but shaped more like a horseshoe,

is soldered in at the bottom (the six o’clock position". it extends

up on both sides to the 10 and 2 o’clock positions, where those loose

ends are then slightly bent back towards the shank. As described in

the prior post, those bends serve to ensure some spring, but also to

see that the insert engages the groove on the inside of the ring when

it’s depressed. What this does is that when putting on the ring, the

spring is pressed into the channel, so that the sideways friction of

the finger cannot push/bend the spring out to the side of the shank.

Plus, it looks a lot more tailored when done.

Peter Rowe

Hi All. During all of this discussion, noone has mentioned square

rings for the arthritic fingers. I bought a squarish mandrel

(probably the one Rio Grande calls “roundish square”) over twenty

years ago and they work great. I also sometimes build up the lower

corners on the outside to produce a more pronounced square. This is

especially effective to prevent rotation of rings with larger stones.

HTH, Roy- in the Highland Lakes area of central Texas

Dee asked:

if the sizing balls were on the outside of the shank, how would they keep the ring from turning unless they were heavy enough to act as counterweights?

I once did a ring that was essentially round but with 4 evenly spaced

nodes on the outside of the shank. I wore it for a number of years

and it never turned, even though the nodes were raised no more than

1.5 mm. It isn’t the weight. I think it is because fingers are

aligned so that they naturally touch each other in the resting

position, plus the little bit of webbing between fingers working as a

barrier is enough to prevent rotation.

MP

Hi Roy; I often recommend rings with square corners on the bottom

outside shank to keep rings with heavy tops from turning on the

finger. Haven’t tried rings with square holes yet. By the way,

anyone out there know where I can get a rubber ring mandrel? Rio

used to carry them. I never tried one, but I thought they might work

for square rings, or rings with odd shaped or distored shanks, like

heavy class rings that get sized up a lot but can’t be rounded out

again. Also, as per the “arthritic shank” solution, there are also

shanks you can make or buy that are hinged at the sides and slide

open and closed. I’m not talking about the “finger-fit” type with an

actual clasp in them. These kind, the shank on the lower half of the

ring is made of two thinner strips that slide past each other with a

thing on each end like the part on a belt that is past the buckle

that holds the tip of the belt from flapping about. I also have seen

a think where a small tube is soldered on the outside bottom of the

shank, about 5:00 o’clock. A wire passes through the tube, forming a

long rectangular frame, the other end of which clips down over a

small nib of metal. It passes either side of the shank when closed,

thereby squaring off the bottom of opening in the ring.

David L. Huffman