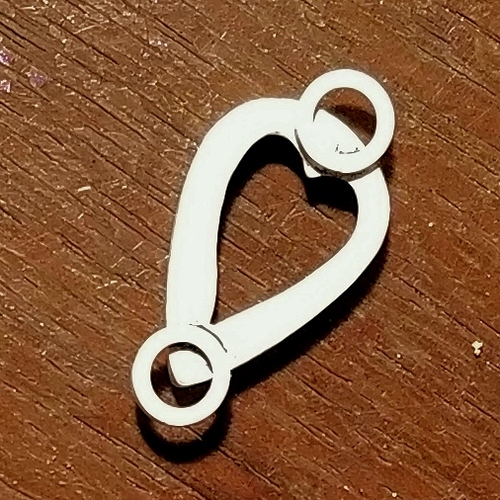

I made a bezel, and soldered a jump ring on either end (where I will be attaching cords to make a bracelet for my niece).

Many lessons in metalsmithing, and this time I learned that you should see the work you are doing, and not solder from behind, simply trusting that you’ve set it up correctly. I thought it was a good method, because it kept the assembly level.

Anyway, my question is, can I re-melt the solder and sliiiide those jump rings off? Or do I have to snip, saw, and sand? The rings are 16 gauge square wire.

Thank you.

It depends on what grade solder you have used, easy solders will run a second time but some harder solders will not. Next time you need to do a job like this consider using titanium soldering clamps, you buy strips and shape them how you want, I would use clamps shaped like this for holding that type of rings in place for soldering.

Thank you for that tip, James. I have seen those titanium clamps somewhere before, and it does seem like a good idea, as placement is always a challenge.

I think I used medium solder for the rings. I guess I’ll try to protect the bezel itself, and just give it a try to heat and pull. Otherwise, for this one I’ll re-fashion it by cutting and sanding.

By the way, the hole will be pretty with a polished labradorite peeking through the heart opening - it is the back, so a secret for my neice, the wearer.

Thanks!

Yes, you can do it…use lots of flux. try to secure the base, then heat and slide

I suggest holding the ring with a third hand and using a solder pick to

gently pull down on the rest of the assembly when it looks hot enough.

Noël

Thank you for this tip - I will slather it up, and also use ochre on the joined components I do not want to move.

Sounds like a good idea, I will definitely give that a go. Thank you.