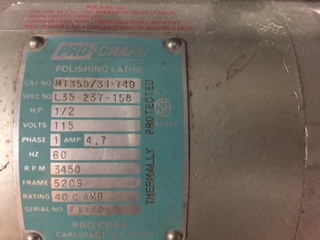

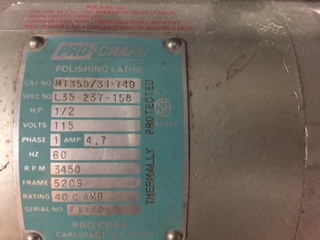

While trying to put new buffs on the right side tapered spindles of my older model polishing motor, the tapered spindle came off. Now it doesn’t stay on and has spun off, twice. Please help me figure what’s happening.

Here’s a pic of the right side spindle that came off:

Hi Suzi,

Is there a set screw, probably an allen head, missing? And is the spindle the right thread for the side of the motor you are using? You probably are experienced beyond these questions being necessary but I can’t tell you how often i have had electrical problems that my wife solved by plugging in the wire.

Don Meixner

---- Susi Wells orchid@ganoksin.com wrote:

2 Likes

Don’t forget the Allen Screw has to tighten onto the “flat” on the motor shaft.

As I recall, not all spindals lock on with a set screw. The brass spindals on my Balfour motor in the QuattroPro system are a press fit brass, with no set screws.

If yours has set screws, gently tighten them on the flat of the shaft, and check to make sure they run true, if they do not, re-adjust the spndal until it is, then tighten the set screw(s).

If no set screw:

Try tapping on the “pointy end” gently with a soft mallet, turn on the machine, and make sure that the spinal is running true, if not true it up, then when you are certain that the spinal is running true, strike the pointed tip harder with your mallet, to really set the spindal in place on the shaft.

It is also possible that the spindal may be worn, and should be replaced.

Looks like a friction fit tapered spindle with no set screw. Clean off the tapered shaft and inside of the spindle with fine abrasive paper or cloth. Look for any raised metal edges or burs and lightly sand ithem away. Check with the manufacturer about using a lubricant, but I doubt that they will say use one. Carefully push the tapered spindle on to the shaft. Carefully strike the end of the tapered spindle straight on with a rawhide mallet. This should engage enough taper to create the friction fit. The collar with the handle is used to remove the tapered spindle. Turn it counter clockwise and it will advance until it hits the spindle. Keep turning and it will push the spindle off the shaft. Good luck…Rob

I just realized that my post above says that the polishing lathe motor I have is a “Balfour”, rather than “Baldor”. Typo, sorry.

I cannot seem to edit, to correct it.