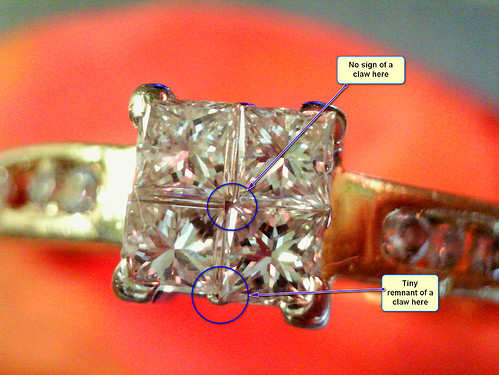

I have a diamond ring that needs the claws retipping. Trouble is, I don’t know how how the setting works. The four square-cut stones seem to be held only by the four (obviously worn) external corner claws, but that’s all. There is no central claw at all, and, although there is an indication of a bit of a claw on one edge, the other 3 have totally worn away. I’ve never seen a setting like this before, what am I missing?

This is an invisible set. These are special cut diamonds that have grooves cut just below the girdle. Then there is a rail system just under the diamonds that the grooves lock into. You should be able to see it if you look from the side. You should also be able to build the V up on top of the diamonds, just be careful not to press to hard and lift it out of the rail.

There was a jewellery company here in Toronto that gave up making their own “invisibly set” line of merchandise, why? There were hundreds of pieces in their line, why? There were just too many problems with this kind of merchandise. So be it with everyone here in this forum, just be very careful with these repairs.

They told me that once you heat up your ring just don’t water cool off your ring. Please let it SLOWLY COOL DOWN. This rapid cooling will cause problems. We all suggest getting a “customer, sign-off” as not to be responsible for stone cracking while being in for repairs!

Everyone here just now says “that these rings are rings from hell” Some jewellers now just refuse to touch them, period!

Thanks Angie, that’s a great help.

Do you think I’m right in assuming that the 4 stones were inserted onto their rails by sliding them diagonally to the center, and then ‘locked’ by the corner claws? And that the missing claws on the sides are of no consequence?

I will only work on Invisible Set jewelry under protest and after getting a clear understanding from the jewelers who I do work for that I am asuming NO responsibilty.

I do not even want to clean this type of jewelry in the sonic. I have experienced many instances where someone has already worked on these items, and resorted to using cement to get them looking like they are wearable.

To me these are a ticking time bomb, and I prefer to not have one in my hands when it self destructs!

Yes, I think that is how they are set. And a lot of time, jewelers will flow a little solder into the side to tighten the stones if they are loose. If you press too hard on the V, the stone could pop out. And I agree with the comment that they can be a nightmare and most places that attempt to repair them do not guarantee the repair.

Thanks Angie, and to all that have responded with really useful advice. I’m treading very carefully with this repair.

Since I have a laser, and I can weld without using the intense hear from a torch, if I were to be asked to do that repair I believe that it would go fairly smoothly.

Using a torch risks flowing solder you cannot see, under those stones. I would not attempt this repair using a torch. Period.

First examine the ring VERY carefilly from all sides, and try to see if the stone are secured by cement. ( it hapoens a lot, when stones have become loose)

I do not think that the “missing” prongs were ever true prongs, and that they are just a part of the framework below the stones. The stones are held from below by metal forced into the grooves cut below the girdle, and then secured by those 4 corner Vs.

If you can rebuild the 4 Vs without loosening the diamonds, this repair should be possible, but you are rolling a set of loaded dice, and they are not loaded to throw winning numbers.

Many times Laser soldering can be a life-saver. My independent jeweller who has a laser praises the day he bought his machine.

He can even laser-solder on Genuine Emeralds and holding that ring in his finger tips.

No matter what you do, please remember to get that item clean before you use any laser or torch!..”Gerry, on my iPhone”

The laser is not the answer to every problem, but it is a God-send for some situations. I probably use my laser and the torch @50/50, and often on the same project.

It certainly is a major asset when high heat is your enemy.

For a repair such as in this thread, I feel that the laser is the only “heat source” I’d let near that ring.

Thanks for the suggestions. Luckily, I have a PUK welder, which has similar capabilities to a laser.

Yeah, hard pass on these sort of rings.

The stones are a special cut where a groove with an undercut is cut into the pavilion on parallel sides. The setting has metal ‘rails’ that the stones then sit on in relation to the pavilion grooves. The stones are then pressed down onto the ‘rails’ causing the metal to enter the groove and then mushroom out filling the undercut. This locks the stone in place similar to doing gold inlay in engraving. The stones are not slide onto the rails. This setting style is difficult to do correctly. If too much pressure is applied, the edge of the stone will snap off at the groove since it is the weakest point in the stone. If not enough pressure is applied, the metal ‘rails’ won’t deform and lock the stone in place properly. The outside prongs are not needed to hold the stones in place if they have been set correctly. They serve as a kind of backup to the rails in terms of keeping the stones in place, they act as ‘bumpers’ for protecting the corners of the stones, and it works like an illusion setting tricking the eye into believing the center is one large stone and not multiple stones till a closer look is taken. Any small prongs added in the center of the sides of the setting are post manufacturing and have been done as a repair to tighten the stones. It is a terrible stone setting technique and as many people have said, a time bomb in terms of when it will break/have issues, not if it will. Avoid these jobs if possible!!